Looking for higher durability and more thermal resistance? ABS might be the material for you. Check out our review of Hatchbox ABS, a popular budget-friendly option.

What’s Special

Hatchbox is a filament brand based in the USA. It offers a large variety of filaments, ranging from everyday PLA and ABS to exotic blends.

Boasting high-quality materials, Hatchbox advertises a plus or minus 0.03-mm precision in all of its filaments (that’s right – all of them).

Hatchbox ABS is marketed as tough, durable, thermally resistant, and having the “highest dimensional accuracy”, offering a glossy finish and the ability to be used for functional production models.

Hatchbox ABS is available in a large variety of colors and in both 1.75-mm and 3-mm formats. For our review, we chose a spool of True Orange.

Verdict

Printing with this filament offered the typical ABS experience – that is to say, it was slightly troublesome. This filament is extremely sensitive to changes in settings, prone to warping, and is generally a pain to begin printing with. That said, when it does work, the models come out quite nicely and have a good finish with well-defined detail.

We would recommend this filament to someone willing to spend the time to tune their settings for optimal results, but if you’re looking for a filament you can “just use”, then this is definitely not the material or you.

The Hatchbox ABS came well packaged in a recyclable cardboard box, with a resealable bag and desiccant pouch for safe storage between uses. We tested our spool using an Original Prusa i3 MK3S in stock configuration. The color of our prints was uniform and vibrant, and the finish was very glossy and smooth.

Test #1: 3DBenchy

Our first test, as usual, was the 3DBenchy. After a number of failed attempts, we were able to get a finished Benchy. The first completed Benchy looked disastrous, with a finish only fit for horror films. With a single change to our cooling settings, we were able to get a Benchy that actually looked halfway decent.

Our original issue was bed adhesion, something that plagued us throughout our entire testing process. We tried a number of things with no success, first glue stick, then “ABS juice” (ABS in an acetone solvent). Our model kept warping from the bed and running into the extruder, breaking the model free from the print bed. To solve this, we found that we had to enclose the MK3S to avoid warping. We still had a slight bit of warping after that, but it was reduced to the point where we could get a successful print. This was the only print for which we had to use an enclosure during our testing.

Our next issue was print cooling. Using a standard ABS profile with no cooling wasn’t working, so we enabled the fan at 25% speed. This single change had a massive effect on the final surface finish, turning what was a monstrosity into an acceptable print.

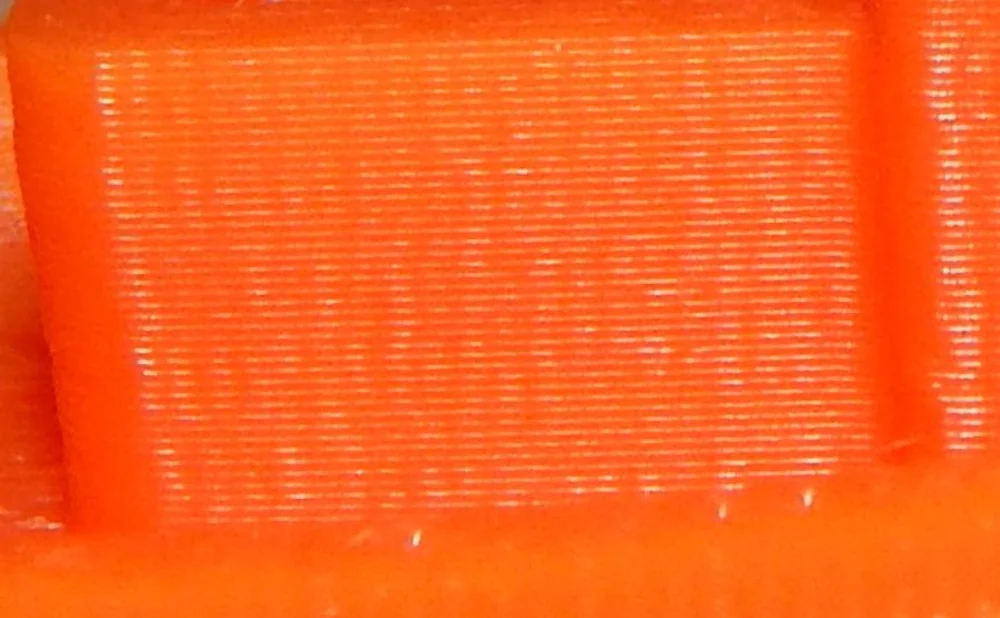

A close-up shot of the nicer Benchy reveals uniform layers with excellent adhesion.

