Just because a 3D printer has “high resolution” in the printer specifications doesn’t mean your 3D printed parts will be accurate or precise.

Understanding the meaning of accuracy, precision, and tolerance is imperative for achieving meaningful 3D print performance for any application. In this post, we’ll parse through what these terms mean and how to think about them in the context of 3D printing.

Defining Accuracy, Precision, and Tolerance

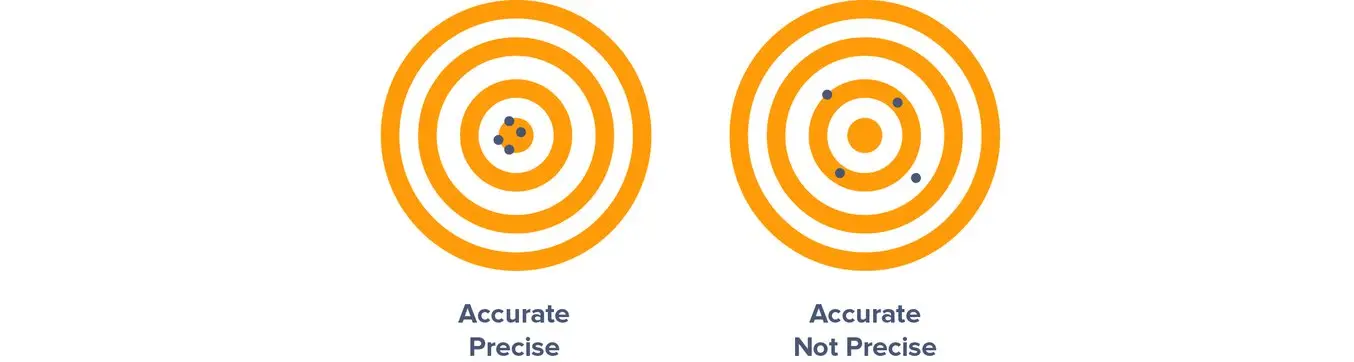

Let’s start with definitions: What’s the difference between accuracy, precision, and tolerance? For each term, we’ll use a target—a common example for unpacking these concepts—to help visualize meaning.

Accuracy

Accuracy is how close a measurement is to true value. In the case of a target, true value is the bullseye. The closer you are to hitting the bullseye, the more accurate your shot. In the world of 3D printing, true value equals the dimensions you design in CAD. How closely does the 3D print line up to the digital design?

Precision

Precision measures the repeatability of a measurement—how consistent are your shots at the target? Precision measures this consistency only; your shots could be hitting near the same spot every time, but that spot doesn’t have to be the bullseye. In 3D printing, this ultimately translates to reliability; can you rely on your machine to produce your expected results for every print?

Tolerance

Exactly how precise do you need to be? That’s defined by tolerance, and tolerance is defined by you. How much wiggle room do you have in your application? What’s an acceptable variance in the closeness to the measurement that precision is hitting? That will depend on your project, for example, a component with a dynamic mechanical assembly will require tighter tolerances than something like a simple plastic enclosure.

If you’re defining a tolerance, you’ll likely want accuracy too, so let’s assume we’re measuring precision of shooting at the bullseye. Earlier, we defined the shots on the target pictured on the right as not precise.

However, if your tolerance range is fairly wide, it may be okay. The shots aren’t as close to each other as in the target on the left, but if the acceptable range of precision is the distance of ±2.5 rings, then you’re within spec.

Generally, achieving and holding tighter tolerances means higher manufacturing costs and quality assurance.

How to Understand Accuracy and Precision in 3D Printing

There are a variety of factors to consider when thinking about accuracy and precision in 3D printing, but it’s also important to identify your specific needs.

For example, a precise-but-inaccurate 3D printer may be the best choice for some applications. A low-cost fused deposition modeling (FDM) machine will produce less accurate parts, but for an educator teaching students about 3D printing for the first time, it may not be important for the model to exactly match a student’s CAD design.

However, knowing that the printer will consistently work as promised and produce the quality expected from it, within the tolerances the user is used to, could be crucial to a successful experience.

