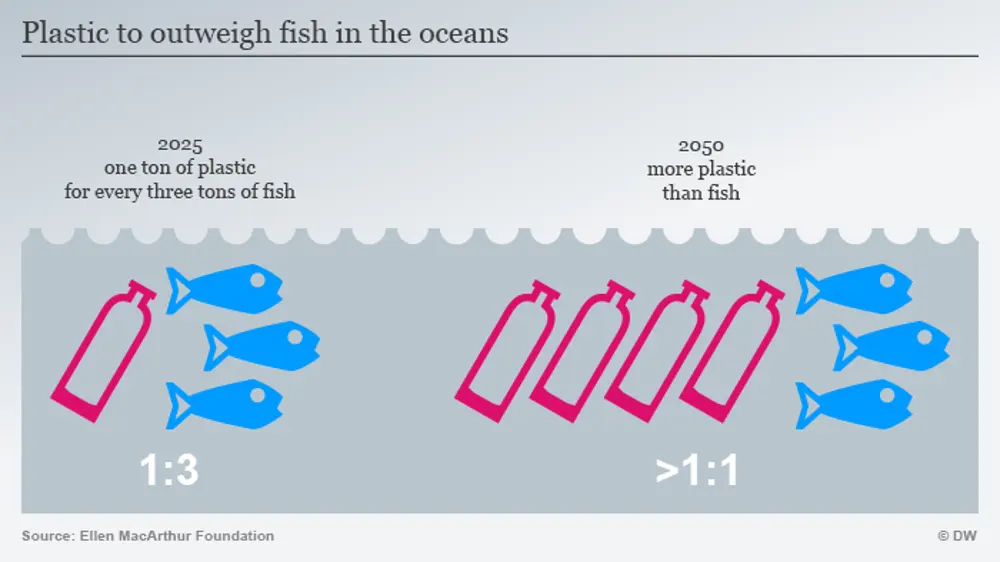

By 2050, there is predicted to be more plastic in the ocean by weight than fish. Learn about the institutions and organizations taking a stand.

The Plastic Trash Crisis

Eliminating plastic usage, from plastic bags to straws, has caught the attention of many major corporations. Though it may be appease customers, this pressure to change is ultimately coming from the impending plastic trash crisis.

It is estimated that, by 2050, the ocean will have more plastic trash than fish in weight! This is problematic since 3D printing is becoming popular and finding its way into homes and businesses across the world.

To combat this problem, several laboratories and organizations are working on turning plastic trash back into 3D printable filament. In addition, several products exist that can assist with the collection of existing plastic trash in the ocean. Let’s take a look at some of these projects!

At Duquesne University, students Karli Sutton and Alexander Evans are recycling PLA into useable filament. Conveniently, their source of PLA is biodegradable drink cups from the campus dining service, known as ParkHurst.

The students gather the cups through periodic recycling events during the school year. Then, back at the lab, the cups are ground into small particles using a Ninja blender. This material is sieved into a uniform size and added to the Filabot recycling system. The process involves a complex series of sieving, blending, grinding, and printing the material for various biomedical uses.

Their focus is to use the recycled plastic for orthotics and prosthetics research. Also, there is research into its use as a water filter for removing harmful levels of fluoride in drinking water.

