In addition to printers, Ultimaker manufactures filaments in a variety of materials. Read on to learn more about Ultimaker filament options!

From the Makers of Cura

Ultimaker is a manufacturer of professional 3D printers such as the Ultimaker 2+ Connect and Ultimaker S5. While their printers certainly are popular, they’re perhaps even more well-known for Ultimaker Cura, the open-source 3D slicer for FDM printers. Cura lets users build custom slicing profiles based on specific printers as well as specific materials – a feature that integrates nicely with Ultimaker’s line of filaments.

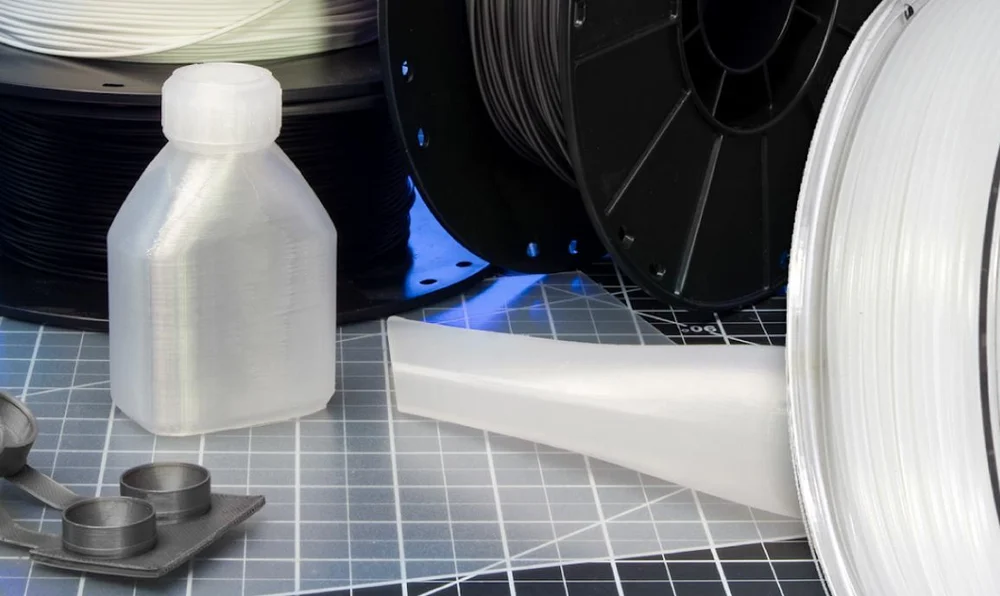

The company manufactures filaments in a wide range of materials from PLA to CPE. These filaments are usually compatible with Ultimaker 3D printers and are made with a high level of quality control to maintain Ultimaker’s great reputation in the 3D printing community.

In this article, we’ll discuss some of Ultimaker’s most noteworthy filaments, everything from their basics to some of their more advanced filaments. Before we get into all of that, though, we’ll first go over some details common to all Ultimaker filaments.

The Ultimate Filament

Ultimaker’s filament is a little more expensive than other brands out there, but as a well-known and reputable manufacturer of 3D printing products, their aim to deliver high-quality filaments. To fulfill this aim, they test their filaments for quality and ease of printing.

Despite the range of materials on offer, you’ll find some commonalities across all of Ultimaker’s filaments, namely their diameter, NFC tagging, and pre-built Cura profiles.

Diameter

All Ultimaker filaments have a diameter of 2.85 mm, as the filament is tailored to Ultimaker printers, which require this diameter. As such, one could say that Ultimaker filament is technically made for Ultimaker printers. This diameter is a lot rarer than the common 1.75-mm diameter filament and is typically used on higher-end machines (e.g. LulzBot).

According to some users, the larger diameter of Ultimaker filaments makes the filament more rigid, and it’s easier to print flexible materials. A larger diameter also means that more material comes out of the nozzle, and for this reason, it has to be printed at slower speeds.

NFC

All Ultimaker spools of filaments have a built-in NFC filament information chip. Certain Ultimaker printers (the Ultimaker 3 and S5, for example) read and scan this chip to detect the material, which enables them to keep track of filament usage.

Cura Profiles

Each type of Ultimaker filament has its own pre-built Cura slicer profile, which eliminates the need for a long tuning process that you would have to go through with third-party filament brands. This makes it easy to load another spool onto your Ultimaker printer and continue printing without having to print a bunch of calibration models.

