Additive manufacturing has transformed the jewelry-making process. So which is the best 3D printer for jewelry? Find out!

Jewelry Has Gone Digital

Traditional jewelry-making is a detailed and time-consuming process. Nobody can deny the skill and craftsmanship that goes into a handmade ring or pendant, and there will always be something unique about manually sculpted personal adornments. Still, the fact stands that it takes a lot of time and patience to make jewelry completely by hand.

Many jewelers and goldsmiths have woken up to this reality and started looking for solutions to make jewelry production easier. Additive manufacturing and 3D printing have stepped in to help them.

And when we say “many goldsmiths,” we mean it — the jewelry 3D printing segment is estimated to be worth $5.5 billion by 2026. Like so many other things, jewelry has gone digital.

The Advantages of Jewelry 3D Printing

It’s important to note that when we talk about jewelry 3D printing, we don’t mean directly printing jewelry in precious metals. Although this is definitely possible — and the technology to do so is advancing rapidly — most jewelers don’t use 3D printers this way, as the tech is not quite accessible in terms of price.

Instead, jewelers use 3D printers to print out master or wax models and patterns to use in combination with traditional lost wax casting. The lost wax method, if you’re not familiar, is where a wax model is encased in a plaster-like medium that hardens and is then heated so the wax model melts away leaving a mold that’s then filled with molten precious metal.

So instead of hand carving wax the traditional way, jewelers today 3D print in wax. A 3D printer makes it possible to create a finely detailed, master wax model.

Of course, to 3D print your wax model, you have to start with a digital file of the jewelry piece itself. Where traditional jewelry makers may start with a sketch on paper, digital jewelers create their designs in 3D using computer aided design (CAD) software, such as Mudbox, RhinoGold Basic, and SketchUp.

The Advantages of Jewelry 3D Printing

It’s important to note that when we talk about jewelry 3D printing, we don’t mean directly printing jewelry in precious metals. Although this is definitely possible — and the technology to do so is advancing rapidly — most jewelers don’t use 3D printers this way, as the tech is not quite accessible in terms of price.

Instead, jewelers use 3D printers to print out master or wax models and patterns to use in combination with traditional lost wax casting. The lost wax method, if you’re not familiar, is where a wax model is encased in a plaster-like medium that hardens and is then heated so the wax model melts away leaving a mold that’s then filled with molten precious metal.

So instead of hand carving wax the traditional way, jewelers today 3D print in wax. A 3D printer makes it possible to create a finely detailed, master wax model.

Of course, to 3D print your wax model, you have to start with a digital file of the jewelry piece itself. Where traditional jewelry makers may start with a sketch on paper, digital jewelers create their designs in 3D using computer-aided design (CAD) software, such as Mudbox, RhinoGold Basic, and SketchUp.

What to Look For

The first consideration when choosing a jewelry 3D printer is the technology. This, however, is an easy choice. Most jewelers opt for resin-based SLA or DLP printers due to their high printing resolution and the availability of wax resins that will burn out cleanly during casting. If you’re not familiar with resin-based SLA or DLP 3D printing technology, check our our guide here:

There are some filament-based FDM printers that can print using wax filaments. However, as most FDM printers can’t create sufficiently fine details for intricate jewelry, it’s best to look for a resin printer. Though we have to hand it to FDM printers, they are usually faster.

Other considerations when picking your printer are:

- Resolution: Pieces of jewelry are small, and so the finer the detail your printer can produce, the better. You should aim for a machine that is able to create the finest possible details, ideally even as small as 10 microns.

- Print Speed: It’s hard to imagine a case where hand carving wax would be faster than 3D printing it, so when it comes to speed, we’re talking among 3D printers. Ideally, look for a machine that lets you adjust the speed to get super-fast but less detailed prototypes as well as extremely fine details, which typically take a bit longer.

- Material Compatibility: Opt for a printer that is not limited to one manufacturer’s materials. It might just be that the best wax resin for your purposes is made by a third party. Proprietary materials are also often much more expensive than third-party ones.

- Cost: When purchasing a printer, you need to not only consider the printer’s price, but also the cost of maintenance and materials. Although a jewelry 3D printer can return your investment in a few months, it’s good to pay attention to the budget.

- Exposure: If your designs have fine features and smooth surfaces, you’ll want to be careful with LCD technology. Some LCD machines produce models with a pixelated surface, and this could translate to the final piece when cast, unless you take time to do some post-processing.