Read our in-depth guide about FDM vs. SLA 3D printers to learn how they compare in terms of print quality, materials, applications, workflow, speed, costs, and more.

Here are four big factors at play in determining the accuracy and precision of a 3D printer:

3D Printing Technology

3D printing is an additive process, so parts are built layer by layer. Each layer introduces an opportunity for inaccuracy, and the process by which layers are formed affects the level of precision, or repeatability, of the accuracy of each layer. For example, in FDM 3D printing, layers are extruded by a nozzle, which lacks the control and ability to achieve intricate details that other 3D printing processes can offer.

In stereolithography (SLA) 3D printing, liquid resin material is cured by a highly-precise laser to form each layer, which can achieve much finer details and is more reliable to repeatedly achieve high quality results.

Similarly, selective laser sintering (SLS) 3D printing relies on the precision of a laser to fuse nylon powder into solid parts.

3D printer specs alone do not represent final dimensional accuracy. One common misrepresentation of accuracy for various 3D printing technologies is the descriptions of XY resolution as dimensional accuracy.

For digital light processing (DLP) printers, XY resolution is the projected pixel size. Many 3D printer systems use this projected pixel size, or XY resolution as the overall accuracy figure—for example, taking a 75 micron projected pixel size and asserting that the accuracy of the machine is ±75 microns.

Check out our guide about SLA vs. DLP 3D printing where we walk through the details of the two resin 3D printing processes and explore how they compare.

However, this data has no implications for how accurate a printed part will be. There are many sources of error that still have an impact on accuracy, from components, to calibration, to the next two we’ll cover: materials and post-processing.

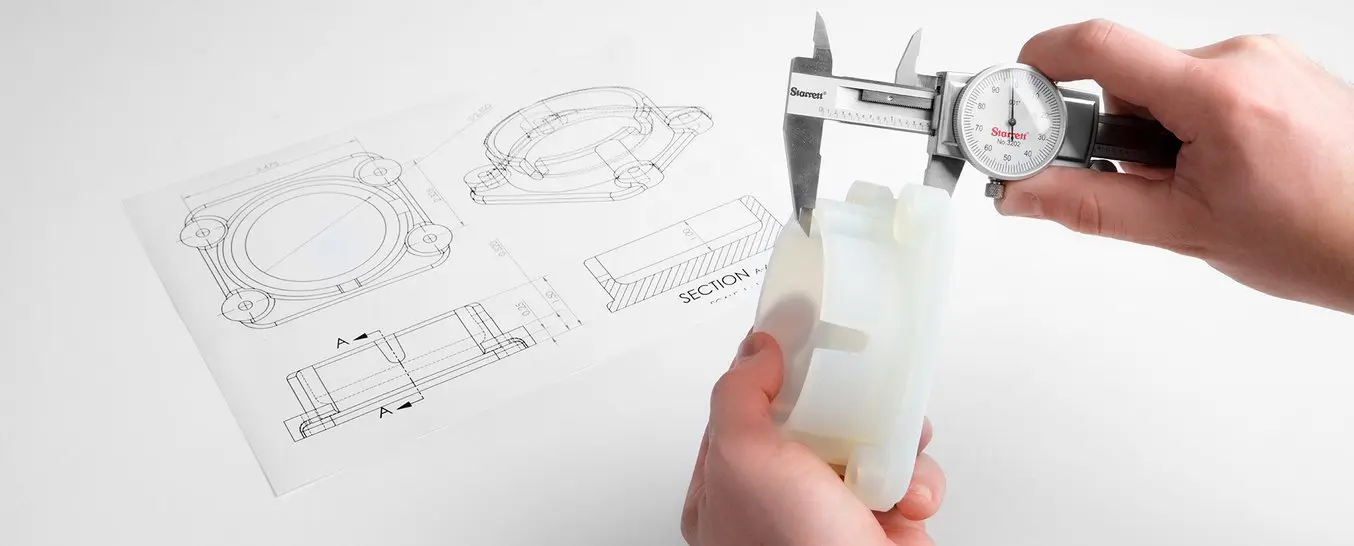

Ultimately, the best way to evaluate a 3D printer is to inspect real parts.

