This guide is all about doing clever things in a software to get the best results out of a 3D printer. The main focus is turning intricate CAD files into a format that you can print without small details or thin walls being neglected by the slicer. Get amongst it if your keen, a 3D printer I am particular taken by the Ultimaker S5.

Quick links for the contents of this guide is seen below.

- The Situation

- Surface Mode

- Workflow to Create the Final Printable CAD Design

- Actual Printing

- Acknowledgment

This guide will focus on options within Cura but other slicers will have similar options. There is an Ultimaker Cura Overview for Makers Guide which is a great reference point if this is your first time encountering Cura and you want to hit the ground running. Cura is completely free software available online with a great track record, used by over a million users worldwide and handles around 1.4 million prints per week. Cura can also help expand your creativity and this is best demonstrated in the rundown of Exciting Features in Cura.

As always if you have any questions, queries or things to add please let us know your thoughts!

The Situation

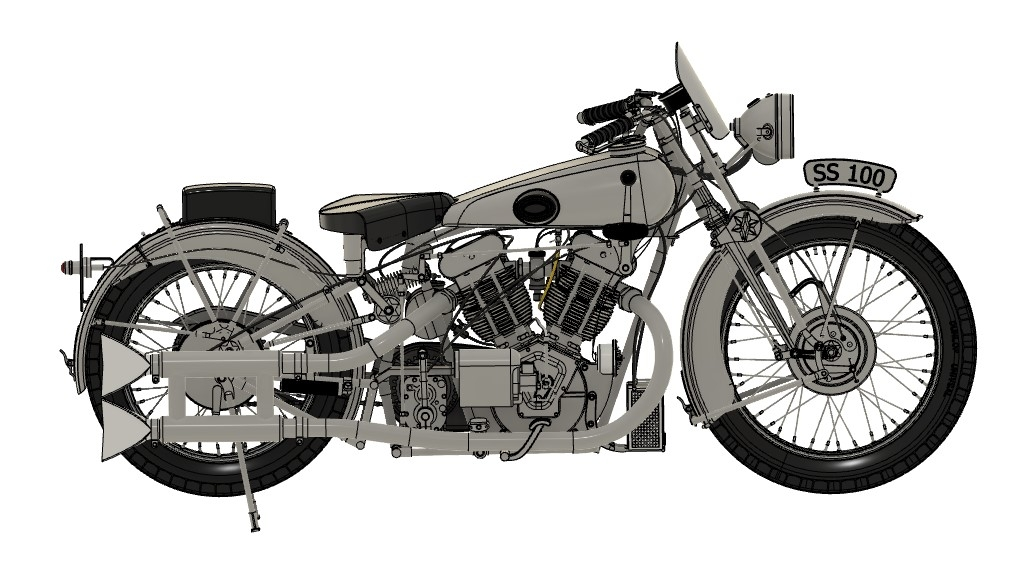

So sometimes you can get your mitts onto an unbelievable impressively detailed model scaled to the correct size like those coming out of Ukraine and Uzbekistan (the CAD designers over there are beyond impressive and that fact that they provide heaps of models for free is a true show of perfection). And you look at yourself and go, I wanna print that. See below for an image of a CAD representation of a Brough Superior SS100 (a bike that was built in 1924 and was capable of going over 160km/h) that made me feel this way.

