How much do you know about 3D printing’s subtractive rival, CNC milling? We take a deeper look into the technology, including what it is and what types of machines and tools exist.

What Is a CNC Machine?

Computer numerical control (CNC) is programmed code that represents instructions for precise movements to be carried out by machines. Indirectly, this code defines how to automatically create, produce, or transform a virtual object into a real one.

Based on this definition, a CNC machine must interact with a computer equipped with software that transforms numerical code into Cartesian coordinates. This allows the machine to work with a high degree of precision, just like a robot.

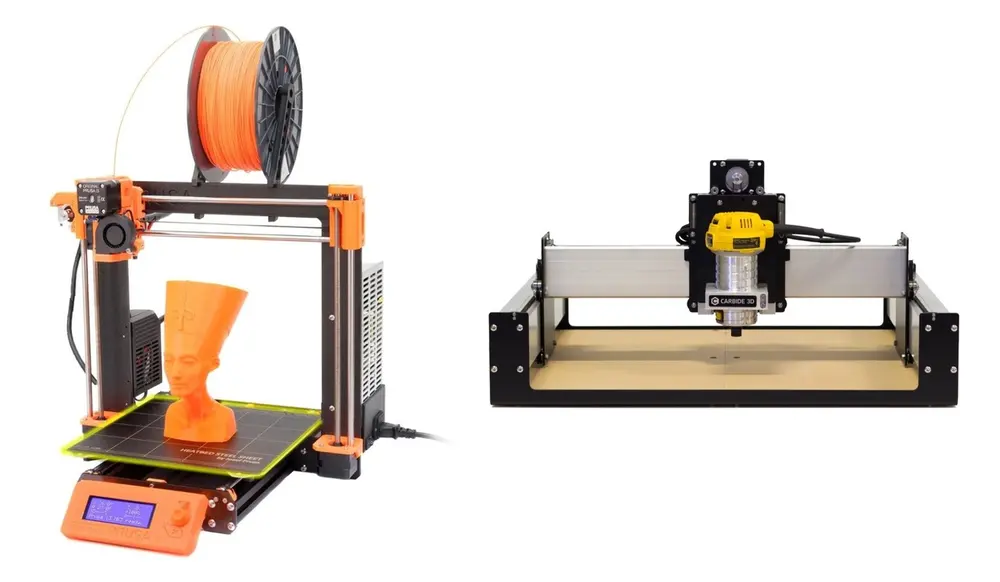

A CNC machine transforms raw material into a finished model through different methods, either by adding (additive) or removing (subtractive) material. The available techniques depend on the type of machine. A 3D printer or CNC milling machine are fine examples of additive and subtractive CNC machines, respectively.

What Is a Milling Machine?

Milling is the process of cutting and drilling material (like wood or metal). A milling machine, regardless of whether it’s operated manually or through CNC, uses a rotating cylindrical tool called a milling cutter. It is held in a spindle and can vary in form and size.

The main difference between a milling machine and any other drilling machine is the ability to cut in different angles and move along different axes. For this reason, there are several kinds of milling machines, which are designated by number of movement axes:

- 2-axis milling machines can cut holes and slots in the x- and z-axes. In other words, this machine will only cut vertically and horizontally (but only in one direction).

- 3-axis milling machines add the y-axis. This is the most common variety of milling machine. You can cut vertically and in any direction, but an object like a sphere will need to be done one half at a time. This is because, even with three axes, it’s not possible to cut from below.

- 4-axis milling machines are more complex because they add the ability to rotate the x-axis, similar to a lathe.

- 5-axis milling machines incorporate rotation in both the x- and y-axes. This is the most complete milling machine you can have. It allows you to shape bones, aerospace structures, car models, medical products, and pretty much anything else you can imagine.

- CNC milling machines can have any number of axes (2 to 5) but are operated through a computer. No manual operation required.