BASICS

In this category, we’ll go over the standard 3D printing filaments from Ultimaker, including their PLA, Tough PLA, ABS, nylon, TPU, PC, and PETG filaments.

PLA

First up is Ultimaker’s PLA filament, and if you’ve never heard of it, PLA is the most widely-used 3D printing material out there due to how easy it is to use. Even though this filament is Ultimaker’s “normal” PLA option, it still produces stiff and strong parts given its great physical properties.

According to Ultimaker, their PLA has a high hardness value, good impact resistance, and excellent flexural strength (which refers to the amount of bending stress a material can take just before it breaks). This filament’s higher flexural strength is a big advantage because most PLA materials are super brittle. Additionally, MatterHackers, an online seller of Ultimaker PLA, praises the filament for yielding dimensionally accurate parts.

PLA is a pretty easy-to-print material, however, this doesn’t mean Ultimaker PLA doesn’t have some issues. Some users have noticed that the filament tends to cause extrusion issues and is prone to stringing when used with another material (via dual extrusion).

- Available colors: 11 colors including primary and some secondary colors, transparent, and of course, black and white

- Temperatures: Hot end 200-210 °C; heated bed 60 °C

- Size: 0.75 kg

- Price: ~$50

Tough PLA

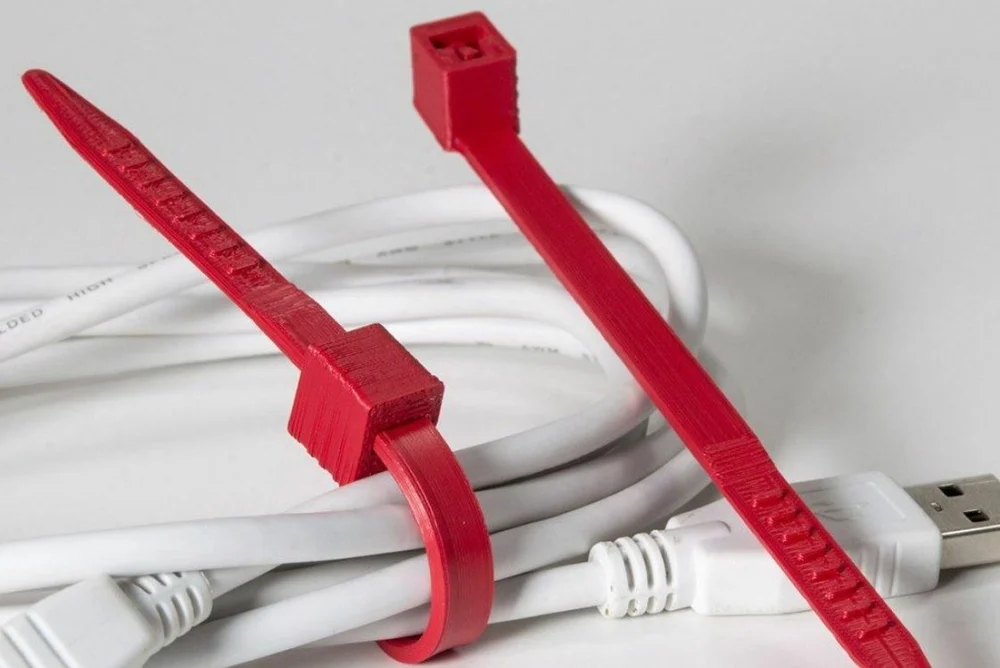

Ultimaker also offers Tough PLA, and when they say “tough”, they mean it. This filament has an impact strength close to double that of their standard PLA filament, which was already tough to begin with. Ultimaker’s Tough PLA has strength properties similar to ABS, but they claim to have maintained the easy printability of regular PLA.

