In the production of casts, sand casting is a commonly used process. Casting is one of the metal processing methods. It is a metal processing method in which liquid metal is poured into a casting cavity suitable for the shape of the part, and after it is cooled and solidified, a metal green part with a certain shape, size and performance is obtained.

However, the more complex the structure of the casting, the more troublesome the shaping of the mold. When we apply rapid prototyping technology into sand casting, the difficulties related to the shape and structure of the casts disappear. This valuable technical feature makes 3D printing outstanding to adapt to the competitive environment of the contemporary manufacturing market and develop rapidly.

The benefits of 3D printing

The traditional sand mold manufacturing process is generally: CAD design → process simulation → mold making → tooling and fixture manufacturing → sand mold manufacturing → casting.

After using 3D printing, the process is simplified: CAD design → process simulation → 3D printing sand mold → casting.

It used to take a one-month cycle, but now it can be completed in just a few days, which greatly shortens the production cycle and saves a lot of manual work.

As for the production of casting molds and cores, rapid prototyping technology only requires 30%-50% of the labor hours and 20%-35% of the cost compared to traditional processing methods.

3D printing prototypes have been widely used in the fields of machinery, electronics, automobiles, aviation, and aerospace. With the improvement of this technology, it has brought a revolution to the casting industry.

- 3D printing technology does not require any special auxiliary tools.

- It is not limited by the batch size.

- It can be directly converted from a CAD model to a 3D solid model.

- The product cost has almost no relation with the complexity of the parts.

- It is especially suitable for complex, parts with fine internal structure.

- The manufacturing flexibility is extremely high, one machine can be used to produce parts of various shapes.

Applications of Rapid Prototyping

Rapid prototyping of casting molds can cover applications of sand casting, investment casting, ceramic precision casting, and plaster precision casting.

Direct 3D printing of sand molds eliminates the need for the traditional molding process, and accurately controls the forming of materials according to the geometric information. The gating system can be also produced at the same time.

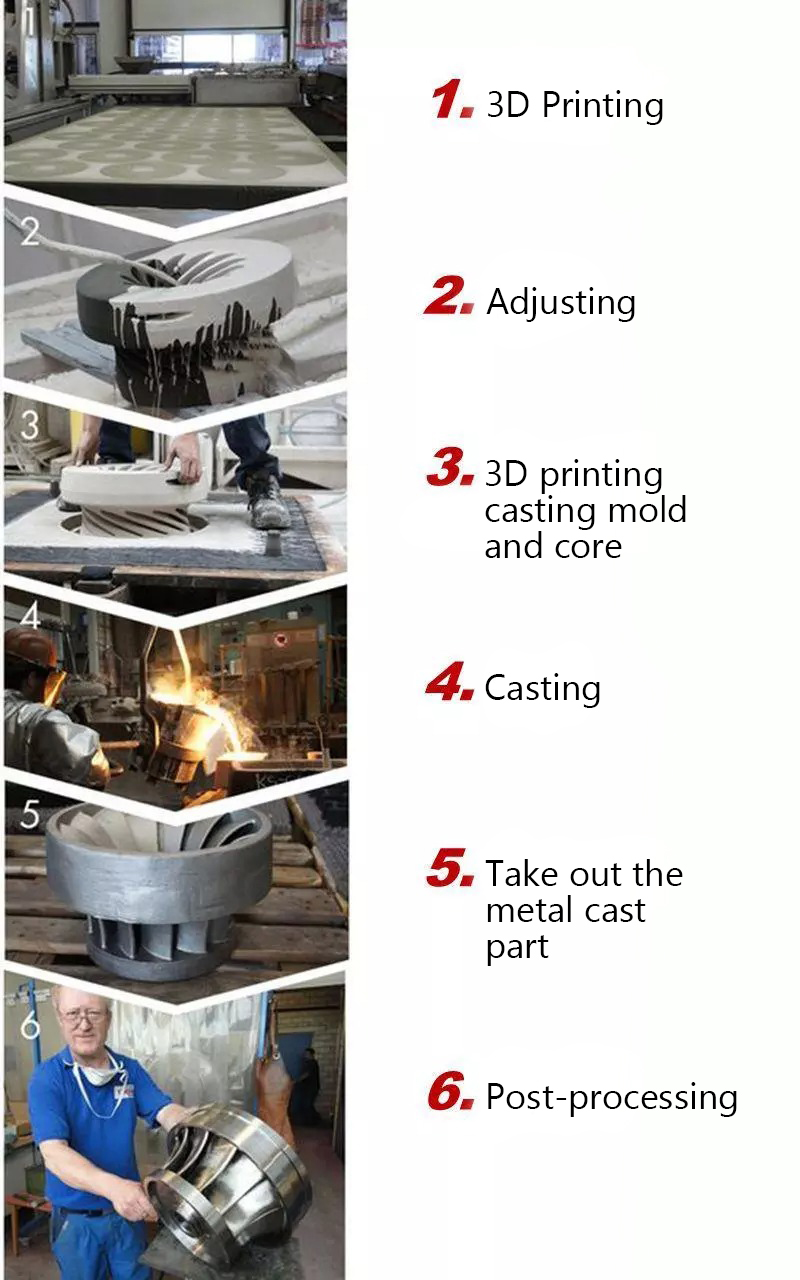

How to combine casting and 3D printing?

