If you enter the threshold of 3D printing, you will hear the material, photosensitive resin, always occur together with two major 3D printing technology: SLA & DLP.

Stereolithography (SLA) and digital light processing (DLP) 3D printing are the two most common processes for producing high-accuracy, isotropic, and watertight prototypes and parts in a range of advanced materials with fine features and smooth surface finish. The most often used material for SLA and DLP is photosensitive resin.

What is Photosensitive Resin?

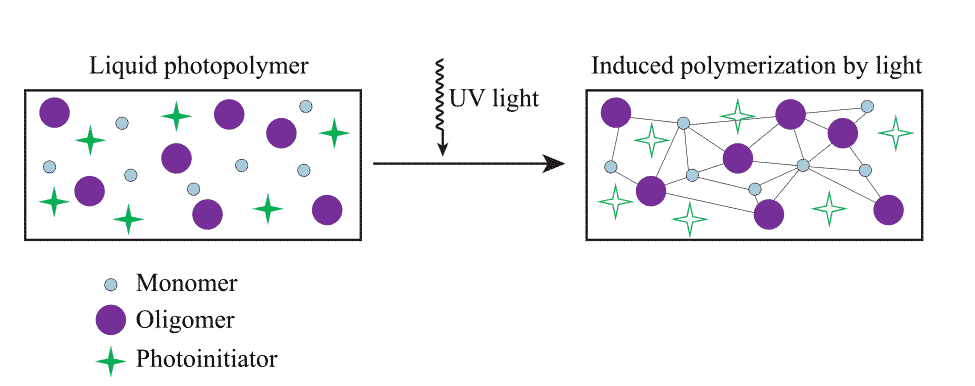

The photosensitive resin is also known as photopolymer, light-activated resin, and UV curable resin. It is a polymer that changes its properties when exposed to light, often in the ultraviolet or visible region of the electromagnetic spectrum. These changes are often manifested structurally, for example, hardening of the material occurs as a result of cross-linking when exposed to light.

Typical UV curable resins consist of oligomers, monomers (which act as diluents), photo-polymerization initiators, co-initiators (spectral sensitizers, reducing agents, etc.) and various additives such as stabilizers, antioxidants, plasticizers, and pigments.

UV curing has many advantages over conventional curing in terms of less energy consumption and equipment space, reduced waste, less emission, higher productivity (fast curing) and lower temperature setting. In addition, UV curable resins usually do not contain any organic solvents that have an adverse effect on the environment. They are applied to make prototypes, jewelry models, dental surgical guides, and functional parts.

Why do Photosensitive Resins turn yellow?

Materials in classical stereolithography are currently suffering from two drawbacks. On one hand, cross-linked photopolymers have low toughness compared to most engineering polymers (e.g., thermoplastic materials such as polypropylene or ABS). On the other hand, the long-term properties of the utilized photopolymers are not sufficient. Photopolymers tend to yellow over time and, due to the tendency to take up water in a humid atmosphere, their mechanical properties degrade over longer periods of time. Yellowing first presents as a light tone all over, then progressively darkens until it reaches a dark brownish-yellow hue. Yellowing will be accelerated with exposure to UV light.

Non-yellowing Photosensitive Resin

Polymer bases for photopolymers include acrylics, polyvinyl alcohol, polyvinyl cinnamate, polyisoprene, polyamides, epoxies, polyimides, styrene block copolymers, nitrile rubber, etc. The majority of commercial light cure resins are based on free radical curing acrylic compounds (acrylates) and listed below. They are all extensively used in different industries but only Acrylated Silicones have an outstanding non-yellowing attribute.

Acrylated Silicones

Silicones are well known for their excellent release properties as well as for their good heat, weathering, and chemical resistance. They also have good adhesion to many substrates including metals and plastics and have a very broad service temperature range of about -60°F to 500°F (-50°F – 250°F). Other important properties include good scratch and abrasion resistance, non-yellowing, excellent optical clarity, and good/excellent electrical properties. This class of UV curable resins is often used as protective coatings for optical fibers and as potting and encapsulation of sensitive electronic elements such as sensors, connectors, capacitors, inductors, switches, and relays. They also find (limited) use as UV-curable adhesives for demanding applications where outstanding flexibility, toughness and abrasion resistance is required. However, this class of adhesives has usually low bond strength which limits their usefulness.

Acrylated Urethanes

One of the most important UV curable systems is based on acrylate modified urethanes. Typical prepolymers of this class are made by reacting low molecular weight polyester or polyether diols with an excess of aliphatic or aromatic diisocyanates. The remaining diisocyanate functionalities are then capped with a diacrylate monomer which results in acrylic functionalized monomers. Reactive diluents with one or more vinyl groups are often added to reduce the viscosity of the prepolymer. The prepolymers are then cross-linked in a free radical type polymerization by exposure to UV radiation. UV-curable acrylate urethane systems have good all-around performance properties on many substrates. They usually have good or excellent film hardness, elasticity and cure speed depending on the prepolymer used. Because of their superior durability and flexibility, they are often used as resilient floor coatings and as coatings for flexible packaging. Other applications include printing inks, paper, and cardboard coatings.

Acrylated Epoxies

Epoxy acrylates are very popular UV curing systems. They undergo fast radical-induced crosslinking when exposed to UV radiation. They are extensively used in lithographic inks and varnishes, as well as in printed circuit board, wood, concrete and plastic coatings. They have good all-round properties combined with fast cure rates and exceptional adhesion performance due to the presence of polar hydroxyl and ether groups in the epoxy backbone structure. They also have outstanding corrosion resistance. Both aromatic and aliphatic epoxies are employed. The most common acrylate and methacrylate epoxy oligomers are based on diglycidyl ether of bisphenol A (DGEBA) and derivatives of it. Other important epoxy acrylates include epoxidized fatty acid oils such as soya or linseed oil and acrylates of epoxy novellas.

Acrylated Polyesters

Acrylated polyesters are produced in a wide range of reactivities and viscosities and are mainly used in printing inks, wood, and paper coatings. They are very attractive resin systems due to their relatively low cost and due to a large number of esters available which allows for a wide variation of properties. Both saturated and unsaturated esters have been reported in the literature. This class of UV curing resins has often reasonable all-around performance but only average properties when compared to the other resin systems. They are typically lower in viscosity than epoxy resins and more versatile because they are more compatible with other prepolymers and therefore can be used in a larger variety of formulations.

How can we slow down the yellowing process?

Photoinitiators

The inclusion of one or more photoinitiators is important for controlling the yellowing of the cured article upon exposure to ultraviolet light and/or sunlight. The particular photoinitiators of the present disclosure significantly reduce the yellowing of cured articles produced with the photosensitive resin compositions.

Ceramics

Ceramics offer an additional advantage since they do not suffer from long-term degradation. By using ceramic-filled photopolymers, MSL is capable of fabricating ceramic parts. If the amount of ceramic filler is higher than 42 vol%, the photopolymer can be burned off (debinding) and after further densification of the residual powder (sintering), a fully dense ceramic part can be obtained. Since the photopolymer only serves as an intermediate binder, problems with degradation and yellowing of the polymer are no issue anymore. Due to the high stiffness, good corrosion resistance, and interesting optical properties, ceramics are usable in a wide variety of applications in biomedicine and optoelectronics. Since the thermal postprocessing includes a sintering step, care has to be taken to avoid excess shrinkage and warpage of the parts.