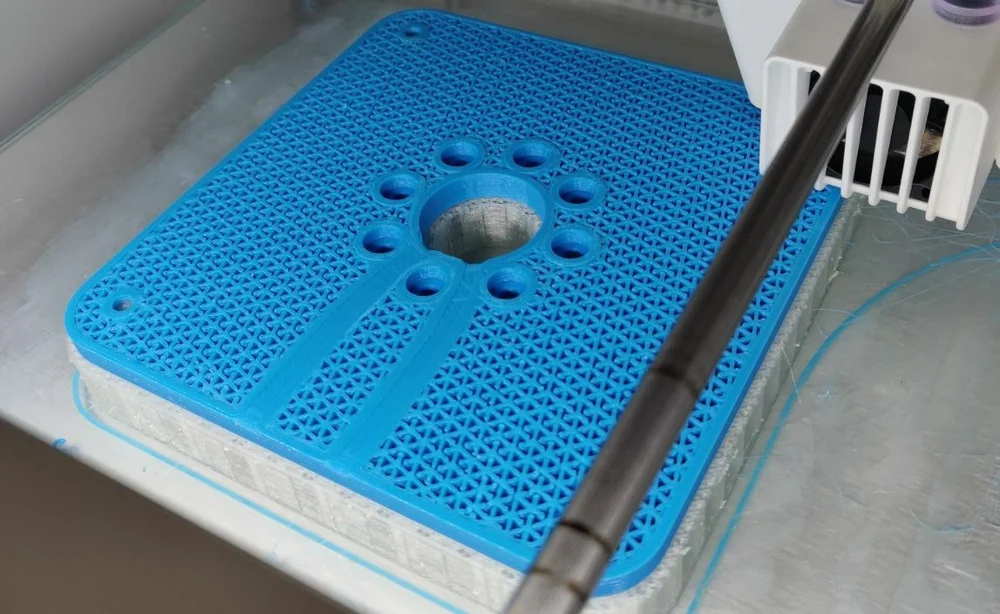

Ultimaker highlights how this filament has greater machinability than other filaments and suggests using this filament to print machinable parts and functional prototypes. For more ideas, one maker used Ultimaker Tough PLA to make steel forms. Other users have also commented on how easy it was to set up this material on their Ultimaker printer.

- Available colors: Red, green, black, white

- Temperatures: Hot end 210-220 °C; heated bed 60 °C

- Size: 0.75 kg

- Price: ~$50

ABS

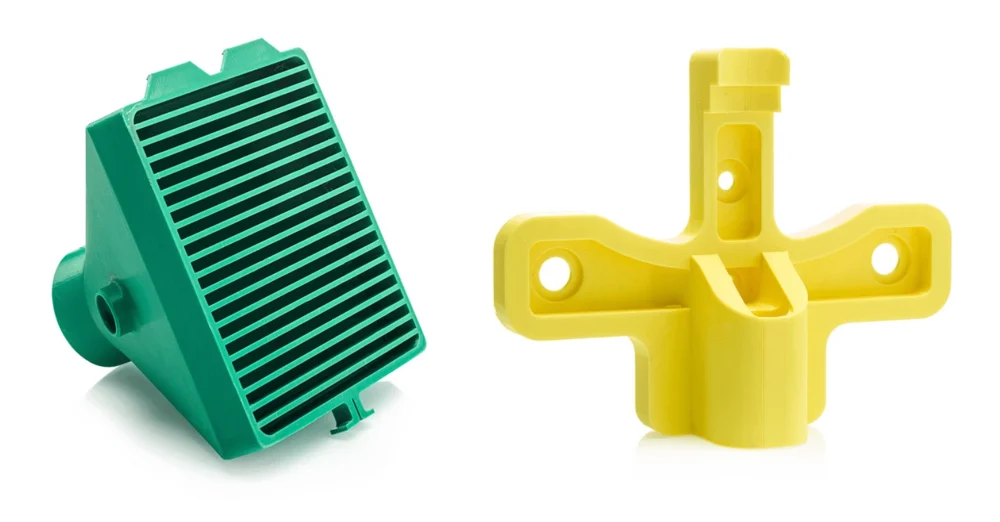

ABS is usually considered a difficult material to print due to its sensitivity to temperature changes. In comparison to their PLA options, Ultimaker ABS will definitely be more difficult to print. But, in exchange, parts will be much stronger and soluble in acetone, which you can use to layer smooth prints.

According to Ultimaker, their ABS filament has high hardness and impact strength as well as good flexural strength. They also focus on the layer adhesion aspect of their ABS filament, stating that layers bond well when printed in an enclosure (like on the Ultimaker S5).

Due to the material’s strength, Ultimaker recommends using their ABS filament to print end-use components, concept models, functional prototypes, and more. Examples might include door hinges, model mechanical engines, and interior car parts. Another example is a handguard, which one maker printed successfully using this material.

In terms of post-processing, some makers have mentioned that parts printed in Ultimaker ABS take a little longer than usual to smooth when you use acetone vapor smoothing techniques. So, keep that in mind if you’re thinking of smoothing your prints.

