Maritime non-profit Island Missions Support has begun using a Slice Engineering hotend to produce more robust 3D printed prosthetics for amputees in isolated areas of Guatemala.

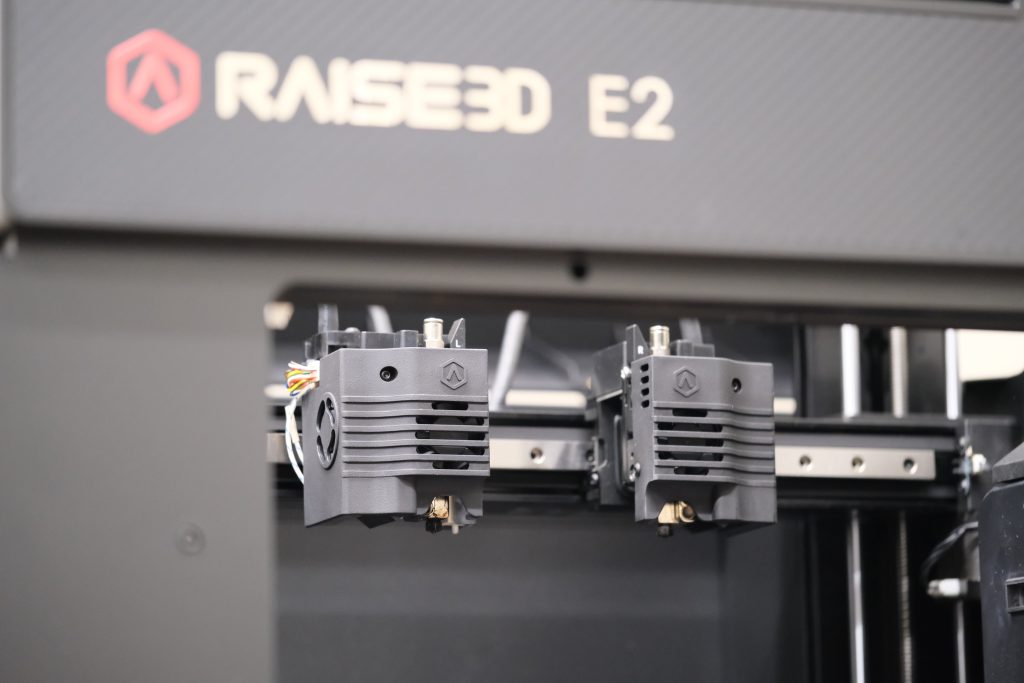

Utilizing Prusa i3 MK3S+ and Raise3D E2 3D printers, the group previously tried to create prosthetics from PETG, but the country’s hot climate caused their material to warp and prints to fail. Having upgraded the latter with a Slice Engineering Copperhead Hotend, however, the team is now able to print child and adult-sized hands and arms, which restore the ability of users to precisely grip everyday objects.

“With the Copperhead on it, I can really do a lot more with the E2,” explained Eric Lamoray, President of Island Missions Support. “The last forearm I made before our upgrade, it was a sixteen hour print, and I had to sit there and monitor it because the printer had six clogs. Now there’s not a problem, I don’t have the filament waste anymore, and the print time’s down to about twelve hours. I might even be able to push the speeds higher.”

Aiding amputees in remote areas

Working from a 46-foot sailboat in the South Pacific, Lamoray and his Island Missions Support team specialize in carrying out maritime, humanitarian and Christian missionary endeavors. On one such mission, seven months ago, Lamoray and co. were sailing to Vanuatu, transporting medics to some of the region’s most remote islands, when they were stopped in Guatemala due to COVID-19.

While there, the Island Missions Support crew saw an opportunity to help local amputees, leading Lamoray to teach himself 3D printing and set up a two-machine print farm. However, while the US Air Force veteran-turned-tinkerer’s Prusa proved capable of churning out parts, larger objects didn’t fit on its print bed, and as with his Raise3D E2, material warpage under heat affected prosthetic durability.

