3D printing technology makes functional, beautiful product prototypes accessible to everyone. Learn how to get started now.

If you’ve ever tried to pitch a great idea for a new product or invention, you know your impassioned description just isn’t enough. A detailed sketch or video is better, but nothing wins people over like a prototype they can hold in their hands.

Today, 3D printing is the number one way product prototypes and models are made, and for good reason. It’s faster, cheaper, more accurate, and has a better presentation value than carving foam, forming clay, or any of the manual processes once used to whip up very hand-made-looking concept models.

A good prototype gives your product more appeal that’s sure to impress your boss or investors. Plus, because 3D printing is so easy and affordable, there’s no excuse anymore for using tape and glue.

3D printing, whether you do it yourself or use an online service, enables you to bring your idea to market faster. Depending on your product, you can print a working prototype in a matter of hours, enabling you to test for functionality and aesthetic appeal, redesign, and print new iterations the same day.

In this guide, you’ll learn all you need to know to 3D print your product prototypes, including which materials to select, whether it makes sense to buy your own 3D printer (and which one), and how to select and use on-demand 3D printing services to get your prototype printed fast and delivered to your door.

Prototypes for Product Development

Long before you get to the point of presenting your idea, you test whether or not it will actually function. In theory, your product is going to change the world. First, putting it to the test will reveal where it needs more work.

3D printing enables you to create great-looking models but also fully functional, working prototypes strong enough to test in the field under real-world conditions. Practical testing is the essential step in revealing problems you may face in manufacturing your product and in how customers will use your product. Real-life testing and analysis help you bring better products to market.

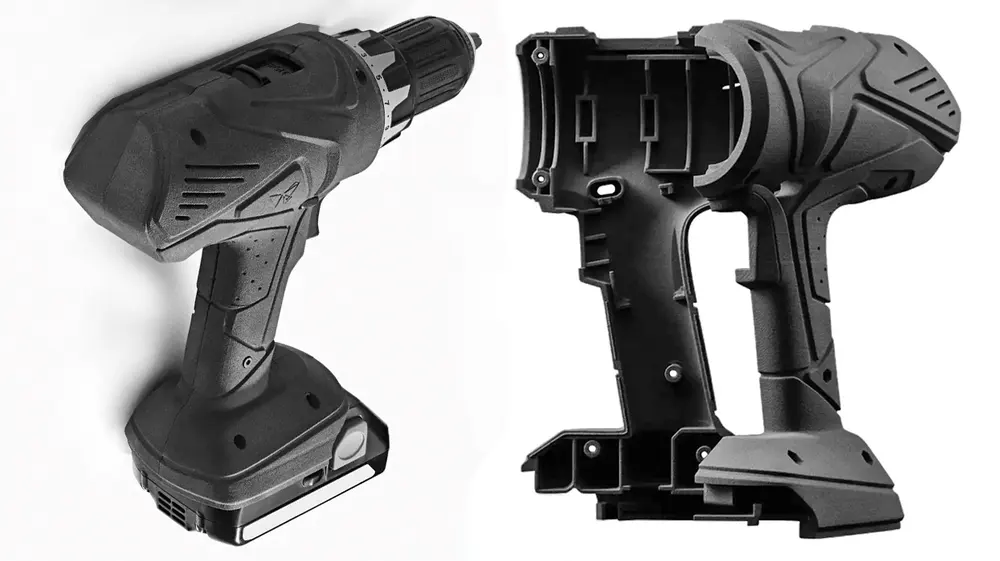

Many product designers 3D print initial design prototypes in basic plastic, then move up to engineering-grade materials or even 3D printed metal for functional testing.

Let’s look at some examples.

Full-Size & Functional

Black Diamond Equipment makes innovative climbing, skiing, and mountain gear known for comfort, durability, and performance. All of their products go through a rigorous design, testing, and iteration process before they come to market.