- Available colors: 10 colors including the primaries, black, white, and two shades of gray

- Temperatures: Hot end 225-260 °C; heated bed 80-90 °C

- Size: 0.75 kg

- Price: ~$50

Nylon

Nylon is a strong, impact-resistant 3D printing material, and Ultimaker Nylon is one to reckon with. According to the company, the filament is resistant to high temperatures and different chemicals, including alkalis. It also has an extremely high elongation before breaking (210% according to Ultimaker), meaning this filament is not brittle at all.

Sadly, Ultimaker’s Nylon filament is more expensive than the previous filaments, but if you need high-strength parts that aren’t brittle, this filament might be your match. They say applications include end-use parts, functional prototypes, and industrial modeling.

- Available colors: Black, transparent

- Temperatures: Hot end 230-260 °C; heated bed 60-70 °C

- Size: 0.75 kg

- Price: ~$70

TPU 95A

TPU is the king of 3D printable flexible materials, and while it can be difficult to print, its flexibility makes it a great material option. Ultimaker’s TPU filament has a value of 95A on the Shore Hardness scale, with the ‘A’ representing softer and more flexible materials. The company points out how this filament is very much like rubber when it comes to flexibility, with a tested 580% elongation at break.

According to some users, Ultimaker’s TPU filament tends to string a lot when printed, but this isn’t specific to Ultimaker’s TPU. In fact, stringing is a common occurrence when printing flexible materials, especially when using a Bowden extrusion setup like the Ultimaker S5. Despite the stringing, though, other users have found success with Ultimaker TPU, stating that it yields excellent prints.

Ultimaker lists that their TPU filament can be used for concept models, fit testing prints, and more. For more 3D printable TPU ideas, you can check out our article on the best flexible 3D prints.

- Available colors: Blue, red, black, white

- Temperatures: Hot end 220-235 °C; heated bed 70 °C

- Size: 0.75 kg

- Price: ~$70

PC

Polycarbonate, known as PC, is one of the strongest 3D printing materials. In addition to its strength, Ultimaker PC is great for parts that must withstand high temperatures. According to the company, this filament will retain its form up to 110 °C. Additionally, they say it has high toughness and impact strength as well as good tensile strength (which is a measure of how much of a load or stress a material can take before it stretches and breaks).

Of the three color options offered by Ultimaker, transparent is quite useful, as it would be great for lighting; fixtures made of PC could get hot and wouldn’t deform. Ultimaker suggests using this filament to print molds, end-use parts, short-run manufacturing components, and more.

- Available colors: Black, white, transparent

- Temperatures: Hot end 260-280 °C; heated bed 110 °C

- Size: 0.5 kg

- Price: ~$70

PETG

After marketing research indicated increased use of PETG among makers, Ultimaker developed and released their own PETG filament, which hit the market in May 2021. PETG is notoriously tricky to print, and noting the results of their tests of competitors’ offerings, the company says their PETG has been optimized for Ultimaker users, increasing the likelihood of print success on the first go.

Given the material’s chemical and temperature resistance, ideal use cases include functional prototypes, industrial parts, and manufacturing aids. As the filament released recently, we haven’t found much buzz about it on community forums or YouTube. So, we’re eager to see how makers respond to Ultimaker’s newest filament in the coming months.

- Available colors: 14 colors including all the usual suspects as well as fluorescent yellow and translucent red, blue, and green

- Temperatures: Hot end 225-245 °C; heated bed 85 °C

- Size: 0.75 kg

- Price: ~$50

UNIQUE & ADVANCED

In this category, we’ll go over the more advanced types of Ultimaker filaments including PVA, Breakaway, CPE, CPE+, and PP.

