3D printing is a technology that allows you to create physical objects from digital models. You can print anything from toys and jewelry to tools and prosthetics. But did you know that you can also print chain mail?

Chain mail is a type of armor made of interlocking metal rings. It was used by warriors and knights in medieval times to protect themselves from swords and arrows. Chain mail is flexible, durable, and resistant to piercing and slashing.

But metal chain mail is also heavy, expensive, and hard to make. You need to cut and bend thousands of metal rings, and then weave them together by hand. That’s why most people today only use chain mail for cosplay, reenactment, or decoration.

However, with 3D printing, you can make your own chain mail easily and cheaply. You don’t need any metal or tools, just a spool of plastic filament and a 3D printer. And you can customize the size, shape, and color of your chain mail to suit your needs and preferences.

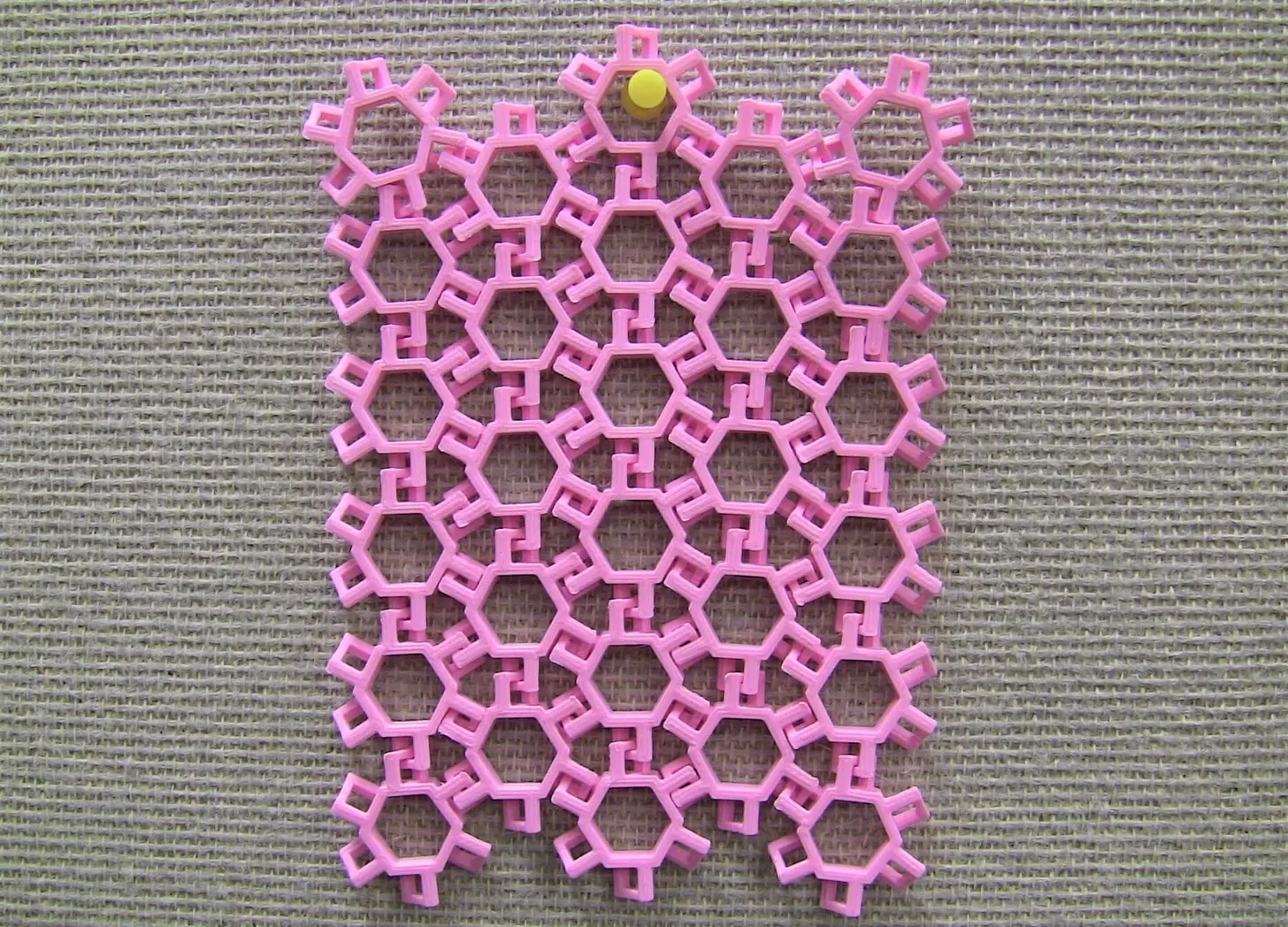

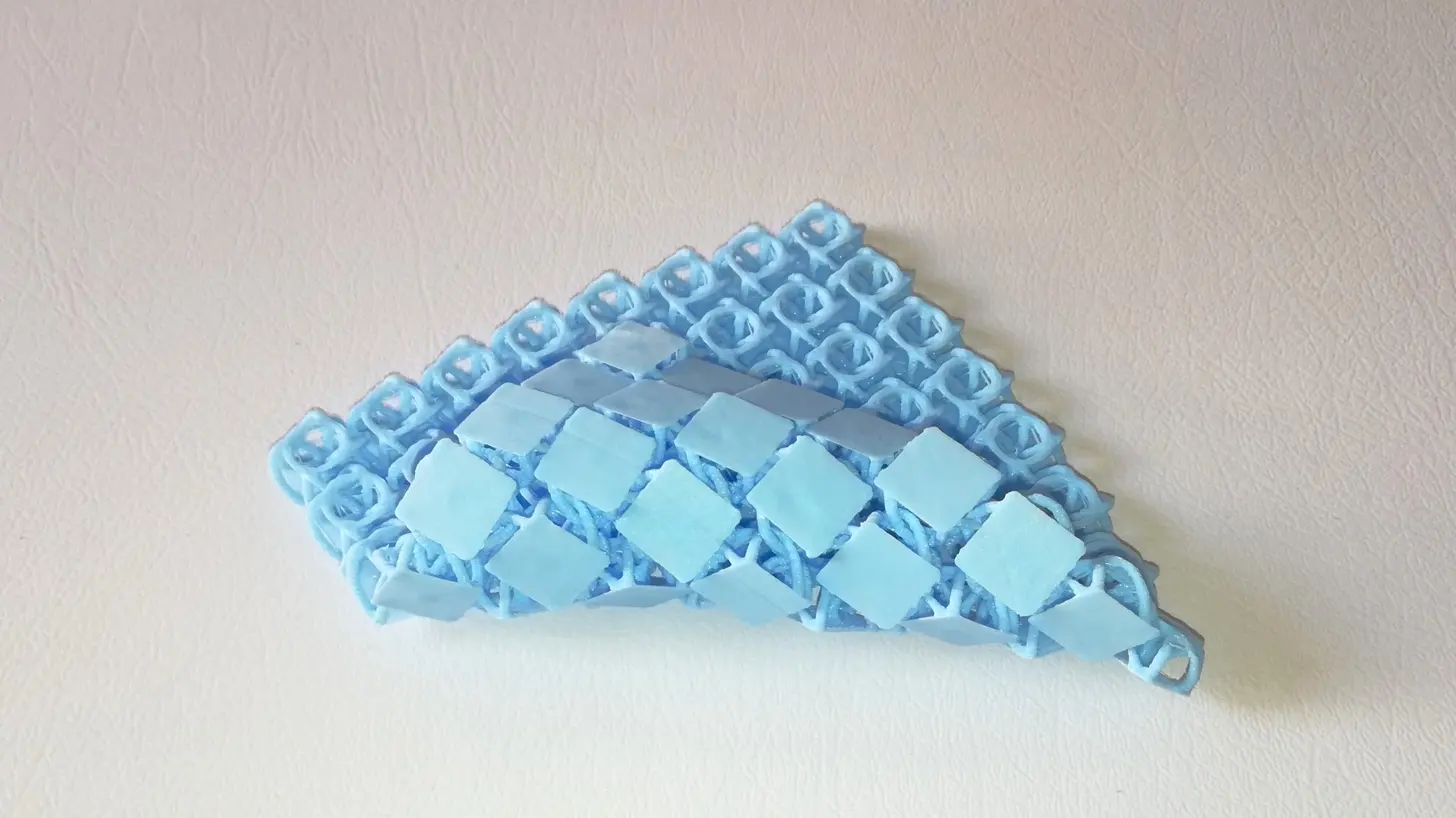

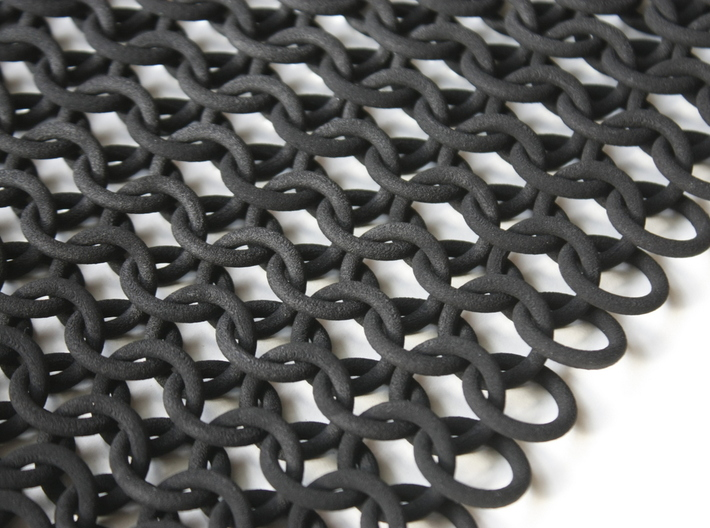

Here are some 3D models of Chain Mail

There are chain mails in the shape of squares, rectangles, hexagons, scales, letter “H”, spikes, prisma, etc. You can get a lot of inspirations from these designs and turn them into plastic cloth, necklaces, cat proofs, cosplay armors, etc. To find more, you can check here.

