3D printing technology has brought about extensive changes as a new generation of design and production. Especially in the jewelry industry, the combination of wax spray 3D printing technology and paraffin casting technology has been widely used in complex and unique jewelry casting.

Two main 3D printers used in the jewelry industry

Jewelry wax 3D printer

Jewelry wax 3D printer has been available in the early 1990s, but 3D printers and materials were expensive at that time, and the performance of printing materials was poor, there has been no major development in the field of jewelry.

Nowadays, the jewelry wax 3D printer has been widely used. Using a jewelry wax 3D printer to make samples can accelerate the R&D process and saves costs than traditional hand-carved wax or hand-made silver modeling process.

However, after entering the mass production process, it returns to the traditional production process. 3D jewelry digital technology is more like a research aid. It is not a substitute for large-scale applications, nor is it used in traditional jewelry retail.

Jewelry metal 3D printer

Although the technology of 3D metal printers has matured, 3D metal printers are still very expensive. 3D metal printers for jewelry especially require high accuracy, the manufacturing price will be more expensive, coupled with high processing costs of precious metal powders like gold, and large losses are inevitable in the printing process. In consequence, 3D metal printers have not been applied to the production of the jewelry industry.

5 Steps of using the lost-wax method to print a jewelry

The advantages of 3D printing technology such as little limitation and high precision have not been fully utilized. The main reason is that 3D printing technology is only used to replace the traditional manual model-making. Here we are sharing our basic steps of printing jewelry.