The company has used 3D printing in its design workflow for years to create prototypes or scaled-down models in-house. Larger full-scale prototypes were often outsourced to a prototyping firm because the standard size of desktop 3D printers was too small until they found the Formlabs Form 3L — a stereolithography (SLA) 3D printer with a build volume that can handle human-scale prototyping of products such as helmets and the mountaineering shovel pictured below.

Affordable Iterations

Solo entrepreneur Khalid Bou-Rabee took a different approach to test if his new home weight-lifting workout invention would actually function.

“Computer simulations can be very accurate, but nothing can replace real-world testing. I needed prototypes,” he told All3DP.

At first, the young entrepreneur thought he’d order a stainless steel prototype, but changed his mind quickly when he was quoted at over $1,000 for a single CNC machined metal part. He then turned to the 3D printing service marketplace Craftcloud which provides instant quotes on any uploaded digital design. Through this platform, Bou-Rabee discovered a strong-as-steel polymer alternative and found a 3D printing partner he could afford to produce multiple iterations, which enabled him to test his product and bring it to market within a year.

Functional testing often means creating a prototype in the same material that the final product will be manufactured in, such as carbon fiber or stainless steel. With the ability to quickly 3D print stainless steel parts both in-house and through on-demand services, design teams can produce functional prototypes for testing, such as the 3D printed aluminum bicycle frame from Canyon pictured below.

3D Printing Materials for Prototypes

The materials you can 3D print your prototype in are virtually limitless, spanning soft silicons, metals, tough plastics, conductive copper, sustainable wood, and even chocolate. There are thousands of 3D printing materials available and methods to 3D print with multiple materials at once.

If you’re unsure which materials would be best for your prototype, we have dozens of in-depth guides here on All3DP that explain the various materials, their properties, and what they’re most commonly used for. We’ve linked a few in the list of materials below.

Common 3D Printing Materials:

You can also check out the material guide at 3D printing service Craftcloud, which specializes in prototypes.

Below, we put the basics in a quick chart.

| Property | Materials | Cost | 3D Printing Technology* |

| Hard | PLA | Cheap | FDM, SLA |

| Flexible | TPU, Resin | Affordable | FDM, SLS |

| Clear | Resin | Affordable | SLA |

| Durable | Nylon, Carbon Fiber | Moderate | FDM, SLS |

| Sustainable | Recycled PETG, Recycled PLA | Affordable | FDM |

| Heat Resistant | Flame Resistant PLA | Affordable | FDM, SLS |

| Soft-Touch | TPU, Flexible Resin | Moderate | FDM, SLA |

| Colorful | Resin | Expensive | Polyjet, Inkjet |

*technologies described below

Types of 3D Printing for Prototyping

There are more than a dozen types of 3D printing. All of which are used for rapid prototyping. Finding the perfect match for your product is a matter of balancing cost, speed, material, part complexity, and whether you want to print it yourself or outsource it to a service. In general, the most-used technology for prototypes in plastics is fused deposition modeling (FDM) because it’s the easiest and cheapest.

If you outsource your prototype to a service, you may be asked how you want it printed. Below we cover the basics.

| Need | 3D Printing Method | Cost |

| Fast | FDM | Cheap |

| Economical | FDM | Cheap |

| Exact Detail | SLA, SLS | Affordable |

| Metal Parts | FDM, SLM | Moderate |

| Multiple Parts | SLA, SLS, MJF | Moderate |

Fused deposition modeling (FDM)

FDM, which uses rolls of plastic filament as the material, is the most widely used 3D printing method for prototypes because of the variety of available materials and the low cost. Whether buying a machine or ordering through a service, FDM is the most economical. But FDM is also an industrial method. Manufacturing-grade FDM machines can print with engineering materials, like carbon fiber, in fine detail and super strength, so don’t think of it as just the cheapest option. You can also print metal using this technology and metal filament, which is actually metal powder-infused plastic filament.

If you want to purchase your own FDM 3D printer, check out our guides below to the top printers in this category.

Stereolithography (SLA)

For parts that need to have a slightly more smooth service than FDM right from the printer or more fine details, product designers often turn to 3D printers that use stereolithography (SLA) technology, also called resin 3D printing. These machines use liquid resin as a base material and are the go-to choice for clear products and parts with fine features, such as jewelry.