Materials

Accuracy may also vary depending on which materials you use to print, and the mechanical properties of those materials, which can also affect how likely a print is to warp.

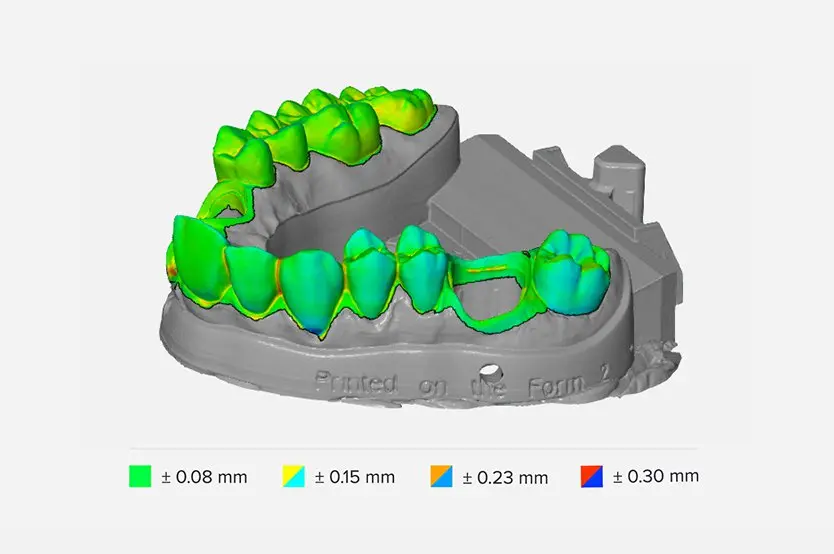

Again, it all depends on your application. For example, in dental 3D printing, accuracy is crucial. If you’re printing a concept model, however, your goal may be just to get a general sense for a physical product, and accuracy will be less important.

Post-Curing

Often, parts will need to be post-cured after 3D printing, and post-curing causes shrinkage. This is normal for any parts produced with resin-based SLA or DLP 3D printing processes, and may need to be considered in designs depending on the printer. PreForm, Formlabs’ free print file preparation software, automatically compensates for this shrinkage to ensure post-cured prints are dimensionally accurate to the original CAD designs.

How does post-curing work? Learn more about the science behind the process, and find effective techniques for successfully post-curing SLA 3D prints.

Ecosystem

Achieving a successful 3D print requires attention to more than the printer itself, and consideration for the entire process.

The print preparation software, materials, and post-processing tools can all contribute to final results. Overall, integrated systems that are designed to work together produce more reliable results.

Tolerancing in 3D Printing

Unlike machining, where parts are progressively refined to tighter tolerances, 3D printing has a single automated production step. While complex surfacing adds costs to a process like CNC milling, complexity in 3D printing is essentially free, though the tolerances of a 3D printed part can’t be automatically refined beyond what the printer can produce without resorting to subtractive methods.

3D printing is great option if you have gross complexity like undercuts and complex surfaces, and don’t necessarily need higher surface precision than ±0.005 in (standard machining). Tolerances beyond standard machining have to be reached subtractively, either through hand finishing or machining, in both 3D printed parts and CNC parts.

SLA has the highest tolerance of commercially available 3D printing technologies. Compared to machined accuracy, SLA 3D printing tolerance is somewhere between standard machining and fine machining.

Generally, more compliant SLA materials will have a wider tolerance zone than more rigid materials. When printing parts for assemblies specifically, designing for proper tolerance and fit lowers post-processing time and ease of assembly, and reduces the material cost of iteration.

Learn More About 3D Printers

There are tons of other attributes to consider when evaluating 3D printers–do your parts need to be isotropic? What mechanical properties do your parts (and therefore, materials) require? One of the best ways to get started is to see real printed parts. Choose a free sample from Formlabs in a variety of materials to see SLA quality for yourself.