Plastic Injection Molding

With over 15 years of plastic injection molding experience, FacFox has grown to be recognized as a global leader in custom plastic injection molding. Partnering with OEMs worldwide, in a wide range of industries, we can design and mold custom plastic parts and assemblies that enhance end products, reduce overall part and production costs, and streamline assembly and manufacturing processes.

FacFox believes our true success comes only from an approach and commitment to plastic injection molding that provides each customer unparalleled competitive advantage in terms of improved quality, appeal, efficiencies and increased profitability.

Engineering Success

Our success is determined by our ability to maximize your success – and we know for injection molded plastics, the engineering and design development process is critical to achieving that success!

We have found the two most critical factors for success in the engineering and design development process are partnering with you early on in the design phase – and focusing on what we consider the 5 Keys to Success for engineering out cost and engineering in quality and optimal performance. To achieve success, all five of these stages must work together.

- Part Design and Material Selection – Understanding the product application, intended market and performance, end use objectives, and use environment

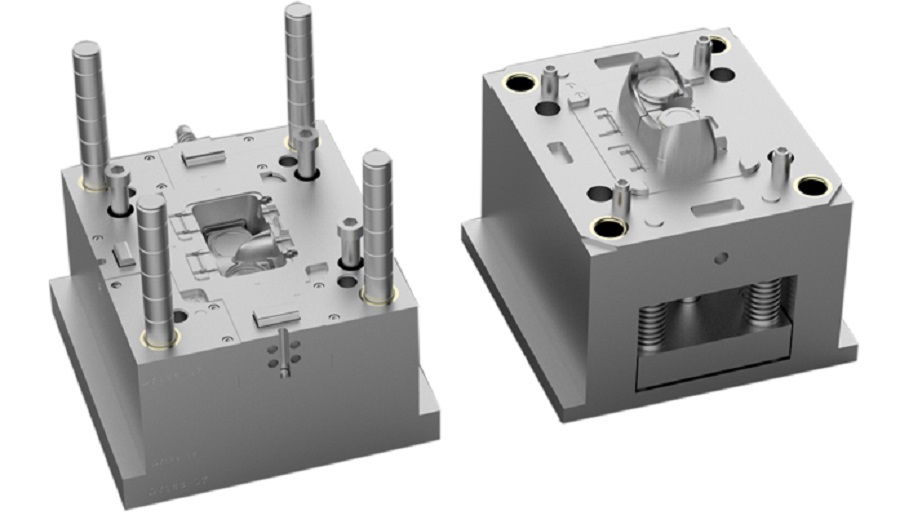

- Tool Design and Mold Building – Design for mold efficiency, longevity and performance

- Molding Process – Injection molding technologies, cycle times, material flow and employing scientific injection molding

- Quality Systems and Metrology – Focusing on tolerances, part inspection, steel safe mold and more

- Automation Systems – In the injection molding process and downstream – making it simple and lean

Advantages

Our experience, along with the latest innovations in custom plastic injection molding technologies, has provided us with a competitive advantage on each and every project.

a. Multi-shot molding

b. Molded-in color

c. In-mold decorating (IMD)/In-mold labeling (IML)

d. Overmolding

e. Insert molding

f. Gas assist molding

g. Stack molds

h. Robotics and Automation

i. Horizontal plastic injection molding

j. Vertical plastic injection molding

k. Full secondary and integrated operations

Expertise

FacFox Plastics expertise in custom injection molded plastics includes:

a. ISO Class 8 clean room molding

b. Large part molding

c. Thin wall plastic packaging

d. Complex plastic parts and assemblies

e. Metal to plastic conversions

FacFox custom injection molded plastics are providing competitive advantage for OEMs in many applications and markets, including medical/health care (medical disposables, medical devices, medical housings and components, medical packaging), utility vehicles, packaging, agriculture, construction, lawn and garden, recreational vehicles, trucking, marine, consumer products, plumbing and water, and appliances.

The FacFox Team operates over 60 horizontal and vertical plastic injection molding machines ranging from 50 to 3000 tons. All of our plastic injection molding facilities follow the same systems and procedures, provide the same high level of quality and service.

Add a Comment

You must be logged in to post a comment