The digital age, fueled by artificial intelligence and an insatiable demand for data, is upon us. As data center requirements surge by an astonishing 400%, a critical question arises: how will traditional manufacturing methods cope? The sheer volume of computing power needed necessitates an equally massive cooling capacity.

In this context, improved cooling efficiency isn’t just a benefit; it’s a necessity, translating directly into substantial energy savings. As pioneers in 3D printing, we must ask: can we fundamentally reimagine the construction and cooling methodologies of data centers?

The answer, emphatically, is yes.

The challenge before us is immense. Traditional data center infrastructure, built on conventional manufacturing and cooling paradigms, is struggling to keep pace with the exponential growth of global data demand.

Modern data centers demand not only greater efficiency but also enhanced sustainability and rapid deployment capabilities. These are precisely the areas where traditional approaches are proving inadequate.

Additive Manufacturing: A Key Solution

Additive manufacturing technology is emerging as a critical catalyst in addressing these infrastructure challenges. From the construction of entire data center buildings to the fabrication of advanced thermal management components, 3D printing is poised to reshape the industry in unprecedented ways.

Market Prospects and Exponential Growth

The intersection of additive manufacturing and the data center industry presents unparalleled opportunities. According to the latest research from Additive Manufacturing Research, the penetration of additive manufacturing technology within data center infrastructure is anticipated to experience a significant surge by 2033. This market is rapidly becoming one of the most compelling growth vectors for the additive manufacturing sector over the next decade.

Consider this: even under conservative market penetration estimates, the production of cold plates and other essential data center components could require as many as 2,000 powder bed fusion (PBF) machines by 2033. To put this into perspective, this figure surpasses the total annual sales of machines throughout the entire 3D printing market today. This forecast underscores the exponential growth potential that the 3D printing industry stands to gain within the data center market.

3D Printed Buildings and Rapid Deployment

The transformative power of 3D printing extends across the entire spectrum of data center development, from the construction of buildings to the fabrication of critical equipment. Imagine constructing data centers in mere weeks, rather than months or even years. This accelerated timeline is no longer a hypothetical concept.

The “Wave House” in Heidelberg, Germany, stands as a testament to this reality. As Europe’s first 3D-printed data center and the largest 3D-printed building on the continent, it was constructed using a single COBOD BOD2 printer. This machine, capable of printing 43 square feet per hour, completed the wall structure in just 140 hours, utilizing recyclable cement-like materials.

Compared to traditional construction methods, 3D printing dramatically reduces the construction cycle, enabling data centers to respond swiftly to escalating market demands.

Furthermore, 3D printing empowers developers to customize data center designs to meet specific needs and environmental conditions, resulting in structures that are not only more functional but also aesthetically appealing.

These 3D-printed buildings utilize fewer resources and generate less waste, contributing to enhanced energy efficiency and providing a more environmentally sustainable solution for data centers.

Advanced Thermal Management and Cooling Solutions

The challenge of thermal management in data centers is equally pressing. As server performance continues to escalate, so does the corresponding power consumption and heat generation. Traditional air-cooling methods are reaching their limits in handling high-power-density packages. This is where additive manufacturing steps in with advanced thermal management solutions.