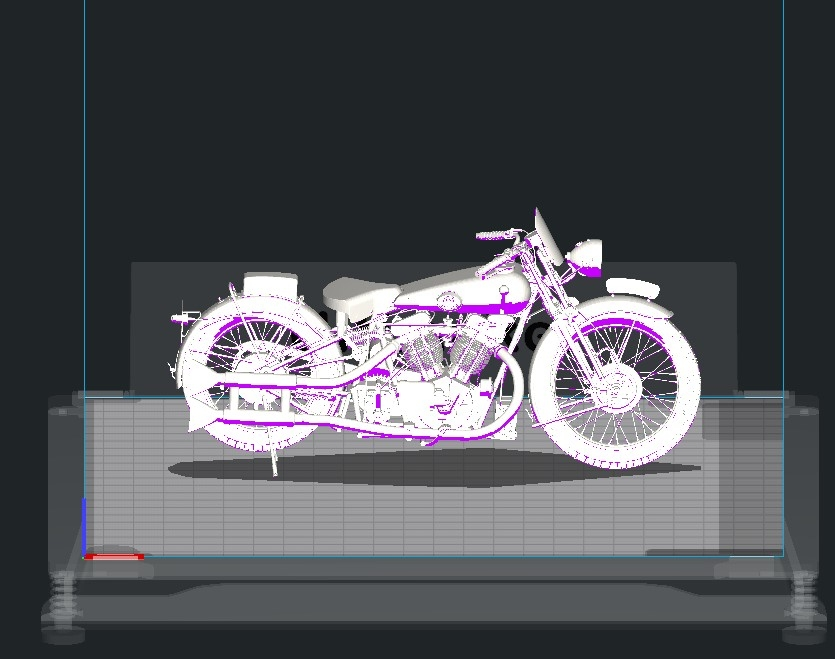

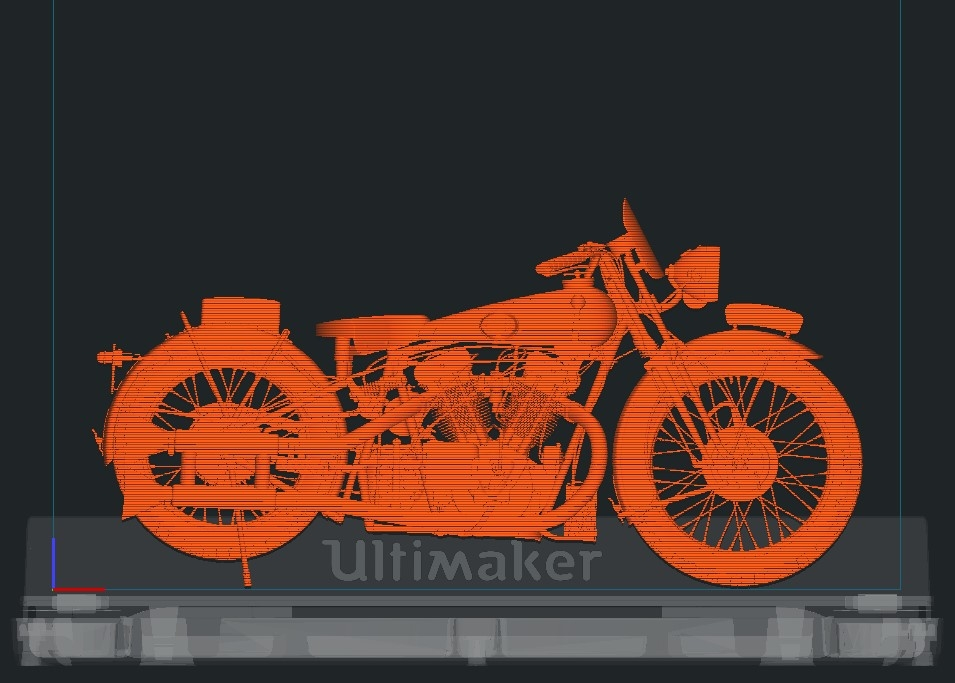

So you throw the model into your favourite cad program, export it out as an STL and throw the STL model into the Slicing program. Then because it is a full-sized model you end up having to scale it down and down to fit your build platform of choice. See below for the motorcycle model scaled so that it can fit on an Ultimaker print platform.

And you keep scaling down and scaling down until some of the walls end up very thin. Too thin for even extruder to accurately represent the model. What is really happening is that the walls of the model are too thin for the diameter hole of the extruder nozzle. As the nozzle is the limiting factor in regards to the thinness of an extruded material. Thus when you slice it large sections of the model are neglected as the slicers deems it impossible to replicate that section. See below for Cura not correctly slicing the exhaust, certain wire sections, the numberplates or the majority of the front light on the motorcycle because the walls are too thin.