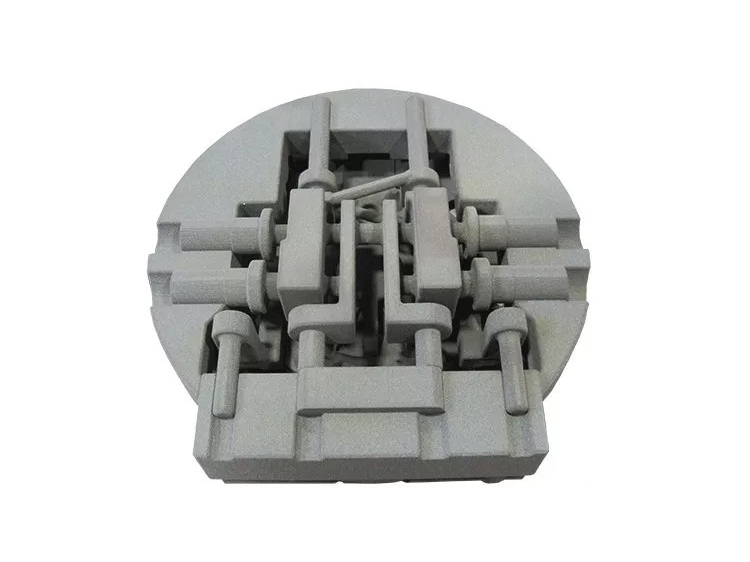

The mold for industrial parts is made up of a whole set of assembly splicing and assembly. All of them can be processed with 3D printing.

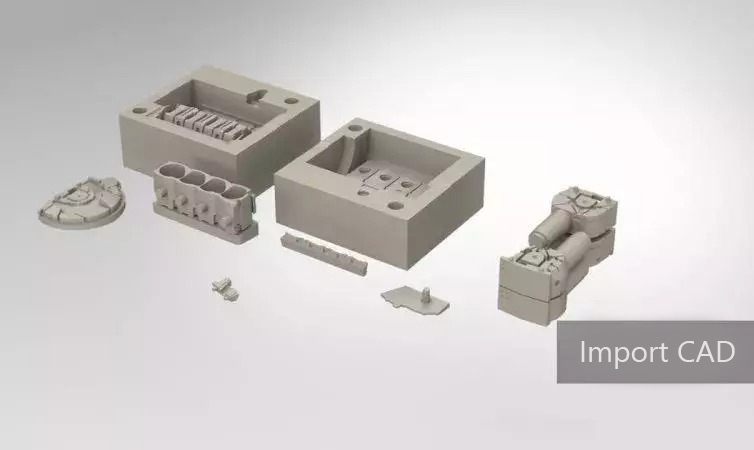

In the CAD file we import into the 3D printer, a whole set of molds is laid flatly on the printing platform in this way.

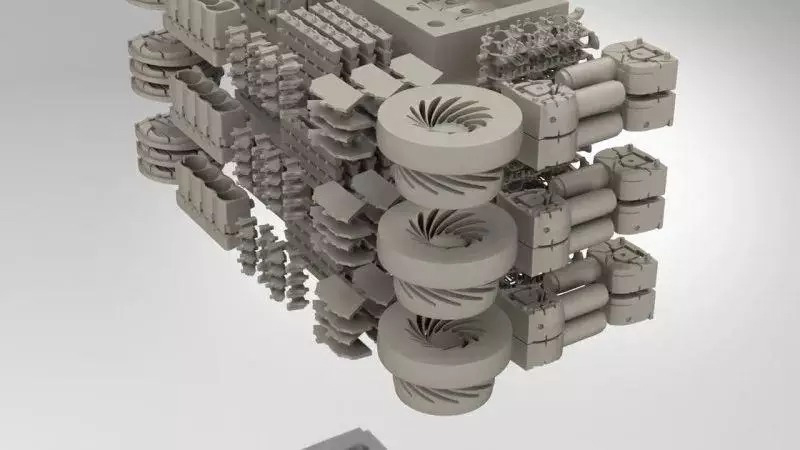

To improve the utilization of the 3D printer and save costs, engineers will edit the file and pack the models before printing.

Unlike common desktop 3D printers, a sand 3D printer is quite large, so it can only be seen in the factory.

The build volume of the printer we use is 2*1*1m.

The process of sand 3D printing is to first spread a layer of sand, cure it with an adhesive, and then stack them layer by layer. The material of the sand mold is quartz sand.

The layer thickness of the sand material can be as thin as only 300 microns (the thickness of three human hair strands).

After printing is completed, cleaning and other post-processing are required.

Case

Let’s take the production of an industrial turbine part as an example.

In the third step, we sometimes combine 3D printing molds and traditional mold-making techniques.

Because a set of molds is often composed of a cast core and a cast mold, the structure of the cast core is more complicated, and the outer cast mold is relatively simple. Therefore, due to cost considerations, many manufacturers only use 3D printing to make cast cores, and the cast molds are still manufactured by traditional techniques. Of course, the mold can be printed and manufactured directly as well.

Below are other cases made with sand 3D printing.

Conclusion

In a word, 3D printing has eliminated much of the tedium of the 3,000-year-old sand casting process. Higher volumes and relatively simple tooling are still produced using traditional manufacturing methods—milling, turning, and EDM—while everything else is sent to one of the company’s 3D printers. But the balance is steadily shifting to printing.

We have known there are so many advantages that 3D printing can bring to casting.

- Save time: short production cycle

- Cost-saving: build without tools

- High flexibility for quantity, design, and modification

- Almost any complex geometric shape

- The complex core can be built as a whole and accurately

- Print size varies from small parts to 2000 x 1000 x 1000 mm

- Compared with traditional mold making, there are no storage and maintenance costs

- Combination with traditional craftsmanships and other techniques

- Support reverse engineering

But also, it has some drawbacks. For instance, the surface finish on a 3D-printed mold generally is not as good as one made from a traditional pattern. And with traditional tooling, the cost of patterns and core boxes can be amortized, allowing for a relatively rapid reduction in per-part cost as volumes climb. With 3D printing, on the other hand, the cost per part is fairly fixed according to the volume of printed sand, so the economies of scale do not yet apply.