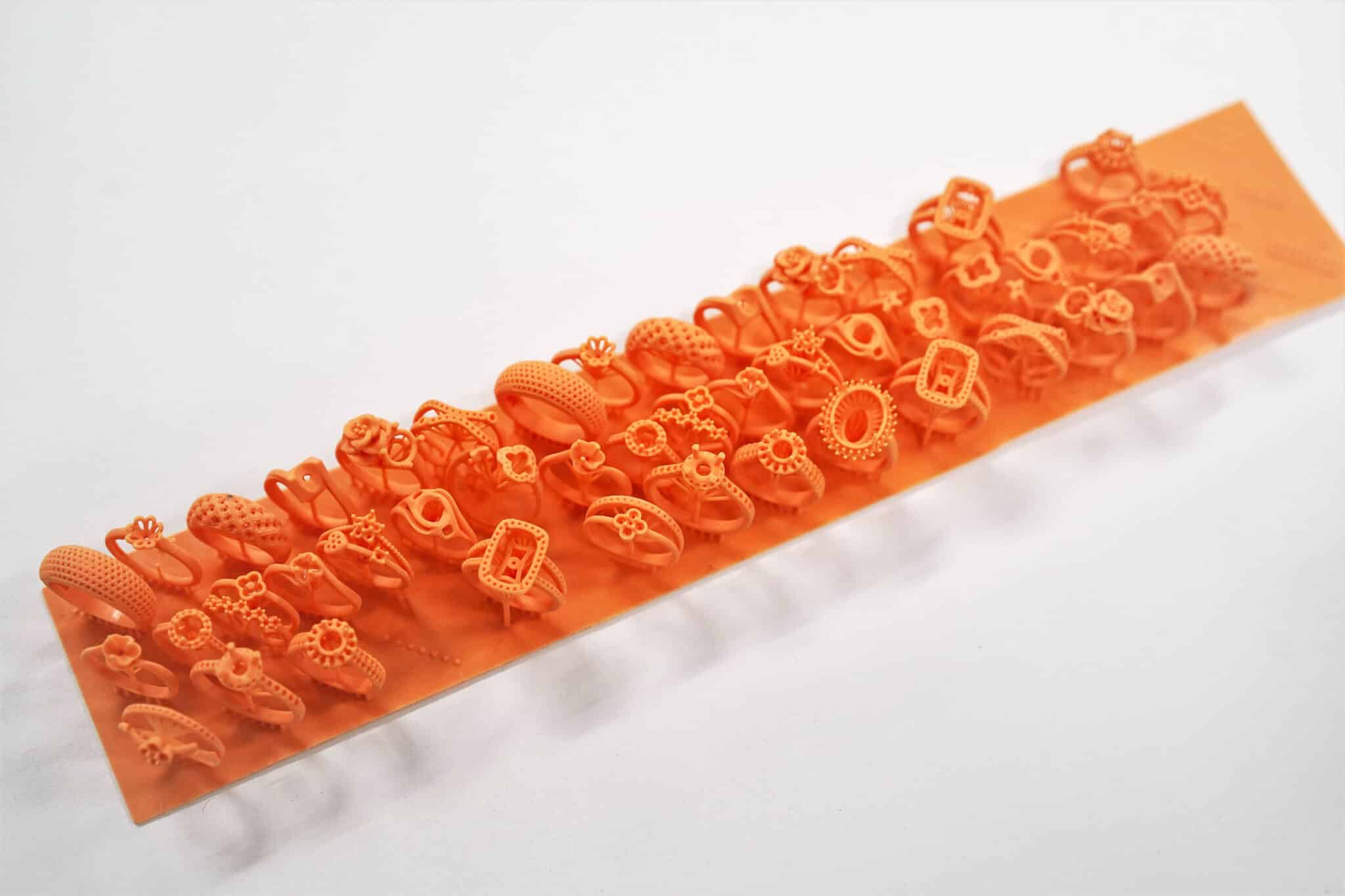

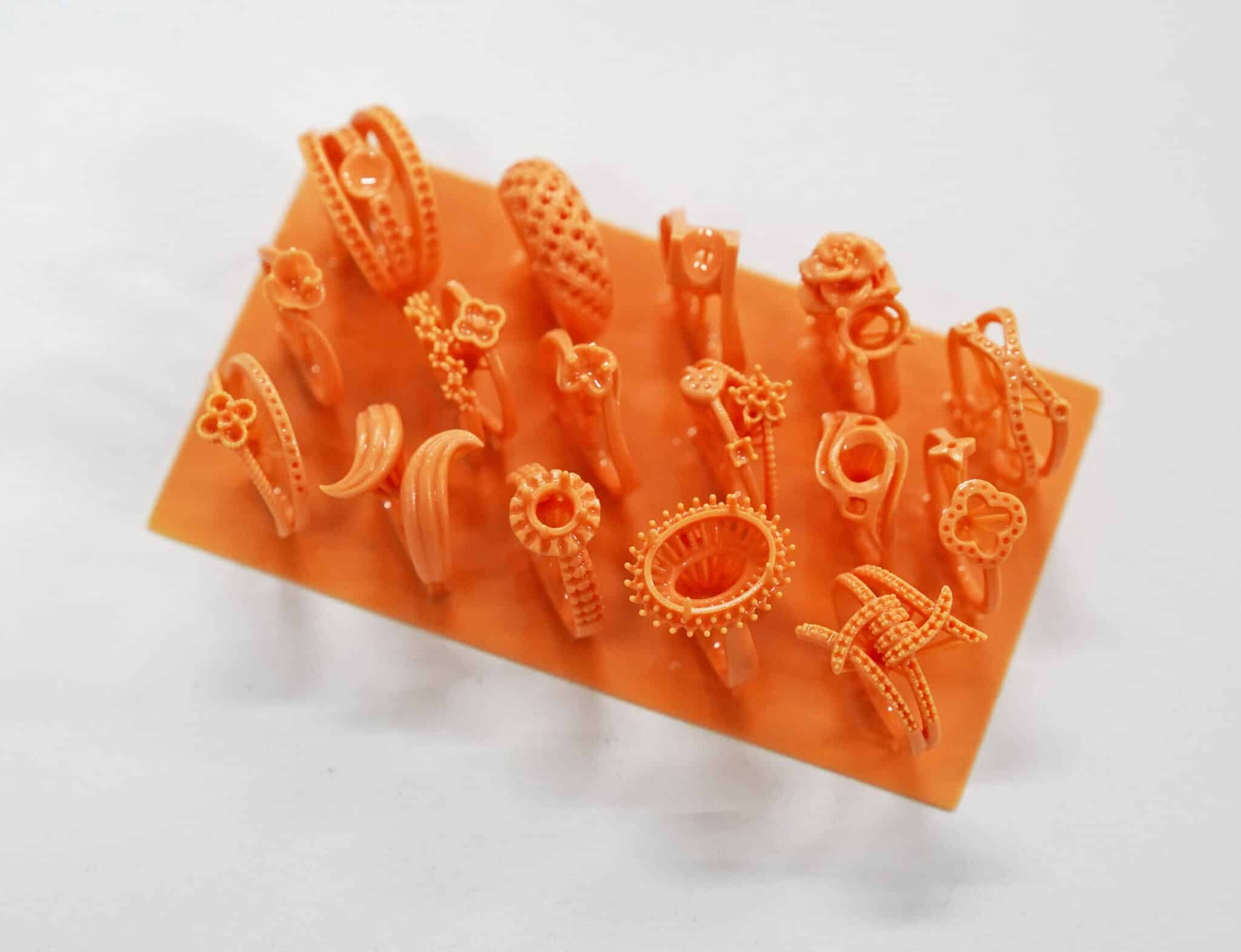

- Use a high-precision 3D printer to print the design into a wax model.

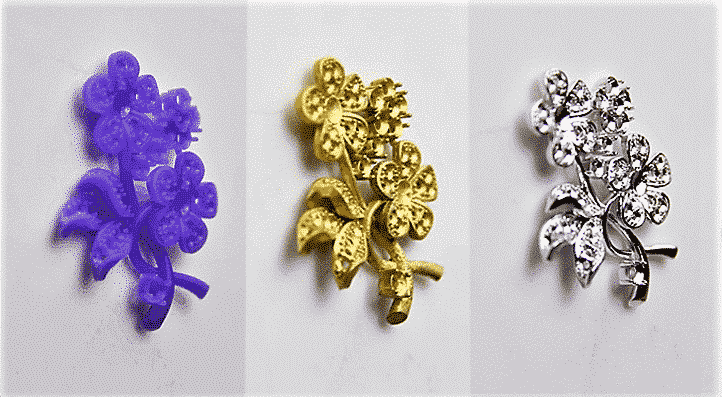

The density and surface characteristics of this wax pattern are similar to those of traditional casting wax, and are modeled and printed using multi-jet design. The printer works by spraying the molten wax through the construction area through several nozzles and depositing it on the aluminum platform layer by layer. When the heated wax is sprayed on the construction plate, it will solidify. Another kind of wax with a lower melting point is deposited under the overhanging end of the design model as a support material. After printing, remove the model from the tray and place it in hot water to melt the support material. - Put the model in a container with liquid gypsum. The gypsum solidifies while the wax melts in the furnace, and finally, a mold of gypsum is obtained.

- The molten metal is poured into a mold and hardened.

- Break the mold of gypsum and a new piece of jewelry is born.

- Polish the jewelry, and then carefully clean it and polish it by hand.

The strength of using 3D printing technology in the jewelry industry

Empower flexible digital design

The traditional manual molding of the jewelry industry requires complex processes including sawing, filing, grinding and polishing, and use wax or non-precious metals such as silver and copper to obtain an original physical model. At present, for ordinary styles of rings and pendants, it takes a day for a master craftsman to make a wax model. Jewelry in complex styles will takes longer. Some may not be able to be produced in a week. The patterns of handmade jewelry are also restricted.