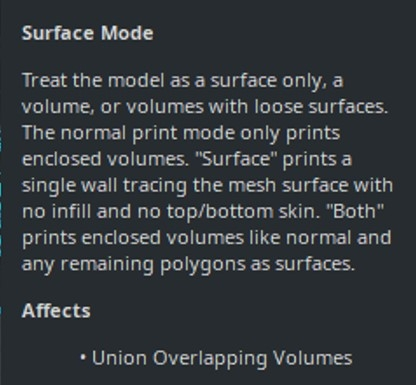

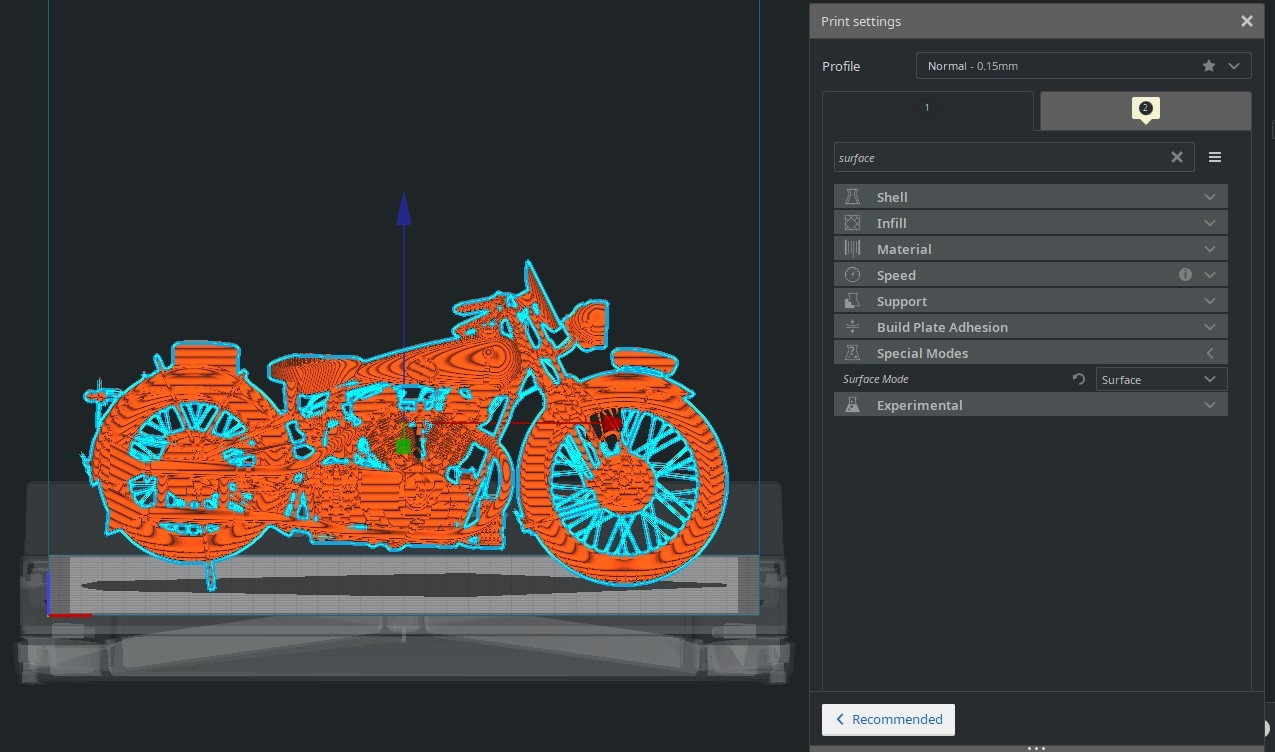

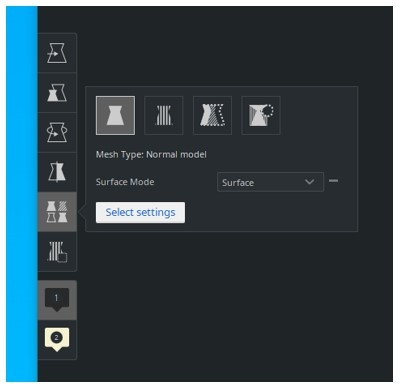

So what is the solution to this? The hardware side of it can be altered, running a smaller nozzle diameter to create thinner lengths of material can fix this issue. Then you can tell your slicer the new hardware and it will adjust accordingly. Or if you are interested mainly on the surface of the object being correct and the internals of the subject not necessarily requiring perfect dimensionality which is particularly applicable for most scale models (Side-note this is a very similar situation that the formidable Tamiya Company that make die pressed plastic model kits of all kinds of vehicles and aircraft, encounters all the time, although they use different techniques of manufacturing). Then the 3D printing Cura trick for you involves tinkering with Surface Mode and overlaying multiple versions of your subject. See below for a quick image on what surface mode does.