As with FDM, there are budget, studio, and industrial versions of resin 3D printers capable of painting in various materials ranging from durable to flexible to industrial. If you want to purchase your own, check out our guides below to the top printers in this category.

Selective Laser Sintering (SLS)

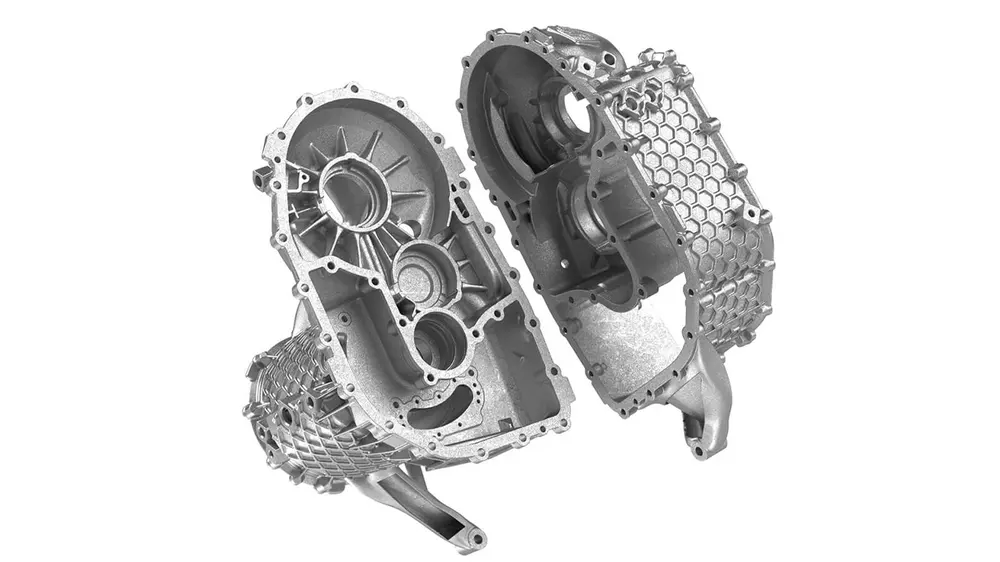

SLS, also called laser powder bed fusion, is a 3D printing method that uses a laser to melt together powdered polymers layer by layer. You’d turn to this method for functional prototypes you intend to install in engines or machinery and put them to the test. SLS produces finely detailed parts in materials, like carbon-fiber-filled nylon, that can withstand harsh conditions.

SLS printers can print many parts at once, so it is also the ideal choice when you need a dozen or so parts or when you want to print many slightly different iterations in one go. SLS is used for final parts as well as prototypes, which makes these machines popular at machine shops and manufacturers.

Metal 3D Printing

If your final product will be made of metal, then you need a metal prototype. Any of the metal 3D printing technologies will be more expensive than the polymer options, but they will be faster and cheaper than any traditional methods for making metal parts, such as casting or machining.

Compared to CNC milling stainless steel or injection molding, 3D printing is ideal for prototyping because there’s no wasted material or the need to create a mold or cast. Plus, there are no minimum quantities when ordering metal 3D printed parts from a service provider.

Final Prototypes for Presentation

You’ve perfected your product. It functions as expected, and now it’s time to 3D print the final version. Here is where full-color prototyping often comes into play, along with various post-processing options to make your prototype look as much like your final version as possible.

Likely, your final product will not be all one color. Unfortunately, most 3D printing methods only print with one or two materials (in one or two colors) at a time. Although some can print in four or six colors at once — check out our guide to multi-color 3D printing.

If you want a full-color prototype, you have two options: paint or full-color 3D printing.

Paint & Post Processing

Most 3D printing materials take paint very well, and there are various techniques. We have a handy guide that covers all you need to know about smoothing, priming, and painting your prototypes, plus how to get crystal clear parts that represent glass.