Types of Milling Machines

Now we know that a CNC milling machine is any milling machine controlled through a computer. Yet, apart from axis classifications, there are still several types of milling machines, whether manual or CNC:

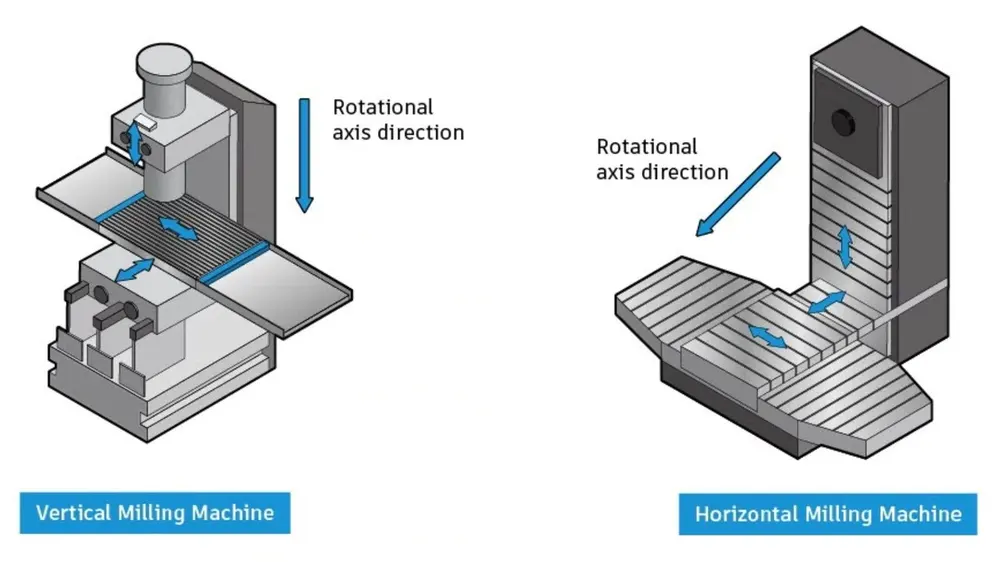

- Vertical mill: This 3-axis milling machine consists of a table, which acts as a work surface, below an arm, to which the spindle is attached. Both the table and the arm are connected to a vertical column, and the spindle is vertically oriented. Generally speaking, the table moves up and down along the z-axis in order to meet the arm, which is fixed. However, how the table and the spindle move in relation to each other depends on the type of vertical mill. In a turret vertical mill, the spindle is stationary and the table moves along both the x- and y-axes. In a bed vertical mill, the table can only be moved along the x-axis, while the spindle can travel along the length of the arm in the y-axis direction.

- Horizontal mill: This milling machine is similar to a vertical mill, except that the spindle is oriented horizontally instead of vertically. While generally considered less versatile than vertical mills, horizontal mills are better-suited to longer or heavy pieces of work. A universal horizontal mill has the additional capacity to rotate the table around the z-axis (making it a 4-axis milling machine).

- Knee mill: Any kind of mill where the table moves up and down the column according to an adjustable knee.

Types of Milling Tools

For each machine, you can find different sets of tools that perform different cuts. Some bigger, more industrial machines can even change the tool mid-job.

Different tools are designed for different materials, and it’s important to choose the perfect tool for the job. Failure to do so could result in unwanted damage to the material, the tool, or both.

Let’s compare wood and steel: If you choose an overly strong steel tool to cut wood, you could end up losing the workpiece. Meanwhile, if you use wood tools for steel, you will certainly end up breaking the tool and the machine.

As stated earlier, the most basic tool is a milling cutter, which kind of resembles a drill bit, but with teeth designed to remove material in ways other than just drilling. Cutters can vary in shape and size as well as in teeth orientation and spacing.

Why Is CNC Milling Important?

Digital technologies and CNC milling machines allow for the resolution of many problems which cannot be easily solved using prior methods. The technology approaches the working process in a way that’s both more effective and more efficient.

For example, without a CNC milling machine machine, the process of cutting metal for car parts or even aerospace components would be much riskier. With the support of computer programs, one can access and create high definition designs that are easily converted into Cartesian coordinates. This process even helps lower the costs of prototyping!

But these technological machines aren’t only for industrial use. Here are a few other areas to which CNC milling can be applied:

- cabinets

- furniture

- woodworking

- instruments

- aluminum machining

- prototyping and modeling

- sculpture

- signs

There are also a wide range of (hard and soft) solid materials that a CNC milling machine can cut:

- aluminium

- steel

- titanium

- copper

- bronze

- zinc

- PVC

- nylon

- wood

- plywood

- extruded polyurethane

- stone

If you’re a hobbyist looking for further guidance, take a look at our article on how to choose the right material for CNC milling.