University of California, Berkeley – Recycling 3D Prints

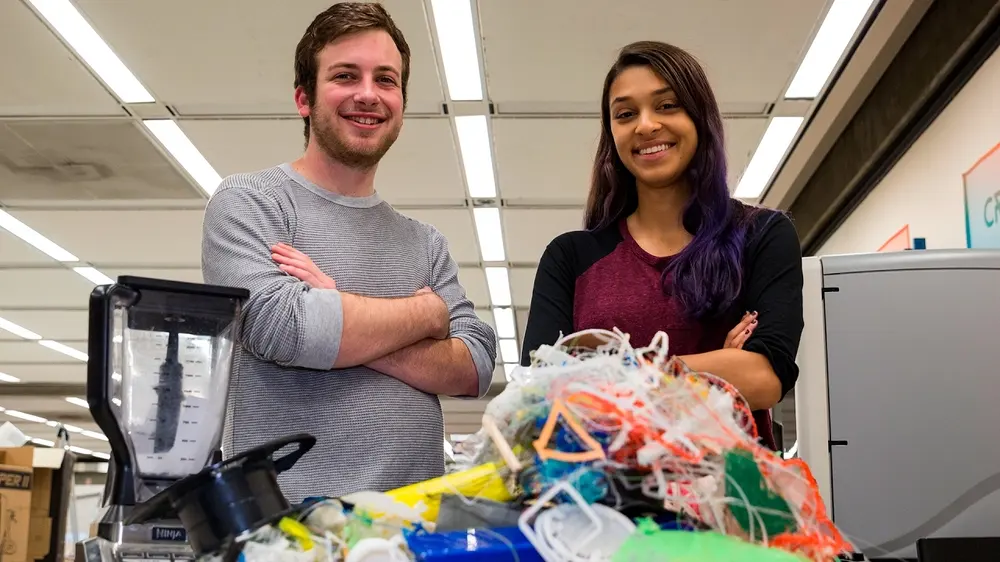

At UC Berkeley, student researchers Nicole Panditi and Scott Silva have developed a method to recycle printed PLA parts. Their method uses a Ninja blender to grind up the plastic into small pellets. These can then be introduced into a Filabot recycling system to be re-extruded into useable plastic.

Over 600 lbs of 3D printed waste is created each year at UC Berkeley, all of which can now be recycled. One key aspect is that virgin PLA must be added to the process during each recycling round. This ensures consistent mechanical properties and useful printability.

More information on the process can be obtained at the Student Environmental Resource Center website.

US Army Research Laboratory – Plastic Recycling

Research at the Army Research Laboratory by Dr. Nicole Zander is focusing on recycling water bottle plastic. This plastic PET, can be used for military applications, such as aircraft parts and medical devices.

Unlike with PLA, recycling PET into 3D printable filament requires more work. According to Dr. Zander, “recycled polymers have a variety of different additives, fillers, and dyes and may have experienced different processing conditions – even for the same polymer type.”

This type of plastic recycling also has applications outside the miliary. In principle, it could be used to clean up existing landfills with appropriate cleaning and reclamation of the waste plastic.

Filabot – Recycling Services

Filabot has partnered with TerraCycle to provide filament recycling for any type of 3D printable plastic. Their method allows a customer to pay for a box that has pre-paid shipping to the recycler. There, TerraCycle will recycle the plastic safely.

The main drawback to this method is that the boxes and shipping tend to be rather expensive (a small box is $85). This aspect makes it a useful, yet expensive method to recycle used plastic.

In addition to recycling, Filabot has engineered a process to recycle filament spools back into 3D printable plastic. The MasterSpool project aims to change the way that 3D printed filament is delivered to an end user. A user can 3D print the spool, which can be refilled using minimal-packaging spooling as refills. In this way, printing a MasterSpool out of spools could become a closed loop that prevents any waste material from reaching the ocean.

Individual Use Recycling Systems

Several companies have created devices that can be purchased so that an individual or a company can recycle their own 3D printed plastic parts. Some can even recycle plastic trash back into useable 3D printable filament. Here are a few examples:

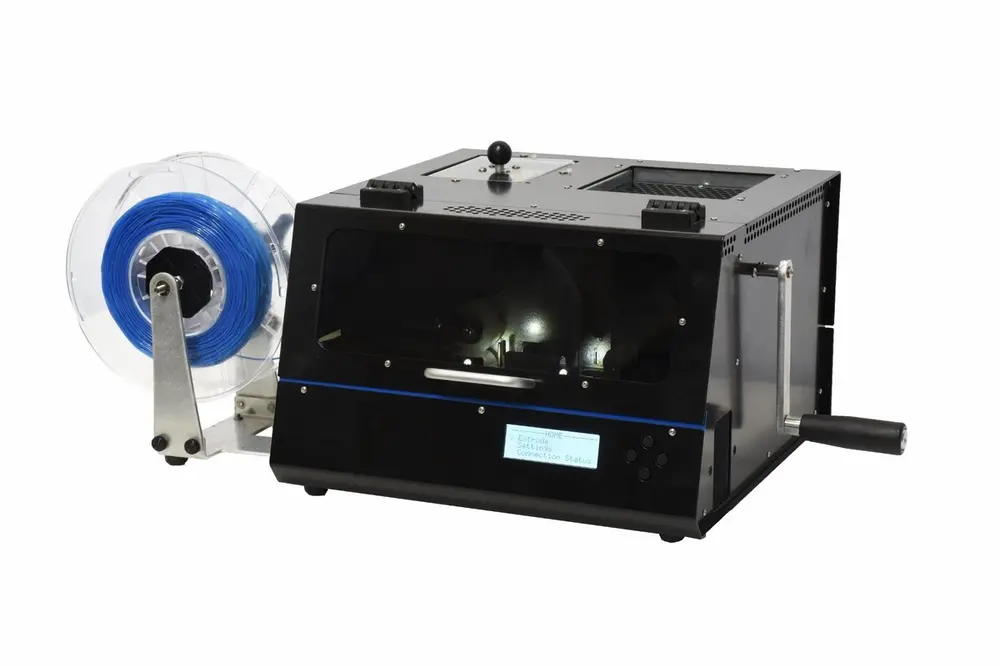

- The Protocycler+ (once an Indiegogo campaign) has generated significant interest since its launch. This is mainly because it is an all-in-one recycling system that currently costs only $1,700. The device acts as a manual grinder, spooler, and extruder to create recycled filament in one compact device.

- Filabot EX6 and EX2 extruder setups are used by labs and individuals alike, including the UC Berkeley and Duquesne groups. Despite their relatively high cost, the Filabot is capable of recycling nearly any household plastic with the exception of PVC (due to safety concerns).

- Filastruder is a popular brand of filament recycler with a low price and a wide range of useable plastics. Even PET (think, plastic soda bottles) and other consumer level plastics can be recycled. The only drawback to this system is the lack of a grinder, which is critical for being able to recycle plastic.

Collecting Ocean Waste Plastic

There are several methods of collecting waste plastic from the ocean, however, one of the most deployable is the Seabin. The Seabin is a bucket connected to a pump system that literally sucks the floating plastic ocean trash into the bin.

Currently, due to the Seabin’s requirement of being connected to a water pump system, it only works in marinas. Nevertheless, the land near the shoreline is one of the places where trash like plastic bottles generally gathers. According to Richard Thompson, head of the International Marine Litter Research Unit, we should spend 95% of our effort preventing trash from entering the ocean, and the Seabin represents a great way to do just that.

Once plastic trash has entered the ocean, cleanup efforts become significantly more expensive and difficult. Nevertheless, that’s the goal of the Ocean Cleanup Project. Many pieces of plastic trash float on the top of the ocean. A vessel encircling the trash with a large flexible pipe can drag the trash back to the shoreline for recycling. This works because the pipe doesn’t trap fish, which can swim deeper to escape the reclamation.

These efforts certainly help, but not all plastics float on the surface of the ocean. Only by attacking the root of the plastic problem can lead to long-lasting change, which current cleanup methods cannot do.

A World Without Plastic Trash

“From the cradle to the grave” is an expression often used when talking about the production and use of a product. For plastics, this lifecycle resembles that of a virus – a constantly multiplying supply that will soon overtake us all.

We should all do our part and invest in technologies and companies that can help us recycle, reduce, and reuse. Some day, we’ll be able to close the loop and end this problem once and for all. What was once one man’s trash will literally be one maker’s treasure.

Feature image source: UC Berkeley / YouTube

Source: 3D Printing Sustainability – Solving the Plastic Trash Crisis | All3DP