Surface Mode

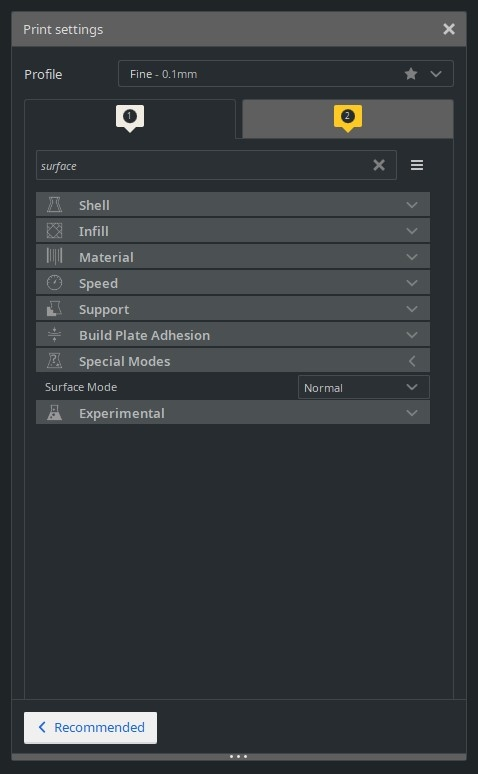

Surface mode is a special mode that allows the model to be printed as a surface only, a volume or volumes with loose surfaces. There are three settings available which correlate to these three options and they are – Normal, Surface and Both. See below an image as to where to find Surface Mode in the Advanced Print Settings.

If we were to make a scale model with Normal then we would lose the finer details. If we created a model with Surface then it would be completely hollow inside and be only a single wall thickness (with what is deemed the outside surface being perfectly dimensional correct). Now from personal experience, Both seems not to actually do both. Below you can see the effect of using | Surface Mode – Surface | on the Motorcycle model, note all the detail that has been captured for example the exhaust system and the front light that was not before.

Workflow to create the Final Printable CAD Design

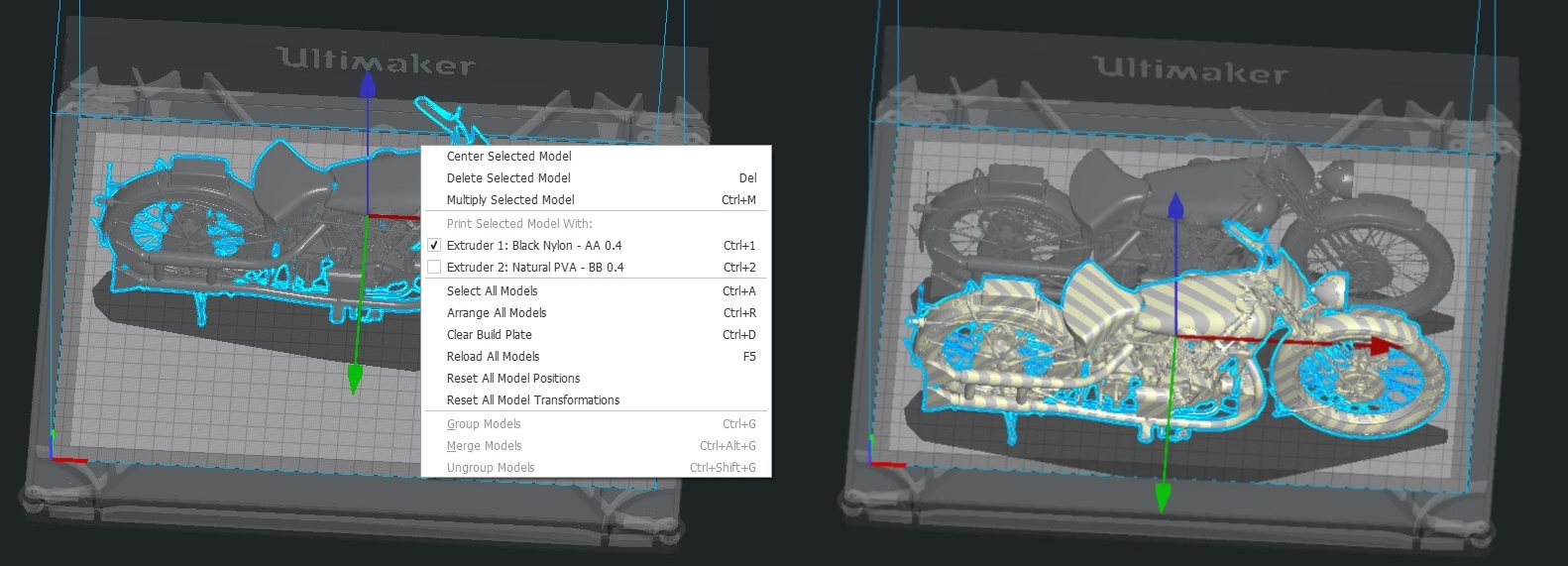

So, knowing all this to create a strong model with all the detail included the best method I have found to date is to start by importing two models into Cura of the subject. You can also multiply the model by right-clicking and selecting | Multiply Selected Model | as seen in the images below.

