What Does It Mean and Where Does It Come From?

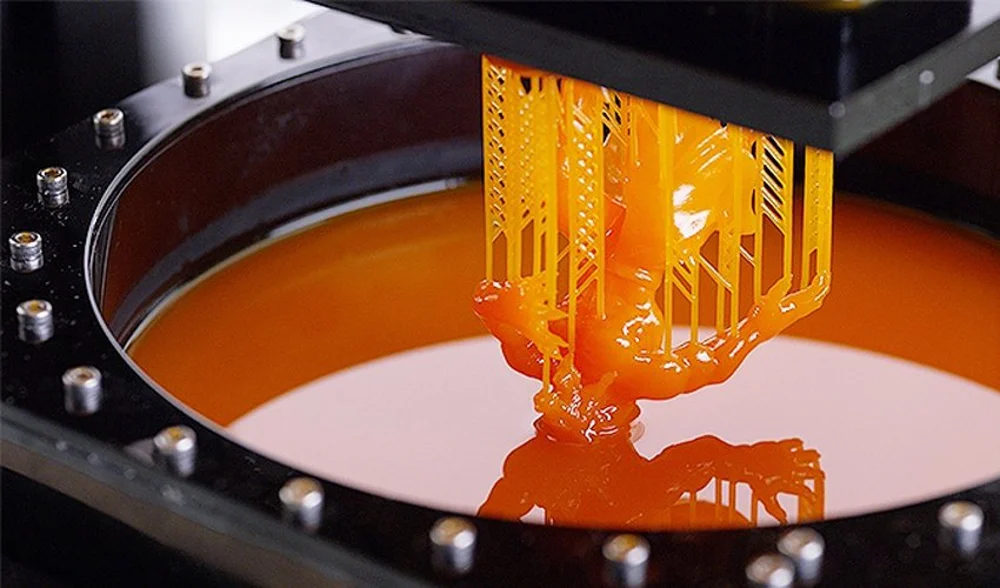

DLP stands for digital light processing, and is a type of vat polymerization. Vat polymerization 3D printing technologies make use of a (liquid) photopolymer resin which is able to cure (solidify) under a light source.

In the world of vat polymerization, there are two main technologies: SLA and DLP. Naturally, both use resin and a light source to produce parts, the main difference being the type of light source which is used to cure the resin.

In order to understand DLP properly, it first makes sense to describe its predecessor, SLA. 3D printers that employ SLA, or stereolithography, use a build platform, an elevator that moves the platform upwards, a tank filled with resin, a light source and galvanometers.

SLA 3D printers start to work by lowering the build platform into the resin-filled tank with only one layer of height left between the bottom of the tank and the build platform. Then the galvanometers take over.

Galvanometers are mirror-like components used for navigating the laser beam of an SLA printer to the bottom of the tank. With the help of G-code, galvanometers navigate the laser beam in a path which represents one layer of a certain part. The laser then cures the resin making a solid layer of a part. When one layer is complete, the build platform moves up by one layer in height and the process is repeated until the part is complete.

How Does It Work?

Now that you know how SLA works, it’s time to take a closer look at DLP. DLP is a “sister technology” to SLA as the only big difference is the light source used to cure the resin. As we just mentioned, SLA printers use lasers combined with galvanometers to cure resin.

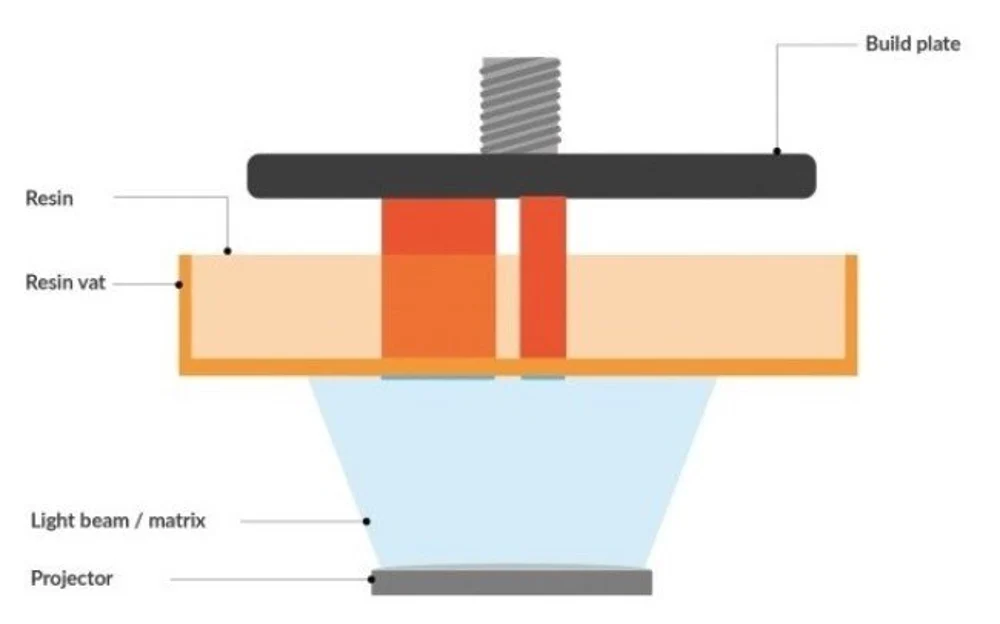

With a DLP 3D printer, the light source is a specially developed digital light projector screen. Thanks to this screen, DLP is generally considered to be faster than SLA, and here’s why:

With SLA, the laser has to individually cure the resin in a “point to point” technique. On the other hand, a DLP projector screen flashes an image of a layer all at once! Thus all points of a layer can be cured simultaneously. In this way, the print speed is increased in comparison to SLA since it takes less time to cure a single layer.

Since the DLP is a digital technology, the 2D image that is projected is composed of pixels. When translated into three dimensions, they become voxels.

The light source of a DLP 3D printer itself, an LED screen, means nothing without a digital micromirror device (DMD), the “heart” of every DLP chipset. A DMD contains hundreds of thousands or even millions of small micromirrors that direct the light and create the pattern of a layer onto the bottom of the resin tank.

The resolution of a printed part using a DLP 3D printer usually corresponds to the number of micromirrors inside a DMD device.

SLA vs DLP

Up to this point, we’ve only mentioned the benefit of a DLP 3D printer over an SLA machine: the increased speed. As you would expect, DLP also has its limitations.

Since a DLP 3D printer uses a digital projector screen, the resolution of your print directly corresponds to the resolution of your projector. In other words, a cheaper projector will likely mean reduced resolution. This is in contrast to SLA, where even cheaper devices are likely to have decent resolution (i.e. a narrow beam width).

Another limitation of DLP printers is the boxy surface finish. Since voxels are rectangular, curved sections of a print tend not have a very smooth finish when compared to SLA. The good thing is that the problem with voxels and curves can be solved by sanding the part after printing.

Both DLP and SLA printers use resins, so the cost of printing should be similar. However, keep in mind that cost greatly depends on the manufacturer of the resin or even the printer.

The Best Machines

Source: https://all3dp.com/2/what-is-a-dlp-3d-printer-3d-printing-simply-explained/