Test #2: Excavator

Our second test was an Excavator by MakerBot.

Similarly to the Benchy, we had several failed attempts to print this due to problems with bed adhesion and warping.

Our successful print used both a solution of ABS goop and a raft for proper bed adhesion. Even so, there was some warping and the arm delaminated slightly, resulting in the rather obvious imperfection in the center.

Issues aside, the final model is very strong and durable, even where the imperfection marred the surface finish. The raft came free of the part easily after we removed it from the print bed. All of the print-in-place joints actuate very cleanly without any rough patches or hitching. The majority of the model has a very clean, even surface with a nice, glossy finish.

Test #3: Reversing Spiral Cone

Our third test print was a Reversing Spiral Cone by Joey Muirhead. Unlike the first two prints, this model was surprisingly devoid of issues. We attribute this to the simple, circular base of the print, and the additional cooling that we used after the initial disaster with the Benchy.

All of the details in this print turned out very nicely, with only a few rough patches under the overhangs. We also experienced a little bit of stringing towards the top of the model, but it is almost unnoticeable.

Final Thoughts

Overall, this filament is decent and provides good results after a bit of tuning. We found that objects with more complex bases are difficult to print, as this material is prone to warping and delaminating from the print bed. However, implementing additional adhesives such as ABS juice and a raft seem to clear up this issue. Also, we found that this ABS requires a small amount of cooling to print nicely.

So, if you are willing to take the time to dial in your printer, this filament is certainly capable of giving good results. That said, this is an additional hassle that many users may want to avoid.

All in all, Hatchbox ABS is a good filament for the price, but it’s certainly not for everyone.

Specs & Settings

We tested our Hatchbox ABS on an Original Prusa i3 MK3S in stock configuration with PrusaSlicer.

We used the “0.15mm Quality MK3” and “Generic ABS” profiles, with the following changes:

- Extruder Tempurature: 225 °C

- Bed Tempurature: 100 °C

- Fan Speed: 25% (Fan always on, disable until 3rd layer)

The manufacturer’s recommended settings are as follows:

- Extruder Tempurature: 210–240 °C

- Filament Diameter: 1.75 mm or 3 mm (±0.03 mm)

How We Review

For those curious about how we got to our conclusion, we review filaments using the following guidelines:

Each and every spool is brand-new and unopened.

Our first print is always a 3DBenchy. We use this to check for any inconsistencies in quality, color, and finish. After that, we print a few other models, the results of which we present to you. We slice the model using the latest version of PrusaSlicer. We do not post-process the prints in any manner; we simply remove them from the bed and cut off any support materials.

We start with the manufacturer’s recommended settings (where available). When the manufacturer offers a range of values, we go for the arithmetic mean. Therefore, if we are given a printing temperature range of 200–220 ºC, we would print at 210 ºC (unless noted otherwise).

For this review, we used an Original Prusa i3 MK3S in stock configuration. Statements regarding print quality are based on the printer’s ability and reputation to successfully print a wide variety of other filaments and models.

We would like to mention that every spool of filament can be slightly different, and filaments often vary greatly even within a small range. Simply fiddling with a single setting like retraction can have huge effects in print quality. This can make the difference between a disastrous fail and a wondrous success.

So, if you own a spool of this filament, we invite you to contribute in the comments below! Did you manage to get your prints to turn out? Did you have an interesting or strange experience? Let us know – we’d love to hear from you!

Feature image source: Emmett Grames / All3DP

Source: https://all3dp.com/2/hatchbox-abs-3d-printer-filament-review/