Then overlay both models perfectly on top of each other. This can be done in the menus on the right by setting all x, y, z location coordinates to the same. Also, make sure your model is scaled correctly. It is crucial that they sit on top of each other perfectly. See below for perfect laying over on the right and incorrect laying over on the left. When the models are overlayed perfectly correctly you sometimes get pretty blue stars all over the subject as you can see in the image below on the right.

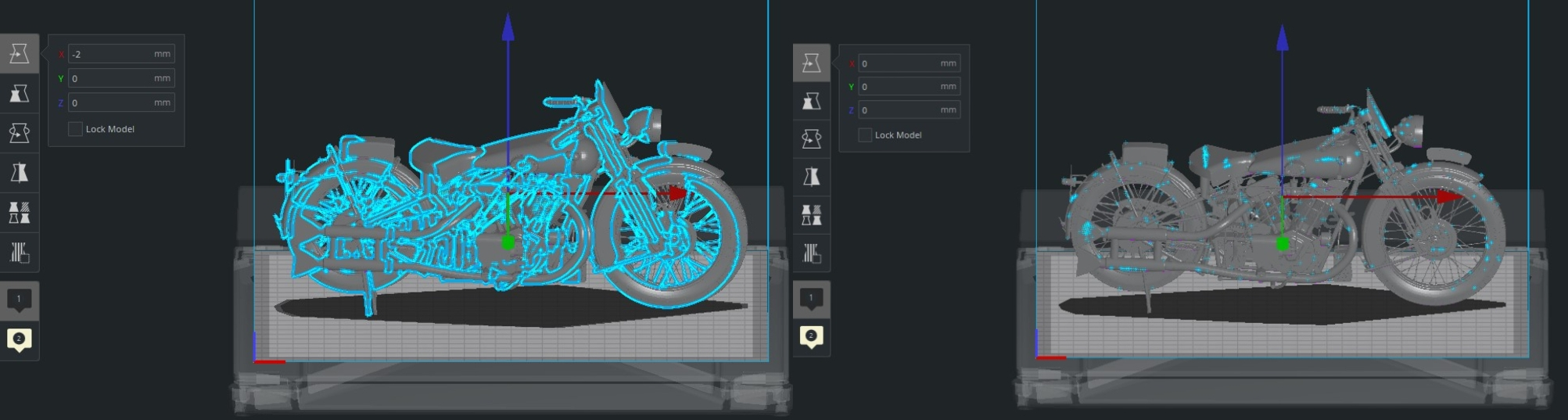

Now that the two CAD files are overlaid perfectly we can now adjust the Per Model settings which are found to the left of the screen. This toolbar lets you adjust the settings for each unique model you have on the build plate. Check out Ultimaker Cura – An Overview for Makers if you need a quick way to get up to speed. Then click on one of the models and the models using the per model setting option to have a | Surface Mode – Surface | as you can see the image below. Then keep the default Surface Mode settings for the other CAD file.

