Material and part inspection is a vital stage in the additive manufacturing process – and yet it is not without its challenges. For applications within the aerospace, medical or automotive industries in particular, it’s crucial to ensure that a part meets perfection, with no hidden flaws. However, issues like porosity, voids and inclusions, particularly for metal parts, can easily make the difference between a successful or failed print. While there are several methods for verifying the quality of materials and parts, few are able to detect problems deep within the part itself.

X-ray CT scanning technology may well be the solution to the inspection of materials and parts for additive manufacturing. Expanse Microtechnologies is a company that helps manufacturers optimise their materials, parts and manufacturing processes for 3D printing using its proprietary Microscale X-ray CT technology. We spoke with James Hinebaugh, President and Co-Founder of Expanse Microtechnologies, to learn how its innovative technology can help companies perfect their manufacturing processes.

Could you tell us a bit about Expanse Microtechnologies?

Expanse Microtechnologies is a company that helps manufacturers answer questions about their materials and manufacturing processes. We use cutting-edge inspection tools to address critical questions within additive manufacturing and other advanced manufacturing fields.

In industry, you have fast-paced research needs which means you can’t wait for a research agreement to be set up with an academic lab. Expanse Microtechnologies bridges the space between industry and academia. Our aim is to bring the tools of academic labs to industrial clients, specifically focusing on a technology called Microscale X-ray CT.

Why did you decide to co-found the company?

We were inspired by the additive manufacturing industry. We saw that the industry had burning questions, and yet there weren’t any great tools on the market to help companies answer these questions and optimise their manufacturing processes. For us, CT is the solution – we wanted to use our CT expertise, apply it to the field of AM and offer fast but very focused solutions to help companies answer key manufacturing questions.

What is Microscale X-ray CT and how does it work?

Microscale X-ray CT allows you to conduct internal and external 3D inspections of advanced materials and parts. You can also characterise an almost endless number of geometrical features, defect properties and determine how well the part was printed or manufactured. This kind of technology has an enormous learning curve, which is why there are very few service bureaus providing any kind of service for CT, and most aren’t providing the same tools that you’d be able to find if you started a relationship with academic research lab.

We’ve developed advanced image processing methods to extract certain information from 3D images. As these images can be several gigabytes in size, our job is to present this information in a digestible way so that our clients can clearly see where their problems are.

We generate a report from the CT scan that provides this high-level information and access to more in-depth data, so you can find correlations between locations in your part and the defects, as well as the shape, size and the distribution of those defects.

Why is X-ray CT so important to the manufacturing process?

CT scanning provides a three-dimensional set of information that is attainable in no other way. Similar to a microscope, you can zoom into the micron and submicron level and answer key questions. Additionally, you can answer questions about internal inaccessible features of a part – which would otherwise be impossible to do without destroying the part.

With CT scanning, you can clearly see the cross-sections of your parts or test artefacts that you’ve manufactured. It’s like being able to cut your part in half repeatedly, with slices that are just several microns in distance from each other.

This creates a lot of three-dimensional information which is critical to understanding what’s happening inside your part. The alternative approach is to take just a physical cross-section: but here, you have to guess what it looks like above and below the physical plane or hope that this is a representative plane. With CT, you see not only that cross-section, but also thousands of other cross-sections and understand what the representative cross-section actually looks like. We can also see the correlations; for example, where there is porosity there are also often surface defects and we can relate that back to the parameters and the toolpath that we plugged into the print in the first place.

Could you explain how your software differs from similar software on the market?

Our software is custom-created. This means we have a lot of freedom to determine our starting point and the questions that need to be answered so we can address the problem from whatever angle we want.

An example: in the case of surface roughness, we’re developing a tool to take a CT scan and match any contours that the material and part have. We can then find a contour, extract that out and measure the roughness off of that contour. Right now, other software packages aren’t geared to do this, as there is not a lot of demand for surface roughness from CT – but in additive manufacturing there is. We can see that demand, react to it and create a tool to answer these questions. It takes us two to three weeks of development to do this and create a repeatable process. By then, it’s ready to go.

With a large commercial software package, you first need that market pressure and assurance that there is enough market potential to create a user-friendly analysis package that can answer these questions before anything can be developed and released. The lead time for this months, if not years, whereas for us it takes just a couple of weeks to figure out how to create a solution and implement it based on our clients’ specific needs.

What are the types of companies you’re helping?