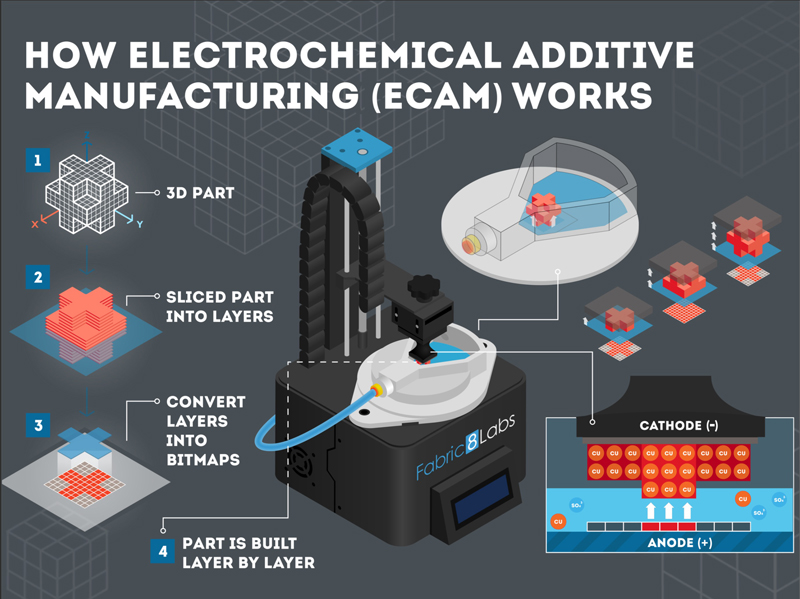

Electrochemical Additive Manufacturing (ECAM): Fabric8Labs’ ECAM technology offers a revolutionary breakthrough in data center cooling. It uses low-cost metal salts and a microelectrode array to build at the atomic level.

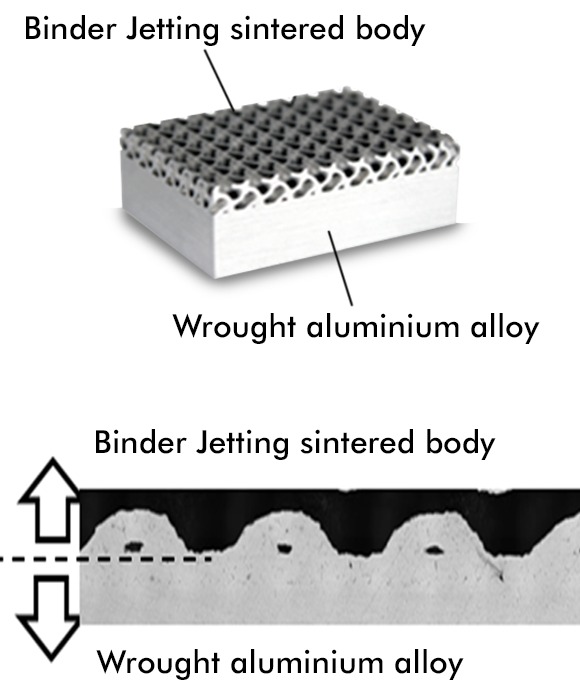

Binder Jet Technology (BJT): Ricoh’s innovative diffusion welding technology integrates efficient heat dissipation structures manufactured via BJT with traditional forged aluminum alloy shells or substrates.

Selective Laser Melting (SLM) / Laser Powder Bed Fusion (LPBF): This technology excels in manufacturing high-performance heat sinks with complex internal structures, using materials like AlSi10Mg and copper alloys.

TPMS Periodic Structures: 3D printing enables the creation of triply periodic minimal surfaces (TPMS) lattice structures for heat sinks, offering superior heat dissipation.

Industry Leaders and Strategic Positioning

Key players such as Alfa Laval, Asetek, and Conflux Technology, leaders in heat exchange, separation, and fluid handling, are actively exploring the use of 3D printing in manufacturing high-efficiency heat exchangers.

Data center infrastructure giants like Schneider Electric and Vertiv are also investigating the use of 3D printing in power and cooling systems.

Technology and cloud computing leaders, including OpenAI, Google, Meta, and Amazon, are recognizing the immense demand for efficient thermal solutions.

Partner with FacFox for Cutting-Edge 3D Printing Solutions

As the data center industry embraces the transformative potential of 3D printing, partnering with a reliable and experienced provider is crucial.

FacFox offers a comprehensive suite of 3D printing services, enabling you to bring your innovative data center designs to life. From rapid prototyping to large-scale production of complex components, FacFox’s advanced technologies and expert team ensure precision, quality, and efficiency.

Whether you’re exploring advanced thermal management solutions or seeking to revolutionize data center construction, FacFox is your trusted partner in the 3D-printed data center revolution.

Contact FacFox today to explore how we can help you achieve your infrastructure goals.