Leading sand and metal binder jet 3D printer manufacturer ExOne and the University of Pittsburgh are working together to develop reusable metal filters that fit into plastic respirator cartridges.

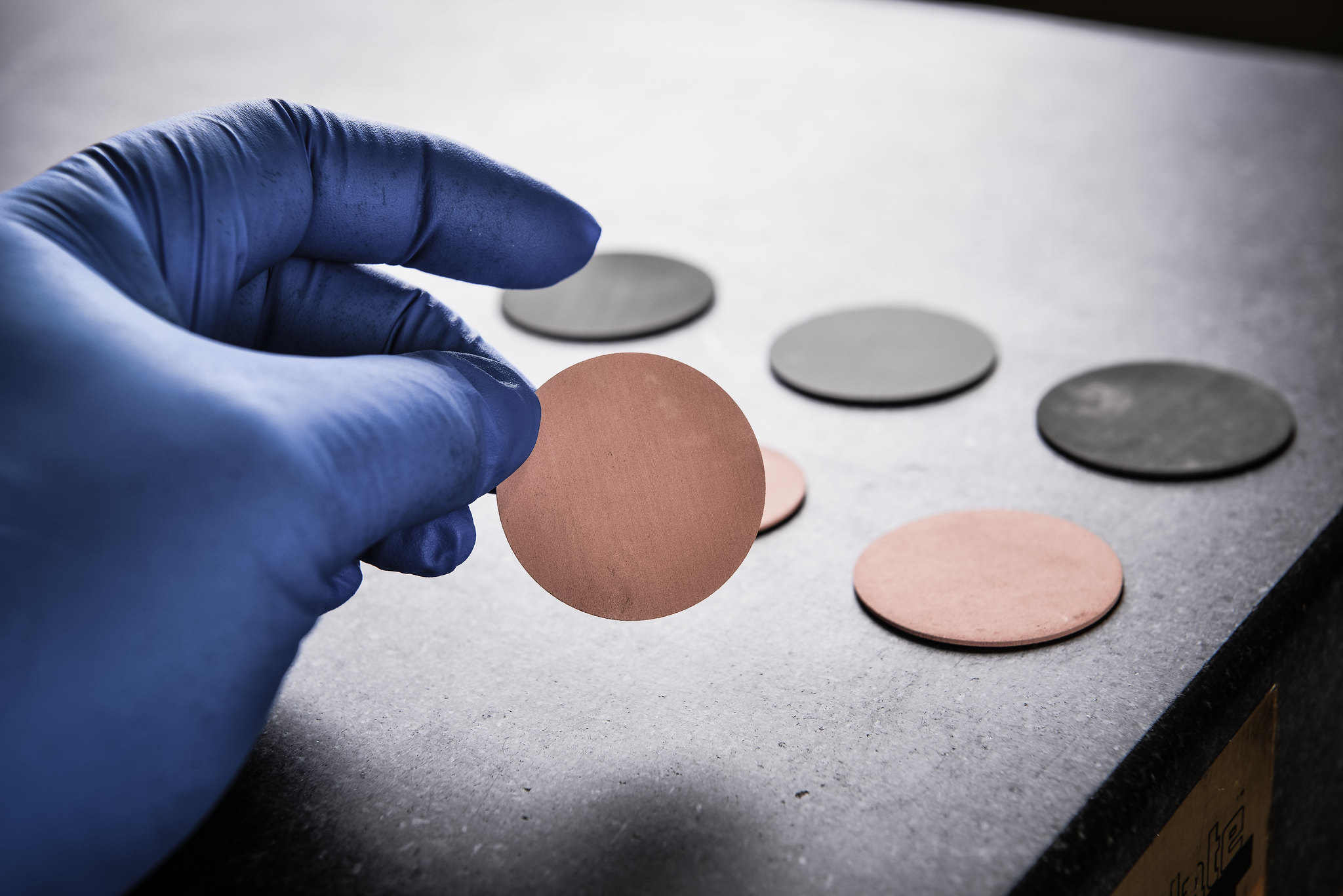

ExOne’s binder jetting 3D printing process can be used to produce metal parts with specific porosity levels that can effectively filter out contaminants while allowing airflow. Leveraging its technology, the company was able to develop reusable and porous metal filters in two metals: copper and 316L stainless steel. The plastic respirator cartridge was designed by the Mechanical Engineering & Materials Science department in Pitt University’s Swanson School of Engineering.