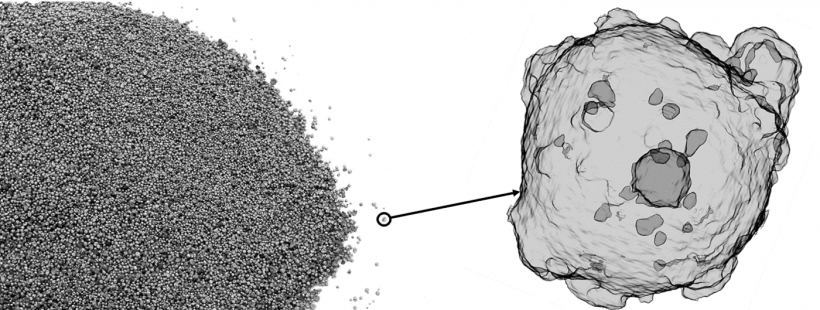

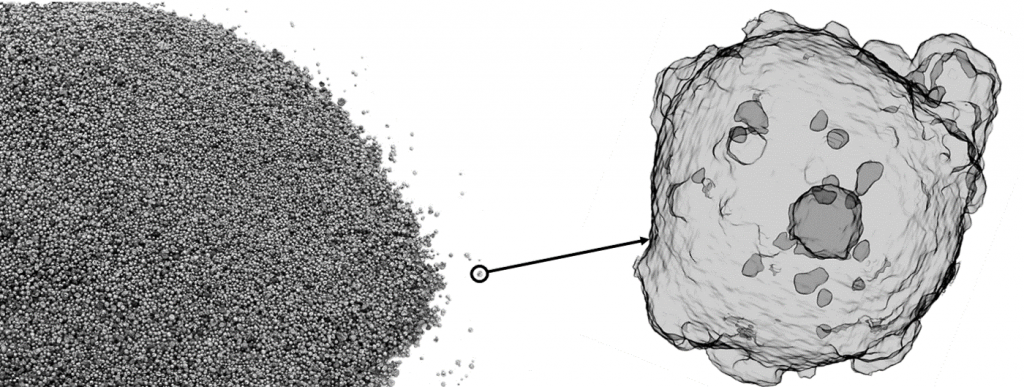

We’re addressing virtually the whole supply chain of additive manufacturing. For example, we’re working with powder manufacturers, scanning powders to identify whether there is any porosity or whether there are interesting shape distributions and size distributions critical to build quality and strength properties of the parts.

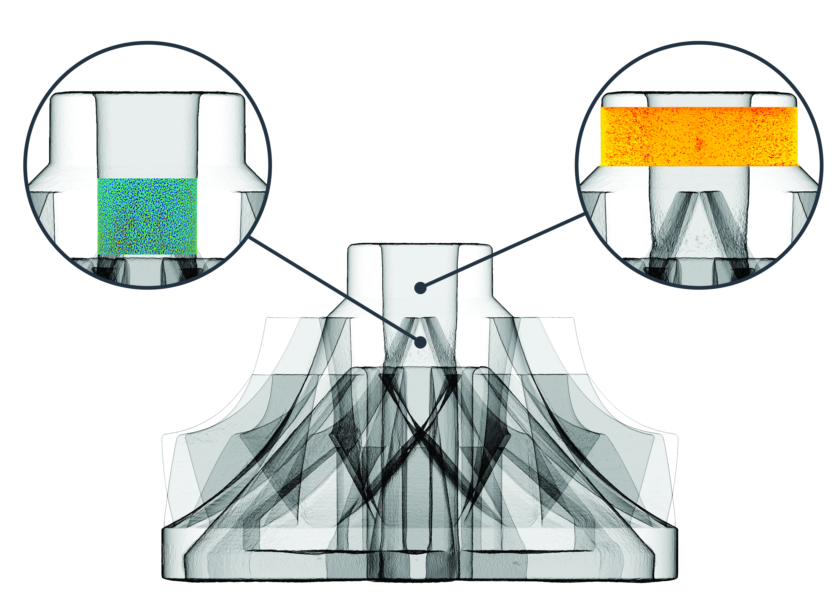

In the case of machine manufacturers, many companies want to add certain features to their current machines in terms of in-process monitoring or local control of material properties. That takes a lot of iterative testing, which is why we develop custom tools so that they can keep track of the important metrics if they need to.

We also work with service bureaus, who are often dealing with new powders, trying to commission new machines or want to have a better idea of what their print repeatability, where the porosity is coming from and other key questions.

Finally, we have clients that are trying to bring products to market that are only possible through additive manufacturing. These could be companies creating medical implants, for example – we even have one client trying to print entire rockets using additive technologies! We’re very eager to work with those companies because they are who we really want to enable in the future – we want to give them the information that gives them that control.