Full-Color from the 3D Printer

If you’re not handy with a brush, there are full-color 3D printers that offer thousands of color options and can even match Pantones precisely. There are only a few companies that make full-color 3D printers, so if you’re using a service, look for Polyjet printing from Stratasys, ColorJet from 3D Systems, or Inkjet by Mimaki.

PolyJet from Stratasys, for example, is used by product designers worldwide to prototype final products in exact colors and even textures. Just take a look at this functional perfume bottle prototype above printed as one piece on the Stratasys J850.

Full-color 3D printers produce astonishing results, but they’re pricey. Ordering from a service makes this technology far more accessible. But if you’re in the market for one for your own in-house 3D printing lab, check out our full guide comparing the three main brands, which details the technology, printers, and processes.

Buy a 3D Printer or Outsource to a Service?

Establish In-House Prototyping

The upfront cost of a 3D printer can feel intimidating, but, depending on how much you prototype, the machine can pay for itself in just a couple of weeks or months when you compare it with what you’d spend on outsourcing or alternative production methods.

There are hundreds of great brands of 3D printers, and we have hands-on reviews of the best here at All3DP. You can start 3D printing on your own with these machines practically right out of the box. Plus, a good, basic machine can cost as little as a few hundred dollars.

More sophisticated machines that will print with more durable materials start around $3,000 and can also be very easy to use but require some onboarding, which is often provided by your equipment reseller.

Today, companies that prototype often, such as industrial design firms, have 3D printers in-office as standard equipment.

“At this time, in product design, 3D printing has become a tool of the trade,” says David Block, principal of Studio Redeye in Brooklyn, New York. “If you do not have a 3D printer, and you are in the product development space, you are behind,” echos Jonathan Thai, co-founder and partner of HatchDuo in San Francisco.

But which machine to buy?

All3DP is the world’s foremost authority on 3D printers — we use them every day, we test them, we track them, we talk to the people who design and manufacture them, and we create unbiased guides to the best options.

The guides below will walk you through how these machines work, what materials they use, and how to find the best fit for your needs.

Outsource Your Rapid Prototyping

Getting your prototype 3D printed today is as easy as uploading your digital file to a service and then waiting for your doorbell to ring. You literally don’t need to know anything about 3D printing. But of course, a little bit of knowledge can lead to better material and technology choices.

Here at FacFox, we provide versatile online 3D printing services for you to pick from. When you upload your 3D file to a 3D printing service, you’ll get a quote either instantly or a little later by email.

When it comes to material cost, it’s no leap to say that an item printed in PLA will cost significantly less than the same item in sterling silver. Ideally, 3D printing services publish a list that reveals how much a certain amount of the available materials cost. Your price, or rather, the price of material required for your job, is calculated by multiplying the material cost by the volume of the 3D file.

Although 3D printing services are highly automated and use sophisticated software to facilitate every stage of production, there is still some manual labor involved. For instance, after printing, the parts are cleaned, sorted, and packaged. The final cost of a printed item reflects this labor, a part of the “service fee” that is charged per item or order.

Another factor that must be considered to understand how 3D printing services calculate prices is finishing: the sanding, dying, polishing, and other post-processes that help get the most out of your 3D prints. However, since they are often done manually, they will increase the final cost.

In processes like SLS, the biggest driver of 3D printing cost is neither material nor labor but machine space. 3D printing services stack models from various orders together to print as many parts as possible in one build. Hollow parts can sometimes accommodate smaller parts. This process makes 3D printing more cost-effective for 3D printing services. In turn, they pass on the part of the money they saved. So, the shape of your 3D file can directly influence how 3D printing service prices are calculated.

Of course, it takes someone to deliver the finished piece to you. Companies like Shapeways, Sculpteo, and i.Materialise usually work with local subcontractors. The 3D printing file gets transferred to them to be 3D printed. Then, after successful completion, is shipped.

It makes sense to take a look at shipping costs, as they can greatly differ. Some 3D printing services charge up to 100 percent more than others for handling and shipping.

Especially for prototypes, look for companies that pledge or certify to safeguard your intellectual property.