And if you are looking for a reliable and affordable service to 3D print your chain mail with TPU plastic, you might want to check out FacFox’s TPU printing services. FacFox is a professional 3D printing company that offers high-quality TPU printing with various technologies, such as FDM, MJF, or SLS. They also have a fast turnaround time and a friendly customer support team. You can send your 3D model to info@facfox.com and get an instant quote for your order.

FDM 3D Print Chain Mail with TPU Filament

One of the best FDM materials for 3D printing chain mail is TPU, or thermoplastic polyurethane. TPU is a flexible and durable plastic that can bend and stretch without breaking. It has a higher glass transition temperature than PLA (60-65°C), at around 80°C, and can handle low temperatures well without becoming brittle. TPU also has qualities that other materials don’t have, such as vibration dampening, shock absorption, and incredible elongation.

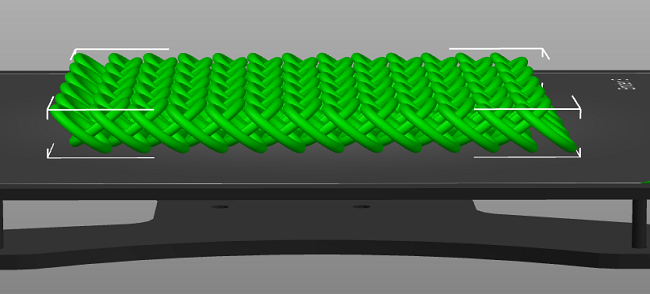

To 3D print chain mail with TPU, you need to choose a suitable design. There are many different designs available online for free or for a small fee. Some of them look futuristic and angular, while others look more like traditional chain mail. If you want to make a medieval fantasy themed costume, you probably want to use a design that uses round rings.

There are different ways to print round rings with TPU. The simplest way is to print them flat on the bed, but this requires the rings to be printed at an angle instead of flat on the bed. This causes issues with the rings becoming dislodged from the print bed, because they only have a little bit of surface area touching the bed. To avoid this problem, you can use some adhesive spray or tape to secure the rings to the bed.

Another way to print round rings with TPU is to print them in a curved shape. This allows the rings to be printed in more of a flat configuration, and still be interwoven together. The downside of this method is that it changes the shape of the rings slightly, making them less authentic.

A third way to print round rings with TPU is to print them with built-in grooves. These grooves allow for the space of the other rings, so that they can fit together snugly. This method preserves the shape of the rings better than the curved method, but it also adds some extra material to the rings.

Once you have chosen your design and printed your chain mail sections, you need to assemble them together. You can do this by using some pliers or tweezers to open and close the rings, or by using some glue or heat to fuse them together. You can also add some clasps or buckles to make your chain mail easier to wear.