No matter how good a printer sounds on paper, you can’t replace practical experience. If you want to evaluate a printer’s suitability for your workbench, you can ask the manufacturer for a sample print. Most will be happy to demonstrate the capabilities of their printers in practice.

Our Top Picks & Listing Criteria

For this list, we’ve considered the capabilities and cost of each printer and split them into three categories: budget, mid-range, and professional. Although our process has been by no means scientifically rigorous, it will give an idea of the printers’ features. Also, keep in mind that some of these top manufacturers offer both budget and production printers.

We’ll start with the budget category, which are great machines if you’re new to 3D printing and want to learn the ropes. You can get a really good resin printer, like the Elegoo Mars 2, for about $200 to get your feet wet in the technology, but it may not have the super fine resolution some jewelry makers are looking for. Several of our top picks for budget resin printers in our guide linked below are great for jewelry, but jewelry-specific 3D printers offer just a bit more in the way of features and support.

As you can see, there are hundreds of resin printers on the market, below are our top pics for quality machines that won’t disappoint.

The second category features mid-range printers that offer a wider range of features while still coming with a reasonable price tag. Finally, we’ll cover professional production printers that are more expensive, but are fully capable of scaled-up jewelry production. Some of these pro printers have the capacity of printing dozens of models at once and churning out thousands a week. Just like in the world of budget resin printers, there are great resin printers in the professional and industrial category that don’t necessarily focus on jewelry, but may fit your needs. Check out our guide to professional resin printers below.

Creality 3D Halot-Max

Chinese 3D printer maker Creality 3D, founded in 2014, has won several awards, even from us at All3DP. Their Halot-Max SLA resin printer continues their tradition of providing highly functional machines at an affordable price.

Housed in a sturdy sheet metal shell, the high-precision Halot-Max can print details as small as 10 microns at a speed of 1-4 seconds per layer. Although it is an LCD printer, the company claims its 300W integral light source removes the problem with pixelated surfaces.

One of Halot-Max’s main selling points is its AI-driven “brain,” powered by an ARM Cortex A53 processor. This brain gives the printer high data and image processing capabilities, and operates its stable printing mechanism with an intelligent braking system.

According to the manufacturer, Halot-Max supports third-party resins, making it a suitable printer for wax resins. With a 2,000-hour lifespan, the Halot-Max is a good starting point for new jewelry 3D printer operators.

- Technology: SLA

- Build Volume: 293 x 165 x 300 mm

- Material Compatibility: Creality and third-party resins

- Price: $949

Peopoly Phenom

California-based Peopoly replaced its earlier Moai printer line with the Phenom in early 2021. The new Phenom does away with the laser-based technology of its predecessor in favor of an LCD + LED approach.

This technology cures an entire layer of resin at once, giving the Phenom fast print speeds and making it suitable for producing several jewelry molds at once in its large print chamber. The downside is that the intense light damages the internal parts just as fast, and the manufacturer promises the LCD panel only a 400-hour lifespan.

Nonetheless, Phenom is capable of good print surface qualities with a 72-micron resolution. Thanks to the well-sized print chamber and lighting technology, it enables borderline mass production of jewelry molds at a high speed.

The Phenom is more than twice the price of Creality Halot-Max, so it will strain your budget a bit more. However, at that price, you get a slightly larger print volume and impressive performance — not too bad of an exchange.