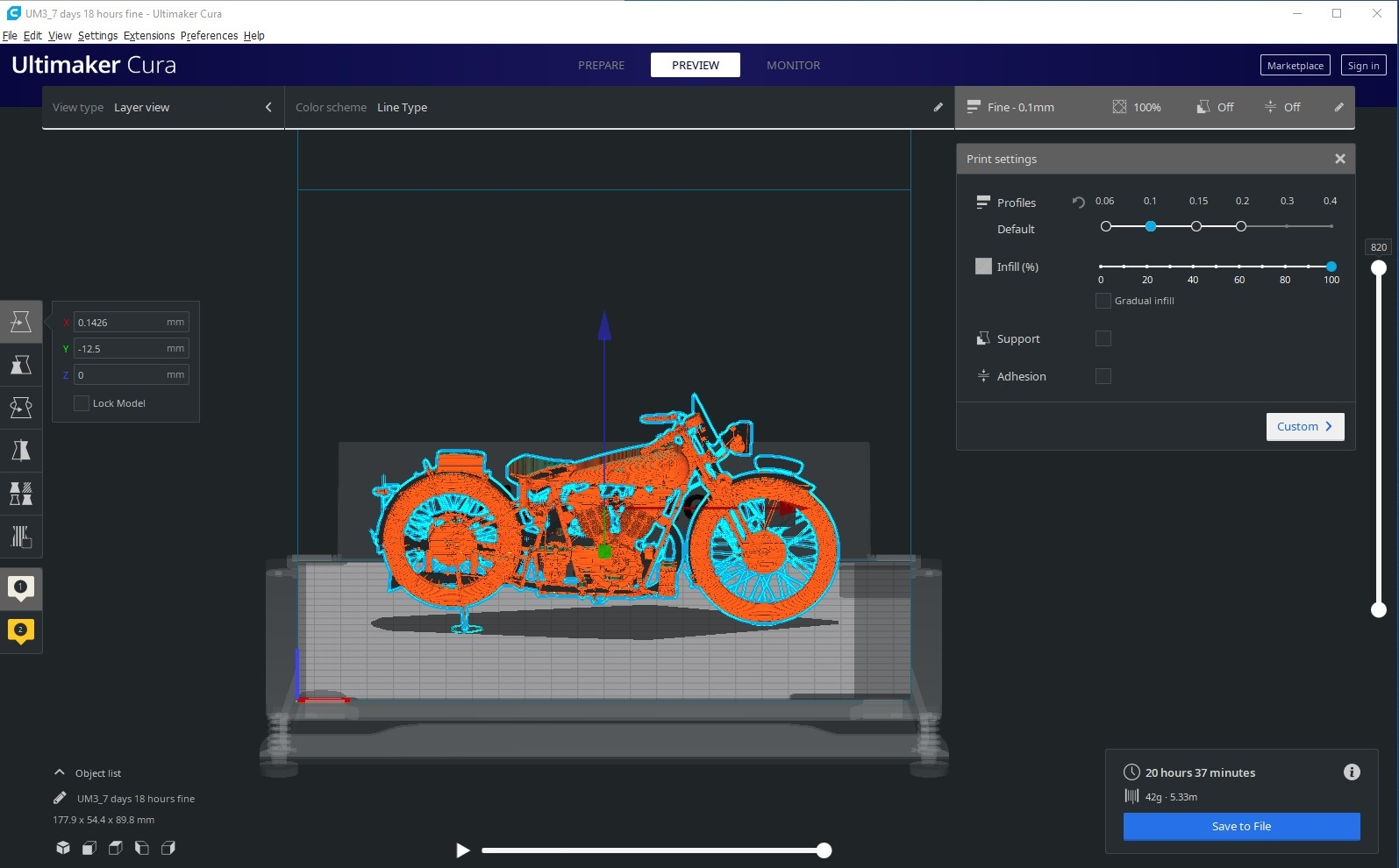

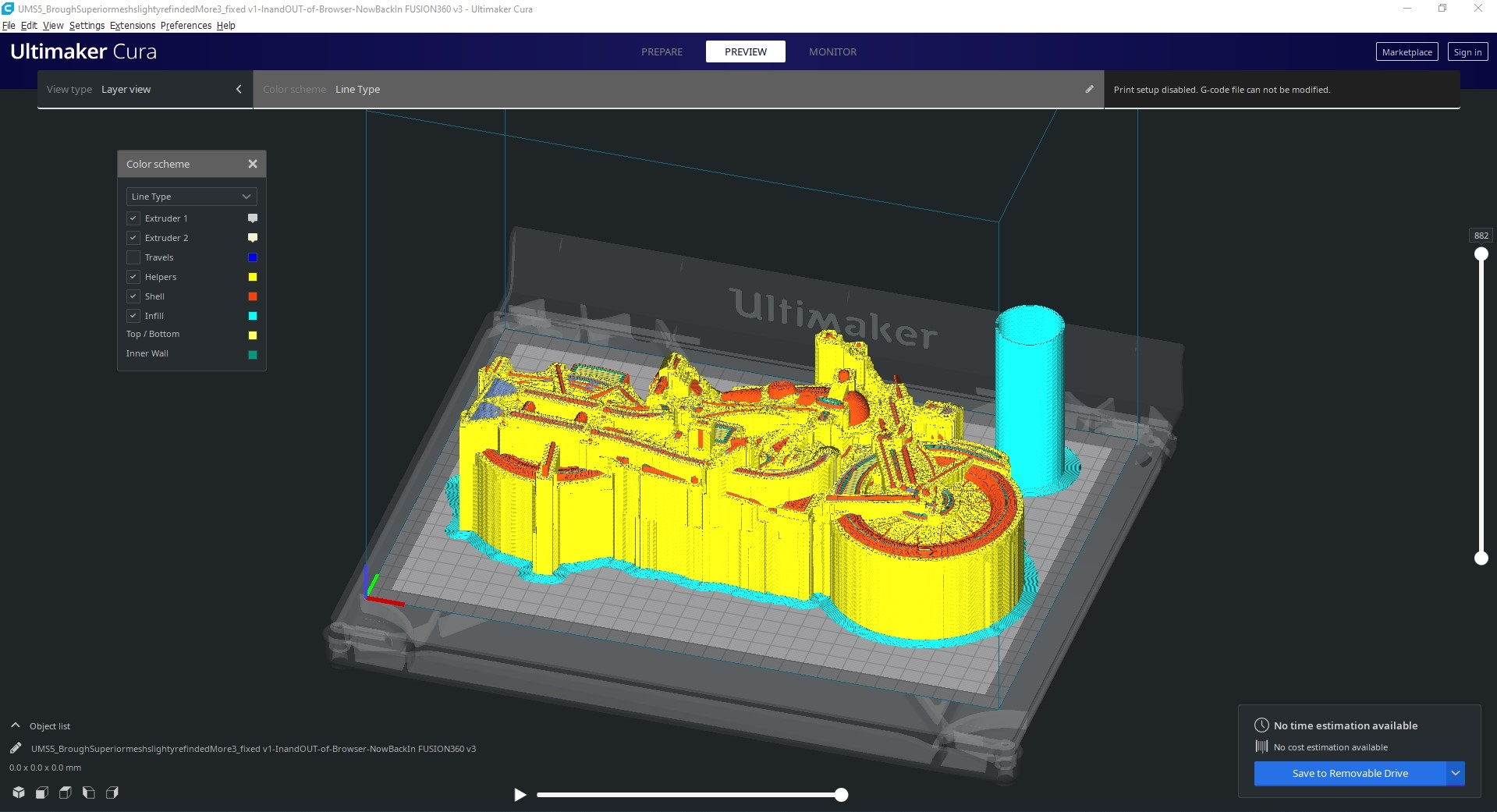

Thus once you press slice, you will now have a sliced CAD file made up of one of the models in surface mode and the other model set in normal mode. This results in a print which is both externally dimensionally correct and has enough strength to survive the real world. Check out below for the sliced CAD image of both models when stacked perfectly and sliced with different Surface Mode Settings to complement each other.

Actual Printing

This guide focused on expanding the print potential of CAD files. In doing so increases the availability of ready-made free CAD models which you can create real objects from. When it came to actually printing this motorcycle, it was laid down on the side and a large amount of support material was used. You can see an image of the sliced CAD file below set up in Cura which I used to 3D print this motorcycle.

I used CPE transparent as the material for its strength properties however it is also a material prone to stringing. There is always finesse in fine-tuning a 3D printing for new material and have a way to go with the CPE transparent material. Below you can see the steps I took in this printing process. Dissolving the PVA was a particularly magical moment.

Also, I experimented with not using an ooze shield (as I considered the PVA support would take over the role of that job) however the lack of protection affected the result of the handlebars and footrests. Both required post-processing to repair. If you want to learn more about ways to improve dual extrusion prints check the guide Ooze Shields and Purge Towers.

But hopefully, this demonstrates to you how close we are to FDM printing large scale models. The “Press play, wait and there it is! (ripe and ready for some paint)” is just so close. In fact, the limiting factor is me, great 3D printing gods I beg of you just let me 3D print better. I have attached below is the exact Cura CAD files that I used to print this motorcycle. Check out that file naming for a smile.

Acknowledgement

Big thanks goes to Komil Arzykulov and the GrabCAD community. Excellent 3D modeller from the Uzbekistan which has the greatest (and free) CAD models of motorcycles available online. The amount of painstaking work that has gone into his models are truly something worth celebrating. Cheers mate. Attached below are the Cura files for the motorcycle model I printed here. Find his amazing work here. Also a hint in the image below on how long it took to print this amazing machine.

Source: Core Electronics

https://core-electronics.com.au/guides/print-scale-model-detail/