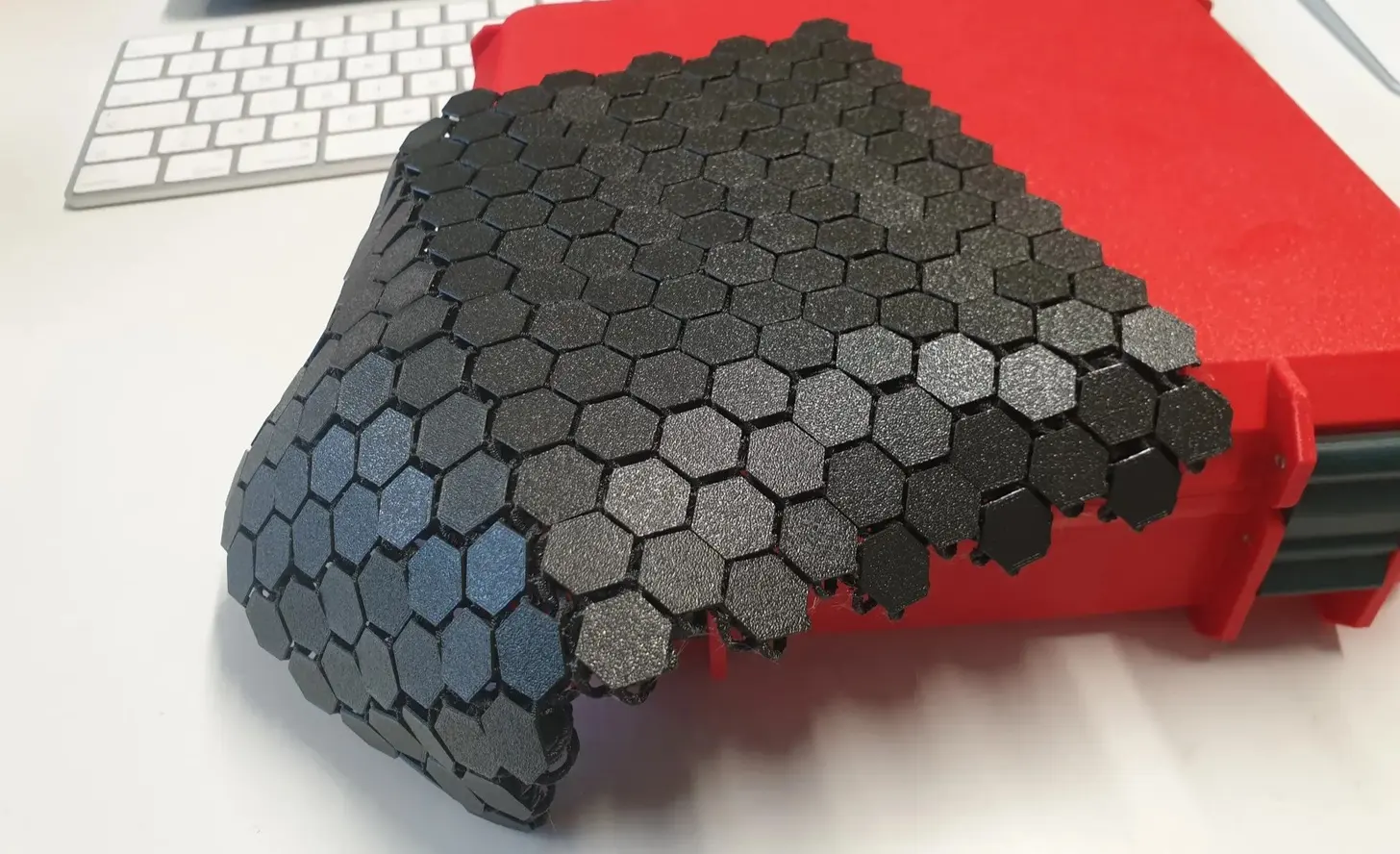

SLS/MJF 3D Print Chain Mail with TPU Powder

Another option for 3D printing chain mail with TPU is to use powder-based technologies such as Multi Jet Fusion (MJF) or Selective Laser Sintering (SLS). These methods use a heat source to fuse particles of thermoplastic powder together within a build chamber filled with powder– often nylon or TPU.

The difference between MJF and SLS is that MJF uses a fusing agent and an infrared lamp to selectively fuse the powder, while SLS uses a laser beam to selectively sinter the powder. The fusing agent also acts as a color agent in MJF, allowing you to print in different colors. However, both methods produce parts that are high in resolution and have consistent isotropic mechanical properties.

To 3D print chain mail with TPU powder, you need to choose a suitable design as well. There are also many designs available online for MJF or SLS printing. Some of them are similar to the ones for FDM printing, while others are more optimized for powder-based technologies.

The advantages of using MJF or SLS over FDM are that: you can print multiple parts at once in the same build chamber, and you don’t need any support structures for your parts. This means that you can print more complex and intricate designs without worrying about overhangs or bridges. Also, the connected rings can all be closed, so they won’t fall apart. But you can make the rings on the edges open, so the pieces of chain mail can be assembled into a larger one.

The disadvantage is that the parts require more post-processing steps. After printing, the parts need to be depowdered, bead blasted, and dyed (if desired). These steps can add to the cost and turnaround time of your parts.

Enjoy your new cosplay props!

Now you have it: your own 3D-printed chain mail made with TPU! You can use it for cosplay, reenactment, decoration, or even as a smart fabric. Some researchers have developed a 3D-printed chain mail fabric that can stiffen on demand by applying an electric current. This could have applications in wearable technology, robotics, and medicine.

3D printing chain mail with TPU is a fun and creative way to explore the possibilities of 3D printing. You can make your own armor that is flexible, durable, and customizable. And who knows? Maybe one day you’ll be able to print your own mini sun.