- Technology: MSLA

- Build volume: 276 x 155 x 400 mm

- Resin compatibility: Peopoly Deft and third-party resins

- Price: $1,999

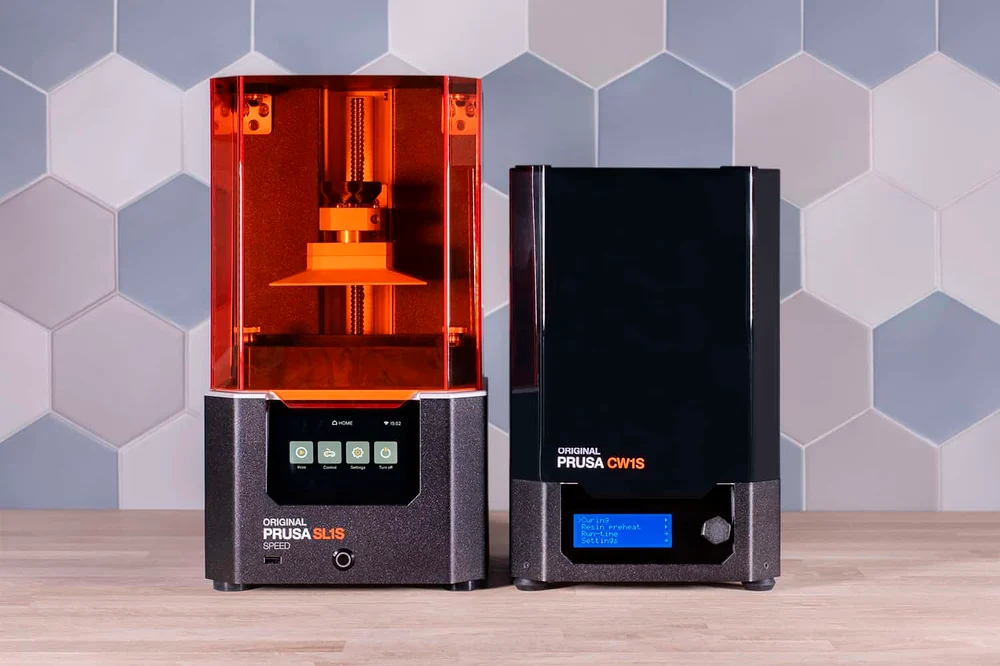

Prusa SL1S Speed

This entry was supposed to be for the Prusa SL1 printer. Then the Czech company suddenly released the updated SL1S Speed model in June 2021 and left us scrambling to update our list.

True to its name, the name of the game with the new Prusa is speed. The SL1S is capable of delivering a print speed of 1.4 seconds per layer at a high resolution. It can produce details as small as 10 micros (the recommended resolution is 25 microns).

The printer features a quick-release platform that retains its calibration, and supports swappable resin tanks. It also has a new 5.96” monochrome LCD panel that provides better print quality and a reworked UV LED optics panel for faster printing.

The SL1S is held back by its print chamber size, which is significantly smaller than that of the other two budget printers (despite being 25% bigger than the SL1’s). However, out of all the budget printer manufacturers, Prusa is the only one to provide its own wax casting resins. The printer also supports third-party resins.

Prusa also offers its own curing and washing unit to post-process your prints. If you feel the need for speed and large print volumes aren’t that important to you, you should definitely give the Prusa SL1S Speed a chance.

- Technology: MSLA

- Build Volume: 127 × 80 × 150 mm

- Material Compatibility: Prusa and third-party resins

- Price: Prusa SL1S Speed $1,999; Prusa post-processing unit $749 or $599 if bundled with the printer