3D printing technology effectively solves the problems of the complex molding process and long manufacturing cycle. Jewelry designers only need to use a computer to draw 3D jewelry design, then input the STL files to a 3D wax printer, and automatic production can be performed, so as to obtain the original model, eliminate the manual modeling process.

The size of the settings of the inlaid jewelry can be freely changed in the computer 3D file, thereby eliminating the trouble of having to remodel when the setting is changed. Theoretically, using 3D technology, the same inlaid ring can be set with any size of diamonds by simply adjusting the data in the software. In this way, a jewelry computer design is equivalent to at least 10 model samples.

Automated production shortens the cycle

The designer can just import the design data to a 3D wax printer before getting off work. The next day, all the jewelry wax models will be presented on the work platform. The printer can automatically run at night and print hundreds of small wax patterns. In the 3D wax printing process, the complex molding process can be completed without manual operation, which not only improves the efficiency of jewelry model manufacturing but also shortens the process production cycle.

Exquisite and accurate digital control

Because jewelry has a certain thickness, masters need to use internal calipers to manually measure whether the thickness is the same in each place. But after all, handmade is not as precise as the computer. It is difficult for a human to achieve the same thickness, and the machine can. The printer can print as thick and uniform as the computer instructs. The 3D waxy printer can reach an accuracy of 0.016 mm.

Exclusive customization with high cost performance

The emergence of 3D wax printing technology has rewritten the current situation that only large-scale production can reduce costs. Since then, we no longer need to reduce costs and improve quality through mass production. We can obtain high-quality customized products at batch prices through small or even single piece of jewelry production, and meet the market’s demand for personalized products. The requirements also address the production of products that cannot be achieved with conventional technology.

The future of 3D printed jewelry

Although due to cost or technology maturity and popularity in the current, the scope and depth of 3D printing are not high, we can clearly see that this technology will be trendy in the near future, and bring a huge wave of innovation to the traditional jewelry industry. Below lies some perspective on this upcoming technological revolution.

- Consumers tend to but the 3D file rather than a physical

With the rapid development of 3D jewelry printing technology and continuous research and development of precious metal materials, in conjunction with 3D gem scanning, 3D jewelry digital technology, personalized personal design, and customization will be realized in the future. Individuals can print the jewelry they need at home or anywhere. Individual purchases will not be finished jewelry products by jewelry companies, but those used to print and manufacture jewelry data patterns and raw materials needed to print jewelry. Individuals can modify and design the data independently, and enter the 3D jewelry printer to print out the required jewelry. - Intelligent technology Intelligent production

Due to the digital nature of 3D printing technology, jewelry companies should establish intelligent production factories to form large-scale personalized customization, and cooperate with 3D jewelry software developers to develop and form bundled sales. Consumers can use the jewelry APP terminal installed on their mobile phones and use intelligent 3D jewelry digital modeling software to design exclusive jewelry that suits their personality requirements and send it to the jewelry smart factory. The jewelry smart factory uses 3D jewelry printing technology to make consumption Exclusive jewelry designed by the author and mailed jewelry to consumers through the Internet of Things. This is a prospect that is about to be realized, and all practitioners in the jewelry industry must be prepared to meet the changes that the revolution will bring to the industry. The result of this change must be to meet the individual needs of everyone to the greatest extent, and it will not bring about a significant increase in cost. - Personal entrepreneurship and unlimited creativity

The biggest obstacle to personal entrepreneurship in the jewelry industry is the problem of production and processing, and 3D jewelry digital technology solves this problem. First, designers do not need the assistance of professional jewelry technicians. They can solve the problem of making prototypes through 3D digital modeling technology. Second, they do not need to build their own factories. They can print and manufacture directly through 3D jewelry metal printers, or transfer them to smart factories. Smart factories make jewelry based on data. From then on, the production scale of jewelry companies will no longer be the decisive factor of the enterprise, but instead will be creative design, which provides space for the development of independent jewelry designers.