The initial tests for airflow and filtration efficiency are currently underway, and the filters are being optimized with the objective of adhering to an N95 respirator standard. ExOne explains that the combined units can potentially deliver sustainable, sterilizable personal protection equipment (PPE) for long-term use against contaminants such as COVID-19, the disease responsible for the current Coronavirus pandemic.

“Our team has been working urgently to expedite this promising and reusable solution for medical personnel on the frontlines of fighting the COVID-19 pandemic,” said John Hartner, ExOne CEO. “Our customers routinely print porous metal filters for a variety of purposes, and we are confident that we’ll have a solution soon that can enable medical personnel to sterilize metal filters for repeated reuse, eliminating waste.”

“Once approved, we can print these filters in a variety of sizes for respirators, ventilators, anesthesia masks or other equipment.”

Creating different porosity levels for different 3D printed metal filters

ExOne’s binder jetting technology works using a printhead to selectively deposit liquid binder layer-by-layer onto a thin coating of metal powder, until a final object is formed. Once this item has been 3D printed from the powdered metal, it is then sintered in a furnace.

Typically, binder jetted metal parts are sintered to full density. However, ExOne’s technology allows for a specific level of porosity to be established for the object in question, in this case, a metal filter. The required level of porosity for filters, however, would differ between different metal materials.

As such, to test filters in different metals and porosities, a research group led by Dr. Markus Chmielus, Associate Professor of Mechanical Engineering and Materials Science at the Swanson School, is using CT scanners to analyze their microstructure and porosity. To help analyze and optimize the performance of the filters, additional computer simulation support is being provided by engineering simulation software developer Ansys.

“The advantage of binder jet 3D printing over other additive manufacturing methods for this filter application is the ability to utilize the porosity of the printed part and then fine-tune it during the high-temperature densification or sintering process to achieve optimum filtering and airflow performance,” explains Dr. Chmielus.

Manufacturing on Demand

While both copper and stainless steel filters have been 3D printed by ExOne, and are currently being tested by Pitt University, copper itself has been known to possess antibacterial properties for quite some time, according to ExOne. The company explains that the first recorded use of copper to kill germs was in the Edwin Smith Papyrus, the oldest known medical document in history, according to the Smithsonian. Additionally, many studies have proven copper’s disinfectant powers, including one in 2015 which, funded by the U.S. Department of Defense, revealed that copper alloys contributed to a 58 percent reduction in infections.

ExOne’s metal binder jetting 3D printing technology

ExOne developed the first iteration of their binder jetting technology in 1996, which it has since adopted for its sand and metal 3D printing systems. It’s selection of metal 3D printers includes the Innovent+, an entry-level system designed for R&D and small part production. At Formnext 2018, the company introduced its X1 25 PRO system, which was designed to enable a larger build volume and the equivalent powder metallurgy capabilities powders from the Innovent+.

Around a year later in November 2019, the company launched the X1 160PRO. The company’s largest machine to date, it has been developed for high volume, large scale production of end-use parts and castings.

Additionally, ExOne has engaged in a number of partnerships to develop its metal binder jetting technology. Last year it announced a collaboration with Sandvik Additive Manufacturing to advance its binder jet 3D printing process. Both companies will work towards optimizing the use of metal powders with binder jet 3D printing.

The company is also working with Oak Ridge National Laboratory (ORNL) to advance binder jet 3D printing to enable the 3D processing of H13 Tool Steel.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Anas Essop

Leave A Comment