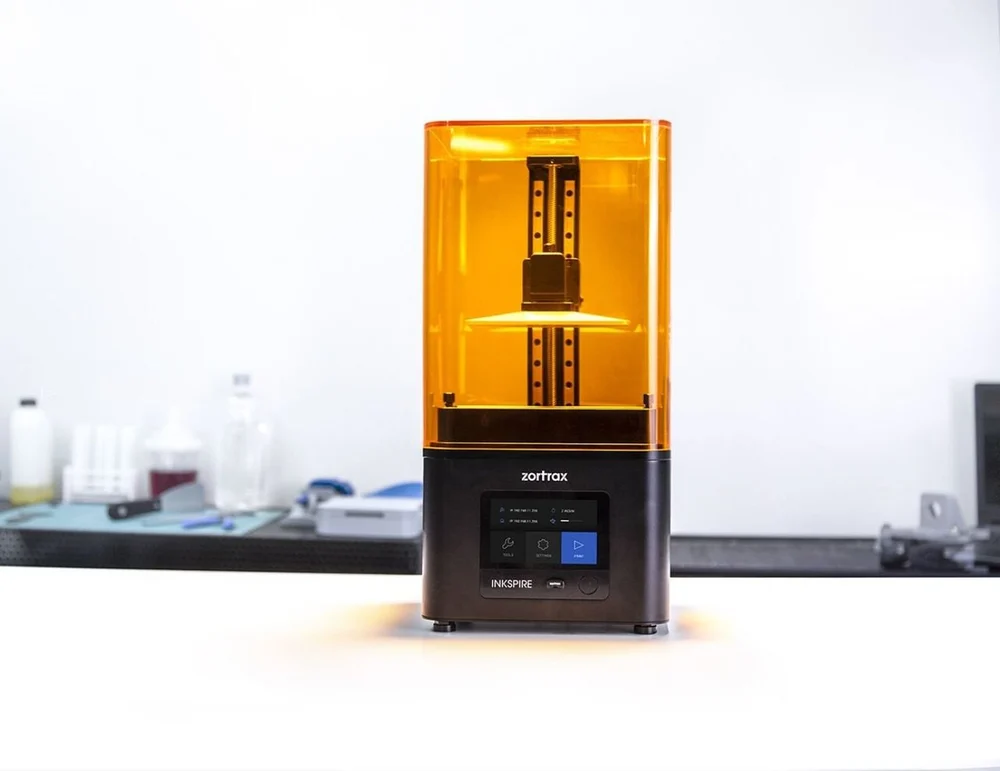

Zortrax Inkspire

Poland’s Zortrax, founded in 2011, provides this list’s most affordable mid-range printer with the Inkspire. The printer’s UV LCD technology offers consistent print speeds no matter how much of the printing surface is used, making it a good option for printing multiple master or wax models at once.

The Inkspire has a minimum layer height of 25 microns, which is on par with many other listed machines. The printer is easy to use thanks to its automatic calibration and Android-based operating system.

The more affordable price of the Inkspire means that the print chamber is on the smaller side. Additionally, the manufacturer promises only a 200-hour lifespan for the LCD screen before it needs to be replaced.

Nonetheless, the Inkspire is a capable machine that can produce repeatable, consistent prints with a high surface quality. It can also expose supports to the UV light for a longer time, hardening them and making them easier to remove.

Zortrax offers its own BlueCast range of castable resins, but the Inkspire also supports any light-curable resins, so you’re spoiled for materials options. The company also manufactures an ultrasonic cleaner unit.

- Technology: UV LCD

- Build Volume: 132 x 74 x 175 mm

- Material Compatibility: Zortrax BlueCast and third-party resins

- Price: $2,299

Formlabs Form 3

Formlabs, founded in 2011 in Massachusetts, is one of the biggest names in reasonably priced SLA and SLS printing. Similarly, their form series — including its latest reincarnation, the Form 3 — is one of the best-known SLA printers.

With the Form 3, Formlabs introduced a revised light processing unit, which makes it possible to print faster and with greater precision — up to 25 microns. Compared to Form 2, the Z-axis on the Form 3 has gained another 10 mm. This is handy because it means build plates from the Form 2 can be used with the Form 3.

Like Prusa and Solidscape, Formlabs offers its own range of castable wax resins, which the company says are optimized for zero ash content and clean burnout. Form 3’s high accuracy also makes it suitable for master pattern printing.

Formlabs also offers its own washing and curing stations. If you buy all three machines, you’ll have to dig deeper into your pockets, but you will also a get a full 3D printing stations with a proven good reputation.

- Technology: Low-force stereolithography (LFS)

- Build Volume: 145 x 145 x 185 mm

- Material Compatibility: Formlabs resins

- Price: Form 3 $3,499; Form Wash $499; Form Cure $699

DWS 029JL2

DWS Systems is an Italian company that produces a line high-quality industrial 3D printers for jewelry. The smallest of which is the XFAB 2500HD, which is ideal for professional applications in jewelry to produce models for direct casting and rubber moulding.

All DWS printers use the company’s proprietary software Nauta+, that enables you to modify supports, alter the orientation and the position of objects for best 3D printing, as in maximizing the quality of surfaces. The printer features also the Fictor software, that allows to manually customize the parameters of DWS materials based on the user’s know-how. Resolution is is a nice 10 – 100 microns.

The smart cartridges for the XFAB series have been designed to eliminate the often messy liquid resin issue, ensure safety, a quick material change.

If you’ve got a serious jewelry operation, we’d surely recommend looking into this printer.

- Technology: SLA

- Build volume: 180 x 180 x 180 mm

- Resin compatibility: DWS resins

- Price: $7.000

Solidscape S325 & S325+

Solidscape, founded in 1994, is now a subsidiary of 3D printing giant Prodways. Their S325 and S325+ wax resin printers use the company’s proprietary Smooth Curvature Printing (SCP) technology, and are tailor-made for jewelry wax 3D printing.