To get around these issues, Lamoray reached out to Sliced Engineering, which hooked him up with a Raise3D E2 Upgrade Bundle that now enables Island Missions Support to 3D print artificial PETG and nylon arm parts effectively. With the upgrade, the team are also able to 50% print faster due to reduced nozzle-clogging, and build parts out of Atomic Filaments, in colors his patients have long been requesting.

Over the course of five months, the team managed to use its new and improved system to 3D print 28 prosthetics and Lamorary says that if anything, order volume is picking up. With this in mind, Island Missions Support is expanding its operations with a third system. The group has also branched out into braille teaching tools for the blind, and is looking into the potential of 3D printing prosthetic legs, due to the high number of amputations caused by motorcycle accidents in Guatemala.

As well as helping those victims of accidents or illnesses like diabetes, the group tries to address the needs of patients born with physical deformities. In one such case, Lamoray says they helped a young man who used to hide his missing hand in his pocket, but he now sports a new prosthetic, which has turned him into a “confident outgoing young man” that’s better capable of providing for his family.

“To see the difference mentally as well as physically and emotionally is just amazing,” explained Lamoray. “With 3D printing, it’s incredible what we can do. The technology’s really moving fast, so it’s going to be really interesting to see where we are machine and materials-wise in one or two years’ time.”

Given that children tend to outgrow their prosthetics around once a year, Lamoray believes the project is likely to be a “lifetime commitment.” That said, if locals were able to take over the initiative themselves, the ex-serviceman says he’d like to take Island Missions Support to other countries like Belize and Honduras, where he says amputees also need support.

Manufacturing on Demand

Moving forwards, the organization plans to move into 3D printing above-elbow prosthetics as well. At present, Island Missions Support’s artificial limbs are held together with orthodontic band hinges and feature fingers with silicon fingertips, actuated by an 80 lbs spectra fishing line.

While it remains easier and cheaper to ship these tips in, Lemoray and his team are now 3D printing their first prosthetic fingers, as they seek to expand their efforts to meet the needs of amputees in the developing world.

“We hope to get at least one more 3D printer, as I see the volume picking up,” concluded Lamoray. “From my understanding, the unmet prosthetic need in the third world is about 1.5 million. I can’t begin to meet all of that, but I can address what is here and what’s local. I’ve seen that very often, small local organizations do more permanent help.”

Accessorizing with Slice Engineering

Based in Florida, Slice Engineering is a developer of 3D printing accessories that specializes in helping makers overcome the issues preventing them turning design concepts into reality, and the team says its “insatiable desire to improve the world,” has seen it come up with ways of 3D printing “faster, at higher resolution, using engineering-grade plastics.”

Through these efforts, Slice Engineering has amassed a portfolio of third-party 3D printers and ancillaries, including nozzles, extruders, filaments and spare parts, as well as a range of proprietary hotends. In the case of the latter, this offering is broadly dominated by two product types: the Slice Engineering Mosquito Hotend and the Copperhead.

Both feature a ‘RepRap-style’ nozzle, in that they measure 12.5 mm in length and have a 7mm thread length, but they also enable the extrusion of filament at temperatures of up to 500 °C and 450 °C respectively. This is made possible by the products’ Bimetallic Heat Break technology, which allows users to overcome the nozzle reliability, heat creep and jamming issues that cause costly print fails.

In order to figure out which of the firm’s ancillaries is best for their 3D printer, makers can deploy Slice Engineering’s Shop By Printer Tool, which instantly matches them with the upgrade they need. More broadly, the company also works with partners, with the goal of continually developing new solutions to everyday 3D printing problems. Those interested in finding out more about working with the business, either as an OEM or reseller, can head over to the Slice Engineering Partner Portal

.

You might also like:

Prellis Biologics hires new CEO, raises $35M towards 3D bioprinted lymph node R&D : Raised via a Series C funding round led by Celesta Capital and Avidity Partners, and backed by Khosla Ventures, SOSV, True Ventures and Lucas Venture Group, the cash will be used to expand Prellis Biologics’ plans for its Externalized Human Immune System (EXIS), an immune system in a dish that replicates cell-to-cell responses.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paul Hanaphy

Leave A Comment