PVA

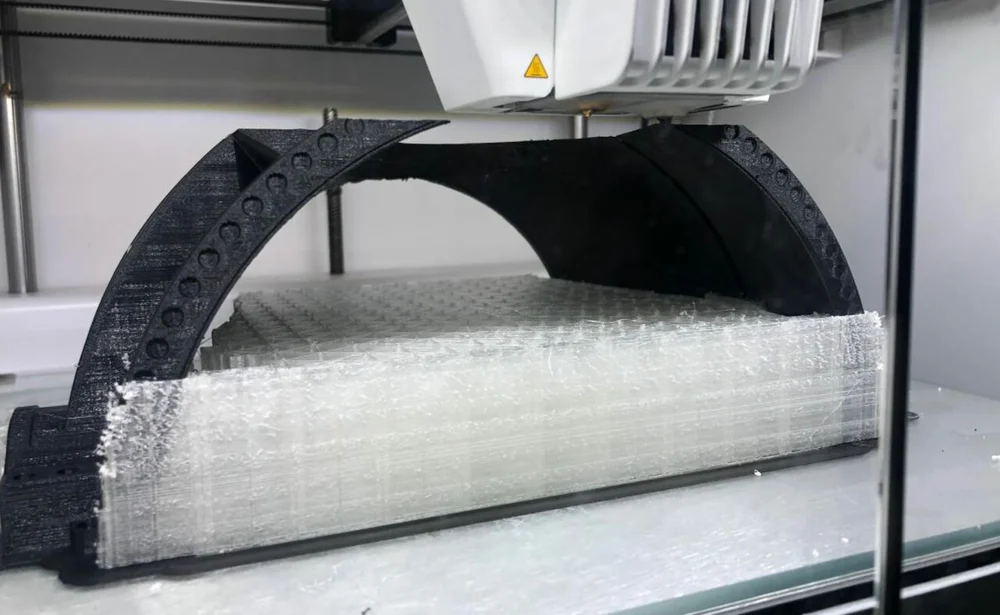

PVA is a water-soluble material that’s most commonly used for 3D printing support material. You can leave a part in water, and the supports printed will dissolve. Ultimaker PVA is meant for dual extrusion 3D printers, like the Ultimaker S5. That’s because you can’t reap the benefits of a dedicated support material without being able to print two filaments at once.

Their filament is non-toxic and 100% biodegradable, releasing no dangerous by-products when mixed with water. According to Ultimaker, you can use plain tap water to dissolve PVA structures on a part, so don’t worry about using filtered water.

Ultimaker highlights how well PVA filament adheres to parts printed in PLA, CPE, and nylon materials. However, these claims are countered by some user’s negative experiences using PVA with other materials. The filament is known to be pretty hygroscopic, and some makers have faced extrusion issues due to wet PVA filament. To avoid some of these issues, make sure to properly store this filament to prevent its absorption of humidity from the air.

- Available color: Transparent

- Temperatures: Hot end 215-225 °C; heated bed 60 °C

- Sizes: 0.35 kg, 0.75 kg

- Price: ~$100 (0.75 kg)

Breakaway

Ultimaker Breakaway is also a filament meant for printing supports. Like PVA, you’ll need a dual extrusion machine to get the most out of the material. It’s different from PVA, though, because Ultimaker’s Breakaway filament snaps right off your prints, leaving a smooth surface without any post-processing. If you’re eco-minded and want to save water or you simply don’t want to soak your parts (which can take hours), Breakaway is the better option.

Ultimaker highlights how this filament leaves a much cleaner surface on the overhang’s underside than if you were to use another material for supports. The filament works well with basically all of Ultimaker’s filament offerings.

- Available color: Transparent

- Temperatures: Hot end 215-230 °C; heated bed 60 °C

- Size: 0.75 kg

- Price: ~$70

CPE and CPE+

Ultimaker’s CPE and CPE+ filaments are both all-around amazing. Their CPE filament is reliably dimensionally accurate, chemically resistant, super tough, impact-resistant, non-brittle, and hard. The only significant difference between it and CPE+ filament is the latter is more resistant to wear and heat.

These materials are known to be similar to PETG due to their enhanced strength properties but are more like ABS due to the difficulty of printing with them. Many users experience a lot of stringing when printing CPE, and this filament can over-adhere to the bed, just like PETG is known to do.

In terms of possible applications, Ultimaker recommends using their CPE and CPE+ filaments to 3D print parts like mechanical components that need to be chemically resistant and assemblies that need to be dimensionally accurate.

- Available colors: 9 colors including the primaries, black, white, a couple of gray shades, and transparent

- Temperatures: Hot end 250-275 °C; heated bed 110 °C

- Size: 0.75 kg

- Price: ~$60-$70

PP

Lastly, polypropylene, or PP, is a material known for yielding chemically resistant and lightweight yet durable parts. Ultimaker PP boasts these properties, and the company advertises its chemical resistance and low density.

They say the material has a high electrical resistance, so it can be used for insulative plastic parts. It also returns to its original shape after being physically deformed, bent, or flexed. Similar to the other filaments, Ultimaker suggests prototypes as well as end-use and machined parts as possible applications for the filament.

- Available color: Transparent

- Temperatures: Hot end 205-220 °C; heated bed 85-100 °C

- Size: 0.5 kg

- Price: ~$50