The S325 is the high-precision sibling of the duo, with a minimum layer height of 25 microns. The S325+, on the other hand, is the speed demon, exchanging some detail for a higher print speed to enable easier mass production.

The machines work with Solidscape’s proprietary Midas wax resin, which is a high-performance material developed especially for direct casting in precious metals. The printer duo also autogenerates supports for the prints using the company’s Melt material, which dissolves upon print completion.

Both the S325 and the S325+ are fully automated, with a reasonably sized printing chamber. These specialist tools of course come at a specialist price point, but you’ll get a printer that’s custom-built for jewelry-making.

- Technology: SCP

- Build Volume: 152 × 152 × 101 mm

- Material Compatibility: Solidscape Midas wax resin

- Price: $10,000

3DSystems Figure 4 Jewelry

3D Systems produces a whole range of 3D printers for jewelry casting, including the ProJet MJP 2500W and 3600W and the ProJet 6000 HD. The Figure 4 Jewelry is geared towards printing both casting and master models.

It can achieve high print speeds, up to 15 mm per hour when printing at a resolution of 30 microns. 3D Systems has available a proprietary casting pattern material, in addition to a material made specifically for printing master patterns for molding.

The Figure 4 Jewelry uses non-contact membrane technology, which work together with the company’s exclusive MicroPoint supports to reduce part-to-support contact to a minimum. The technology produces smooth walls and high-detail patterns that require little post-processing.

The printer brings to the table fast production speeds for casting and master patterns, alongside prototypes and fit check models. 3D Systems also offers a UV post-curing unit (required for finishing prints) and a mixer for printing materials.

- Technology: DLP

- Build volume: 124.8 x 70.2 x 196 mm

- Resin compatibility: 3DSystems and third-party resins

- Price: $12,000

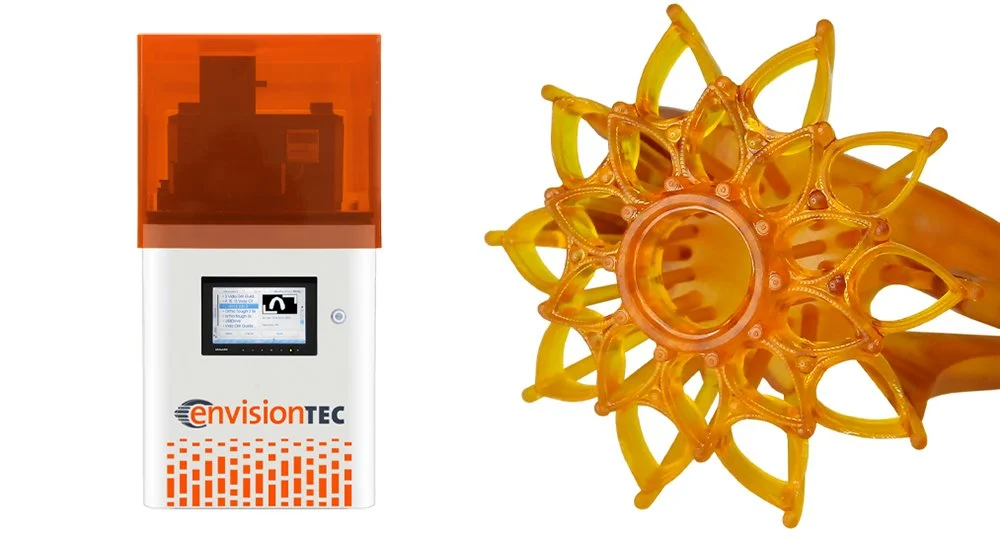

EnvisionTEC Vida cDLM

The name of EnvisionTEC’s Vida UHD cDLM printer is a mouthful, but it makes more sense when you consider that it’s part of the company’s Vida printer family. The family also includes the Vida and Vida HD printers, but the Vida UHD cDLM is the highest-precision sibling. EnvisionTEC was purchased by 3D printer manufacturer Digital Metal in 2021.

The machine achieves resolutions as precise as 15 microns with EnvisionTEC’s proprietary CDLM printing technology. This printing methods allows for fast printing speeds while also reducing the need for supports, meaning less post-processing is necessary.

The Vida UHD cDLM has the smallest print chamber out of any machine on this list, which limits its potential for printing several models simultaneously. It’s also restricted to EnvisionTEC’s own castable materials.