What are the main challenges these clients are facing?

Powders are the key point of interest across this whole supply chain of additive manufacturing. Understanding what makes a good powder that spreads and prints well is a key concern for companies. There are a lot of variables here, not only among the different powders but also with different machines. You really need an even, uniform thickness and density powder layer to be spread across powder bed printing technologies, or else you have too much or too little powder which can cause lack of fusion or overmelting respectively.

It’s important to understand 1) whether there is an ideal morphology or an ideal size or morphological distribution that can interact well with a wide variety of recoaters and printers, and 2) how we can reduce the defects in powders like inclusions and intraparticle porosity which, studies have shown, oftentimes gets trapped in a part and can’t escape the part during the print process.

Another point of interest, which is more experimental, is knowing what to do with all the in-process monitoring data that is either already available on your machine or will be available. CT will play a critical role in working that data into in-process part and build inspection. Universities and machine manufacturers have a great interest in solving this issue – but what is certain is that a lot of high-level technologies like machine learning and computer vision will play a key role. That’s definitely something I’d keep my eye on and we’re preparing and working with the right partners to be at the forefront of that research.

Could you share an example of a customer success story?

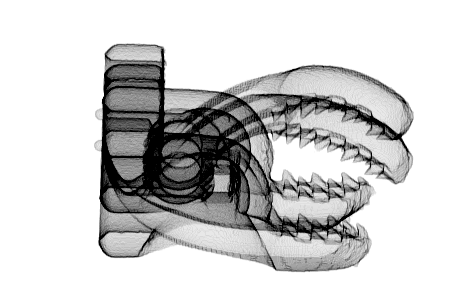

One of our customers is creating a medical device – a titanium printed spine clamp that is implanted into the body. They’ve created a very innovative solution that’s only possible through additive manufacturing.

However, the first prototypes they printed didn’t function properly. The parts were supposed to be printed with flexibility to be adjusted during the implant process – but they were printed rigid. Without knowing where to cut the part in half, they didn’t know where the print was getting gummed up by extra material or the surface on two opposing walls touching each other.

Within two weeks of them sending us the part, we were able to scan it and provide the visuals they needed to identify where this the mechanical issue was happening. This allowed them to quickly determine what they needed to change about their manufacturing process. And that was just a question of changing the build file and changing the orientation of the build very slightly to prevent the points that were creating the binding from having an unwanted material connection.

So very quickly they had a solution for their next print, which didn’t require a massive set of new analysis tool to be developed for them. All it needed was people familiar with the additive manufacturing process and the right inspection capabilities to help them out. And we very quickly got them to their next design stage.

How do you see additive manufacturing evolving?

I’m excited about it becoming increasingly easier for companies to adopt AM in the future. Right now it’s a very cumbersome technology to get up and running and to have early print quality at the level where you want it. I think there’s currently a barrier to entry that’s not just about cost but also a significant time commitment. So I’m excited that things like the smart use of CT, developed in-process monitoring and the understanding that major research labs are providing to us about the process will eliminate those barriers, reduce the price of machines and powders and reduce the time commitment required to get into using additive manufacturing.

Additionally, right now there are stringent regulations by the FAA and FDA with regards to parts being printed, whether it’s aerospace or medical. Currently, if you have a part that’s qualified and approved by the FAA, the part must be printed on the same printer using the exact same material without any changes. If anything does change, you almost always have to go back to square one and re-qualify your entire process.

We’re actively trying to help solve this problem by standardising methods for tracking machine quality, helping compare machine to machine and powder to powder print behaviour so there is a way to shortcut the requalification process. So if you need to print a part on five new machines, it’s not going to take five times the original qualification effort. There need to be shortcuts developed so that this can be a more fluid manufacturing technique in this area of industry.

Any final thoughts?

We’d love to give credit to two major partnerships for contributing to our success. One is with the University of Waterloo Multi Scale Additive Manufacturing (MSAM) lab, led by Ehsan Toyserkani and Mihaela Vlasea. They’ve been able to show us what is needed within additive manufacturing, and have allowed us to make use of their AM and CT equipment.

The second is with The Barnes Group Advisors, with whom we’re working to develop standard tools for printing and CT inspection. The group has expertise knowledge in integrating the additive manufacturing process into production, as well as the quality and inspection requirements associated with this. The Barnes Group Advisors know that CT is a critical inspection tool for understanding how to make parts and how to keep track of part quality over time.

Source: Expert Interview: James Hinebaugh of Expanse Microtechnologies – AMFG