Although soft PLA and TPU have a lot in common, minor differences affect their applications. Explore the differences between soft PLA and TPU in this handy guide.

Flexible Filament 101

One major perk of 3D printing is its flexibility – both literally and figuratively. If you have a niche material requirement, chances are there’s a filament for it. For instance, flexibility can be desirable in models to increase durability or ease of use, among other things.

Most flexible filaments are made from a polymer of hard plastic and rubber, called thermoplastic elastomers. The flexibility of the material depends on the ratio of these two compounds. So it’s possible to print objects that are completely malleable but snap back like a rubber band, all the way up to objects like car tires that flex when pressured but otherwise maintain a firm shape.

There are a few types of flexible filament out there, all with their own characteristics and strengths:

- TPE: Short for thermoplastic elastomer, TPE is often used as a generic term for flexible filament, as it covers a broad range of flexible materials.

- TPU: Short for thermoplastic polyutherane, TPU is slightly more rigid than TPE, which makes it easier to print with typical extruders.

- TPC: A co-polyester filament partially made from bio-oils. This filament can buckle very easily in your extruder, so you have to print it very slowly to prevent any warping.

- PCTPE: Short for plasticized copolyamide TPE. That means this flexible filament has nylon in its mix, which adds nylon’s durability to TPE’s flexibility. However, this also sacrifices some of TPE’s natural flexibility.

- Soft PLA: This is a flexible variant of biopolymer polylactic acid (commonly known as PLA), one of the most common 3D printing filaments. Read on to discover its awesome properties!

Printing Tips

Flexible filaments are great at dampening impacts and vibrations, have a long shelf life, and are extremely durable, but they are more difficult to print than filaments with stiffer base materials.

You can improve your chances of a good flexible print by using a direct drive extruder, which makes the distance between the drive gear and the melt zone as short as possible within the printer. This makes it easier for the flexible filament to travel through the printer without getting bunched up.

Alternatively, if you really don’t trust your setup (or don’t have one), you can also turn to a 3D printing service and reap the benefits of professionalism. Find the right provider (and price) at FacFox, 3D printing and price comparison service.

What Is it?

As we mentioned above, soft PLA is a special type of PLA 3D printing filament. It’s made with natural materials, such as cornstarch, tapioca roots, or sugarcane. Pellets of those materials are melted down into a liquid that is shaped, dried, and hardened into a long, thin filament and wound onto a spool for 3D printing.

Soft PLA is treated with additional chemicals to take away much of the natural brittleness of regular PLA. When those chemicals are added, the PLA gains characteristics of rubber. It’s able to withstand manipulations to its shape when pressure is applied, springing back to its original shape once the pressure is taken off.

Soft PLA also retains the ability of rubber to absorb vibrations and impacts. It’s useful for objects like tires that need to keep their shape to work but are constantly exposed to pressures that would break or crack a material without any give.

In the following, we’ll break down soft PLA’s characteristics into pros and cons and then see how it compares to TPU filament.

The Pros

Soft PLA’s advantages over regular PLA include:

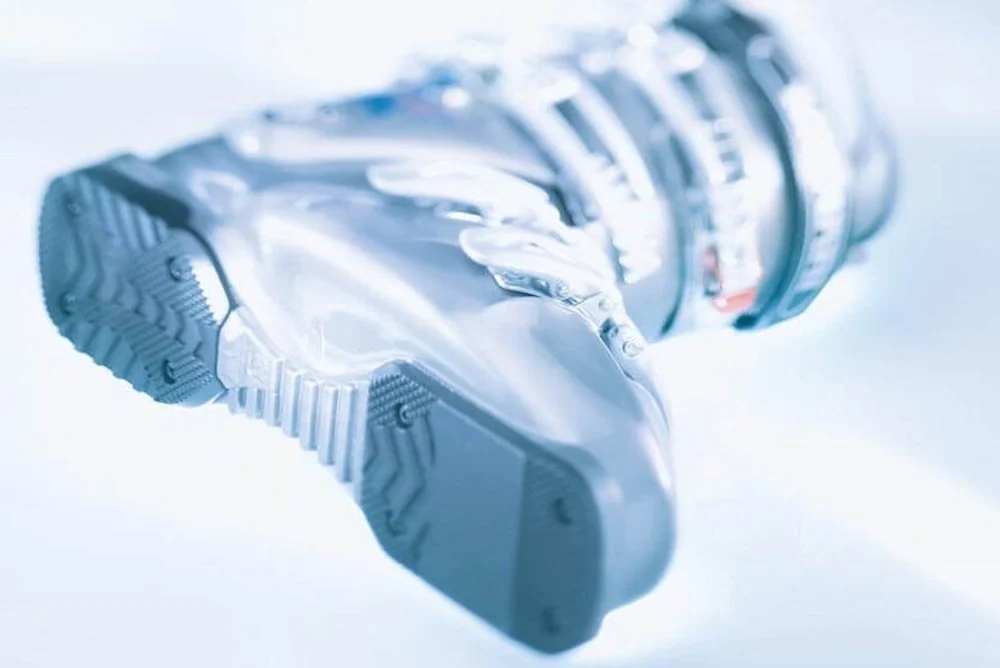

- Ergonomics: Because of its unique blend of firmness and give, soft PLA makes an excellent ergonomic material. Objects like pen grips, shoe sole inserts, and more are prime candidates for soft PLA.

- Low carbon footprint: Soft PLA does use more chemicals than regular PLA filaments, and that’s what makes soft PLA flexible. But its carbon footprint remains lower than any other flexible filament you can find. Plus, in many instances, soft PLA will remain biodegradable like PLA.

- Durability and flexibility: The main attraction for soft PLA is, of course, its flexibility. This is especially significant as an added characteristic to PLA filament since PLA creates a very brittle final product. Those who want to harness PLA’s strengths can now take advantage of soft PLA for objects that were previously impractical to print with PLA, such as tires, cell phone covers, and other things that need to be strong but flexible.

- Vibration dampening: Because of its combination of flexibility, strength, and durability, soft PLA makes good dampening components. That makes it a great cover for machine parts that absorb a lot of movement from those around them.

The Cons

The biggest challenge when using soft PLA filament is learning what does and doesn’t work to make it do what you want. It’s got a few downsides that also stem directly from its added flexibility properties:

- Printing difficulty: The major disadvantage of using soft PLA is that it’s prone to acting out during the actual 3D printing process. The same qualities that make it flexible take away much of the tension that filaments require to go through the extruder while retaining their string-like shape. Thus, soft PLA is prone to clogging, bubbling, and bunching together in the nozzle, while also being extremely adhesive yet formless when directed onto the printing bed. This makes it difficult to “steer” soft PLA filament into your desired shape. However, there are plenty of tips and tutorials online that help combat these tendencies. The most helpful of these is to slow down your printing speed, which gives the soft PLA the heavier guidance it needs when shaping layers of an object.

- Special hardware: There are also plenty of add-on tools that help with soft PLA and other flexible filaments, such as a direct drive extruder. A direct drive extruder makes the filament’s journey from its feeding entrance to the print bed as short as possible, which helps keep soft PLA from catching on bends on its way out. You can also buy specific types of printer bed adhesion liquids that make your printing area hold onto the soft PLA while printing.

- Poor support material: Because of its flexibility, soft PLA is not a good support filament. If you’ve got an object design that has a lot of gaps or overhangs, you’re going to need a stiffer material. Objects with unbroken planes work best when printing with soft PLA.

Compared to TPU

Soft PLA and TPU have a lot in common, but there are a few notable differences:

- Stiffness: TPU is slightly stiffer than soft PLA. Based on the standardized Shore scale of rigidity, TPU measures 94A – 95A, which is a few notches above soft PLA fialment’s average measurement of 92A. This may not be a big difference on paper, but TPU is easier to work with.

- Food safety: Soft PLA is food-safe. Its biological components make it safe to use for food containers and utensils. That also makes it a good choice for 3D printed objects that will inevitably touch or go into someone’s mouth, like toys for young children. That doesn’t mean eating the soft PLA itself is safe, of course, but it’s perfectly fine for coming in contact with edible objects (as long as you take the necessary post-processing precautions). TPU, on the other hand, is a chemical sandwich you should avoid.

- Abrasion reisistance: TPU has higher abrasion resistance. Because it’s a little more rigid, TPU objects can stand up to more repetitive contact than those made out of soft PLA. That makes TPU better for things like machine parts.

- Flexibility: Soft PLA is more flexible. If you need a flexible filament to print anything to wear, soft PLA is the way to go. Its softer properties make it easy to deform with the natural movements of, for example, your waist within a belt, so that it doesn’t break as soon as you bend over.

Source: https://all3dp.com/2/what-s-soft-pla-filament-how-does-it-compare-to-tpu/