Despite its limitations, the EnvisionTEC Vida UHK cDLM is a fast and precise printer that’s capable of accurate and high-quality surface finished. The company has more than 15 years of experience in the 3D printing space, so they will provide you with a quality printer.

- Technology: Continuous Digital Light Manufacturing (CDLM)

- Build Volume: 63.3 x 35.6 x 100 mm

- Material Compatibility: EnvisionTEC wax materials

- Price: $49,995

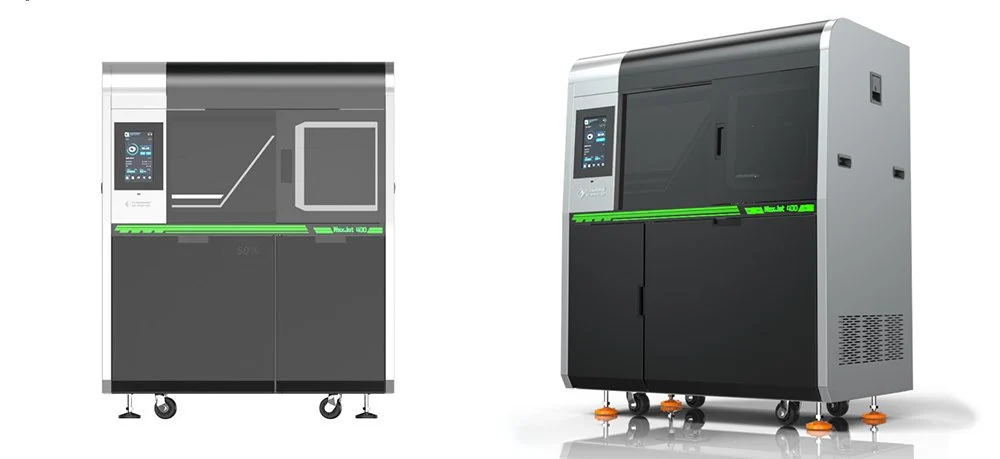

Flashforge WaxJet 400

Unlike other listed printers, the Flashforge WaxJet 400 uses the Multijet Printing (MJP) technology, which is faster than most SLA printers. This technology allows the WaxJet 400 to print with Flashforge’s 100% pure wax material at a minimum layer height of 16 microns, resulting in highly detailed ready-to-cast wax models.

This industrial-level printer is optimized for fast mass production. With its large print chamber, the manufacturer claims WaxJet 400 can produce up to 350 ring-sized models per day.

The printer also uses a dissolvable wax support material that makes post-processing faster and easier. If the WaxJet 400 seems like overkill for your purposes, Flashforge also offers the resin-based Hunter printer, alongside castable resin materials.

But the most important aspect of production printers is efficiency, and that’s where the WaxJet 400 shines. Flashforge delivers a jewelry-optimized, high-precision printer that every professional jeweler should consider.

- Technology: Multijet Printing (MJP)

- Build Volume: 289 x 218 x 150 mm

- Material Compatibility: Flashforge FFWJ1100 100% wax

- Price: $52,000

Get Your Jewelry Printed

If you’re not ready to dive into purchasing your own printer for jewelry, there are plenty of third-party printing services where you can upload your digital file, choose your materials, and receive your model in the mail. Some will also do the metal casting step for you – along with polishing and finishing – so you receive your final jewelry piece in the mail in precious metals, including gold, silver, and platinum. As we mentioned above, if you want a piece of jewelry directly 3D printed in precious metal – which isn’t common – be sure to ask the providers below if they offer that service.

FacFox. We offer a wide range of 3D printing services and materials and support worldwide shipment.

- Castable Wax

- Castable Wax Ultra HD

- Gold

- Platinum

- Silver

- Bronze

- Copper

- Brass

Craftcloud. All3DP’s platform also has a lot of materials.

- Castable Wax

- Gold

- Sterling Silver

- Platinum

- Bronze

- Copper

Sculpteo. This 3D printing provider also offers lost-wax casting to provide you with a was model or the final casting.

- Silver

- Bronze

- Brass

Shapeways. In addition to lost-wax casting, this service provider also offers a host of design guidelines for what exactly can be 3D printed.

- Gold (yellow, rose, white)

- Bronze

- Copper

- Platinum

- Silver