Model building has greatly helped architects represent their projects. By holding something in your hand, you can instantly get a better idea of the way a decorative feature or intricate element would look on a building when compared with a static 2D drawing.

The traditional method of creating an architecture model is cutting and gluing all the pieces made of cardboard, wood or other moldable materials. You need to prepare rulers, pens, cutting tools, cutting mats, glues, and board materials. The tools like X-acto knives and glue guns are quite dangerous and much carefulness is needed during the model making process.

With the help of 3D printing technology, many traditional time-consuming and labor-intensive industries have gone through a revolution, not to say the model making process. No more worry about safeness, pollution, or waste of materials.

Building cost-effective architectural models

The 3D printers can save the costs up to 75% and provide a model with high resolution. You can save the cost by cutting down labor costs, and decreasing material waste by over 90%. The cost-saving effect is more obvious when you producing multiple copies.

Saving time by 3D printing scale models

The traditional method of modeling can take several weeks while 3D printing only needs a couple of hours making the same or better one. You just need to input the 3D file and wait for the printers to work, they can operate overnight and needs no rest. Besides accelerating the design process, it eases a lot of burden on human beings, right?

Easily updating architectural 3D models

The revisions during the design and communication process are inevitable, and the 3D printing technique offers you maximum flexibility. You can edit the 3D file and reprint one as long as your client changes his mind. It’s quite useful when you make a mistake related to the volume or structure. Additionally, this technology will encourage you to generate bolder and fancier ideas.

3D printing accurate and vivid architectural models

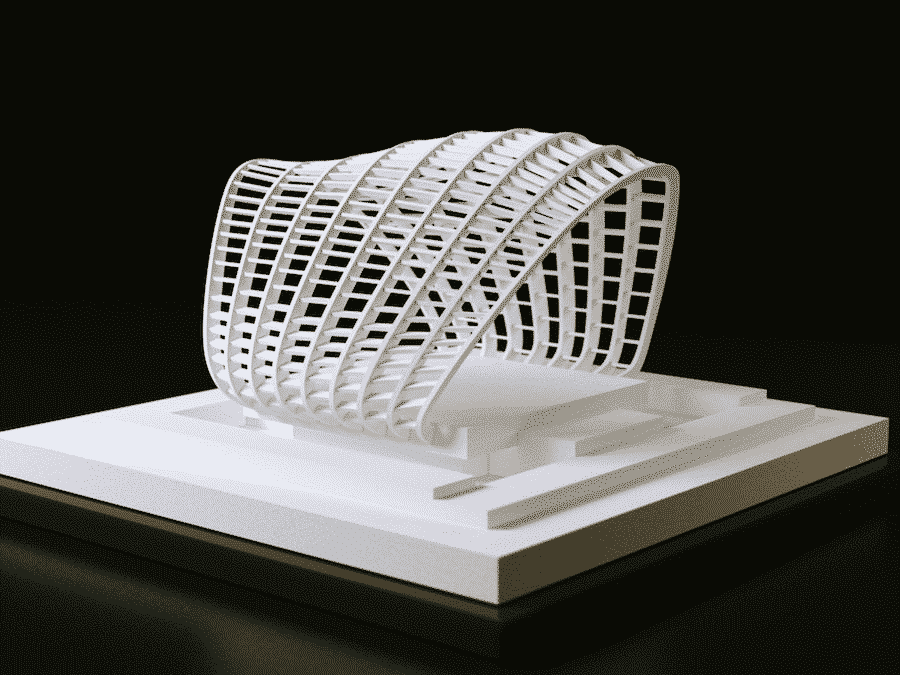

To leave your customers a strong impression, an accurate and vivid 3D printed model is never the wrong choice. With the help of 3D printing, you can fully give the rein to imagination, creating intricate and elaborate models that cannot be created by any other method.

Nowadays you’re enabled to use hundreds of materials to make a perfect model, no only the most common material PLA, ABS, photopolymer, and Nylon, but also metal and sandstone. A lot of finishes can also add aesthetic value to your model.

Model Requirements

Architectures should meet the basic requirements of 3D printing technology for closed solid files, and please also note the following adjustments to the model:

Before completing the modeling work and start printing the model, it is necessary to adjust the detailed component size, model decomposition, and model grouping of the model according to the performance of the 3D printer equipment and the choice of printing materials to ensure the realization of the end-use requirements. Due to different 3D printing molding technologies and 3D printing materials, there are minimum wall thickness and subsequent cleaning or removal of support requirements. If the wall thickness is too small, the components are easily damaged during the cleaning process.

- Adjust the model facade Sometimes the model to be printed exceeds the size of the 3D printer, and the model must reflect the architectural details. If the model print size is too small, many details will not be presented effectively. According to subsequent use, the model needs to be decomposed. You can realize the final model printing effect by printing different stocks. During segmentation, selecting a part of the facade with vertical or horizontal lines will be a good choice, so that subsequent stitching seams will not affect the overall effect of the model. To save the material cost, the model facade is usually printed very thin. To ensure the model is assembled tightly and integrally, you need to design a joint component incase the model deformation.

- Process the model details When the size of the architectural model is shrunk by at least dozens of hundreds of times, Some details (eg. outer details such as columns, window frames, glass walls, railings, etc) will become very thin and weak. It is impossible to remove the supports or clean the powder. Therefore, some details of the model should be appropriately enlarged and adjusted according to the minimum wall thickness size and diameter requirements in order to meet the requirements of subsequent printing and cleaning.

- Interior model adjustment The adjustment method of the size of the interior model components is basically the same as that of the facade model structure. All of them need to meet the requirements that the calculated size of the components is reduced in proportion to the minimum wall thickness of the printer. In order to facilitate powder cleaning or support removal, the vertical and horizontal components of the interior model should be divided before printing. If those components need to be colored, they should also be split according to the color block and the coloring operation space.

- Simplify the internal structure Try to delete the irrelevant display components (such as furniture and some accessories, etc.) without affecting the force structure, appearance, and some essential details, which can save costs and improve 3D printing effectiveness.

Summary

We’ve all seen building models at sales offices. The traditional model building method is a delicate, time-consuming and laborious task, and often the perfect model effect is not achieved.

Now with the rapid development of 3D printing technology, we can reduce the manpower and time required, create detailed and accurate scale models, and effectively convey the unique concept of each design to the client. Reproduce accurate and detailed design elements in a short period of time is attainable, and the overall printing cost is much attractive compared to the cost of hand-made models. Composed of sturdy, durable material, the model’s wall thickness can reach 0.6mm and intricate details are unexpectedly strong.

The beauty of 3D printing is: You don’t even have to own a 3D printer to get to a great architecture model – you can always resort to 3D printing services. Facfox is always here to help:)