Moisture from the air can easily ruin your 3D printer filament, meaning it can also ruin your prints! Here’s how to dry filament.

Filament vs. Moisture

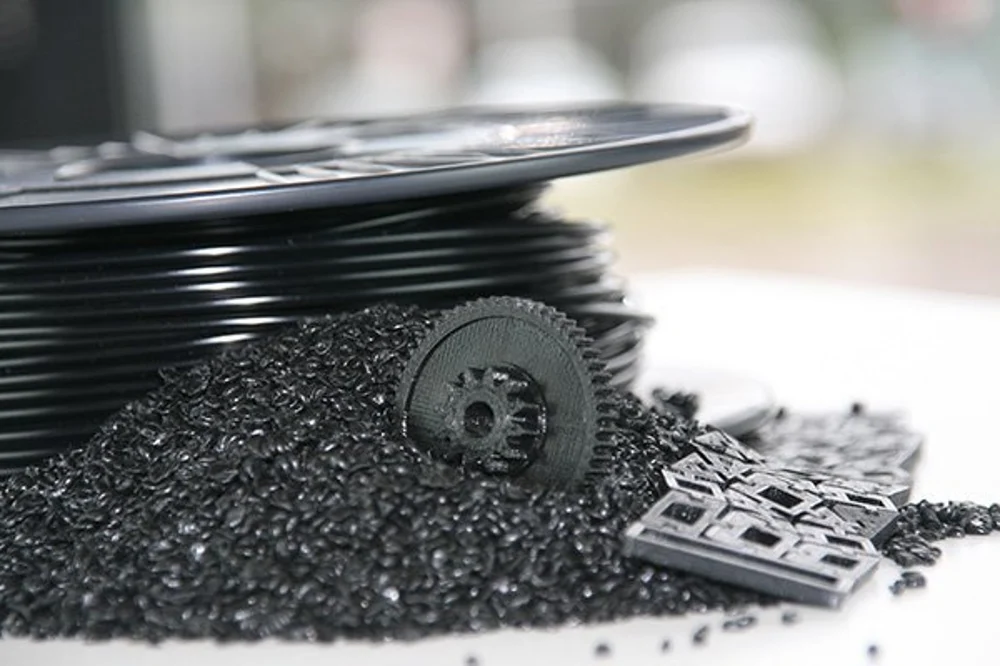

All FDM 3D printing filaments are hygroscopic. That’s a fancy way of saying that the material likes to absorb moisture.

This hygroscopicity can wreak havoc on 3D printing filaments. As plastic polymers, they’re made of chains of molecules strung together. Moisture introduces water molecules that break up these chains, ruining the plastic and causing a whole slew of problems while printing.

But don’t fret. “Wet” spools of filament are easily saved, and proper storage can prevent future mishaps.

In this article, we’ll look at how to identify wet filament, how to dry it, and finally, how to store the moisture-free result.

Identifying Wet Filament

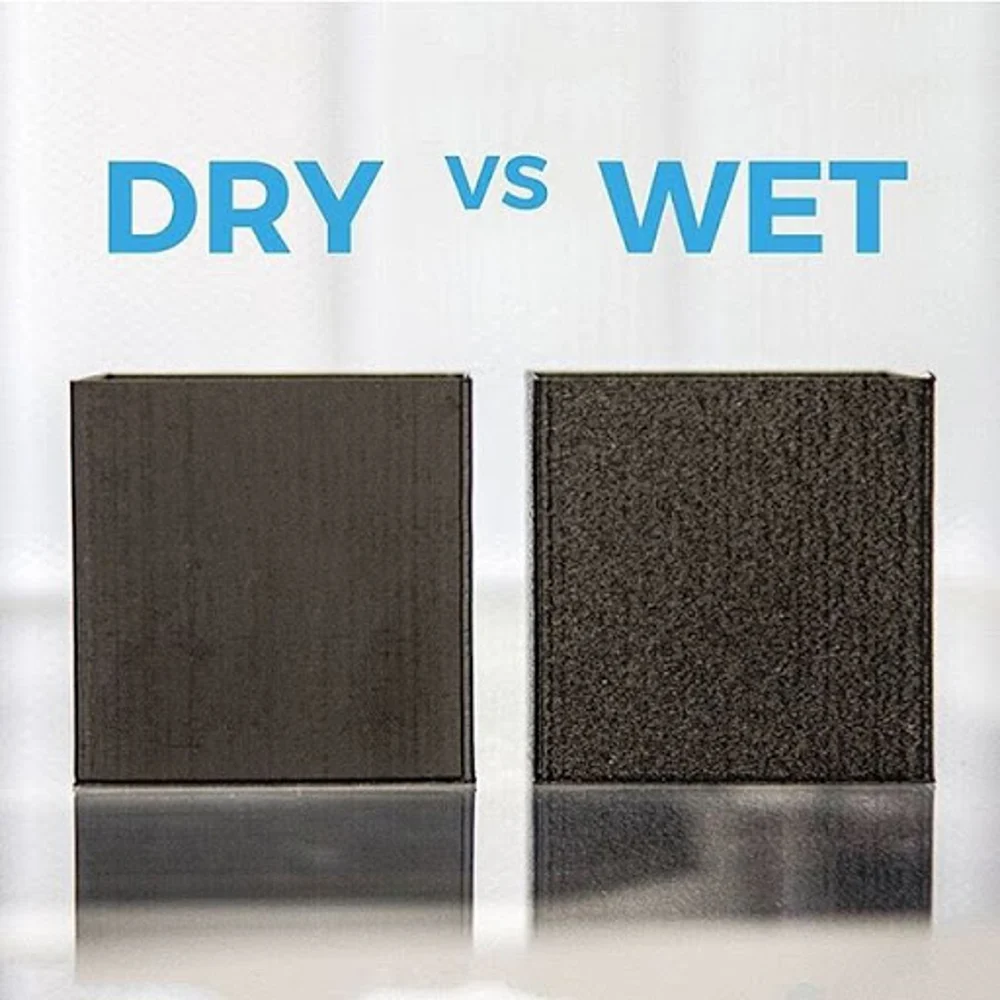

Different filaments absorb moisture at different rates, but there are a few common signs that you’ve got a wet spool:

- Popping or cracking sounds when extruding

- Severely reduced part strength and layer adhesion

- Uneven extrusion lines

- Uncharacteristically severe stringing, blobbing, or oozing

- Uncharacteristically textured or “fuzzy” surfaces on prints

If you’re seeing any of the above symptoms, it’s probably a good idea to dry out your filament. With especially hygroscopic materials like nylon, PETG, PVA, and flexibles, symptoms may appear after just one night left out in the open.

Dry out wet filament as soon as you identify it to preserve print strength and quality.

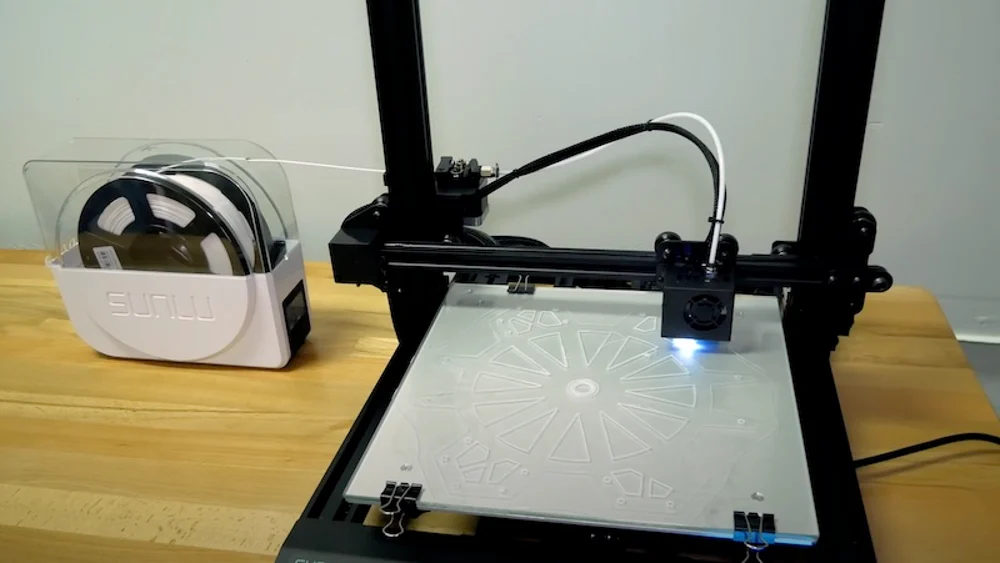

Method #1: Filament Dryer

In case you didn’t already know, there are specific devices dedicated to the task of drying filament! If you want something designed for the purpose, this may be your best option.

There are various types of filament dryers that use various methods of drying, but they’re all fairly simple to operate. In essence, you put your spool inside, select the correct setting, and let the dryer do its thing.

After some predetermined amount of time, you can retrieve your spool, which should have been freed of moisture. In some cases, the dryer works alongside the printer, allowing you to save time and hassle by drying and printing at the same time.

These machines offer a more reliable and fine-tuned drying experience, which lets you forget about filament issues and focus on tuning your printer to get those prints just right. And, your oven remains free for cooking a cake to celebrate your freshly de-moisturized collection of printing material!

Method #2: Oven

Probably the easiest and most common way of drying filament is throwing it in the oven. Just set the temperature to right below the glass transition temperature of the plastic, and leave it in there for four to six hours for the moisture to evaporate. The longer you leave it, the drier it’ll get.

- PLA: 40-45 °C

- ABS: ~80 °C

- Nylon: ~80 °C

Important note: Wait until your oven reaches the target temperature before placing the spool in. All ovens slightly overshoot the target temperature when heating up, so placing your spool in early may soften the plastic and fuse parts of the filament together.

You also want to make sure that your oven is capable of accurately holding the temperatures listed above. If not, you run the risk of melting all the plastic and fusing your entire spool together.

Method #3: Food Dehydrator

Food dehydrators are also great tools for drying out filament, especially if you don’t have a nice oven. Originally designed for drying fruit, dehydrators are designed to operate at lower temperatures than ovens and are therefore easily repurposed for drying filament.

- PLA: 40-45 °C

- ABS: ~80 °C (or highest available temperature)

- Nylon: ~80 °C (or highest available temperature)

At low prices, they can be found all over the Internet. Usually, they come with removable layers and meshing that you can add or remove to fit your spools.

Proper Storage of Dry Filament

Now that your filament is dry, you’ll want to keep it that way for as long as possible. To do that, store dry spools in a humidity-controlled environment. This can range anywhere from an airtight box with desiccant packs to dedicated commercial solutions. Usually, the former is more than enough, but use what suits your needs.

Just keep in mind that proper storage can’t dry filament for you; it can only preserve it. If your filament becomes wet again, you’ll have to re-dry it with the methods described above.