The photos shot by unmanned drones have been trending on Instagram, which offers a new perspective of things on the earth. Journalism and aerial photography have already employed with these popular gadgets. Besides, drones also have great potential in dispatching goods and bringing impacts on urban traffic. In the future, drones will even be deployed not only in search-and-rescue missions but also in spraying crops with fertilizers or pesticides.

3D printing technology is another promising game-changer. Many companies that produce unmanned aerial vehicles (UAV) already use this technology to design and upgrade the prototypes.

As for UAV players, the biggest problem is that the drones are easy to crash into the ground due to its low battery capacity and controllability. You may take one hour to drive away from the no-fly zone, half an hour to fly the drone and uncertain time of searching and gathering the components. Replacing the components of a drone is so expensive that you would rather buy a new one.

So why not consider using the affordable and accessible 3D printing technology to make the components on your own? We can even give you more reasons.

Why is 3D Printing beneficial for drone making?

Create spare parts to save your time on searching

The time you are really flying the drone is quite limited. Usually, you would need a few minutes to get familiar with it, try to handle it, and make it flying smoothly and placidly.

When the drone is hundreds of meters high in the air, you are busy finding a proper angle to shoot a perfect photo. (The trick is just shooting a dozen of photos and select the best one on the way back home. The battery will not wait for your art creation.)

We are all easy to drop into the trap that we have become a master of flying the drones. And that is usually when the accidents happen. You’ve seen many photos of people running to catch their drones before the batteries are drained out, right? If failed, you have to search for the dispersed parts in the bushes and grass, it’s not easy work. Even if you find them, they are often not usable anymore.

Just cherish your weekend and print some spare parts. You are not ought to drive for hours to search for those unrecoverable things.

Make new components to cut down the time and cost on maintaining

If you are not an experienced UAV player, crashing and breaking parts of your drone can be normalcy. Sadly, you can’t simply use the glue to repair the broken parts. Any unsuitable repair done by players is prone to render another flight disaster.

The after-sales services of most of the consumer UAV companies are barely satisfactory. It’s seldom possible to claim for compensation, and the cost of spare parts is a little expensive. You will soon find that changing the parts of the drone is such a frequent event that buying official ones is luxury.

So why not make new components with the help of 3D printing rather than wait in line and spend a lot in the UAV companies?

Improve the flying performance and upgrade your drone

Geeks are keen to transform all the things they use, the drone is no exception. Choose a material with a low specific density can effectively extend the flight time. The composite material which can absorb vibration will help the drone to remain stable and complete in case of a hard landing or crashes. Improving the response speed and sensitivity of the drones are what those top players are considering. You can be inspired by other specialists and optimize the design structures.

Customize your drone and endow it with your individuality

To be honest, the consumers of drones are almost young people, but the UAV companies really do not offer enough choice on the appearance of the drones. The drones bought by you and your friends almost look the same. Maybe you try to paint it by yourself but worry about the uneven painting would impact the balance of your drone, or the weight of pigment would shorten the flight time.

The more possible solution is that you just send the design print and STL file to Facfox, we will choose the best material and printing techniques to realize your imagination. Facfox also offers a lot of professional post-processing methods to improve the surface.

What parts of the drone can be 3D printed?

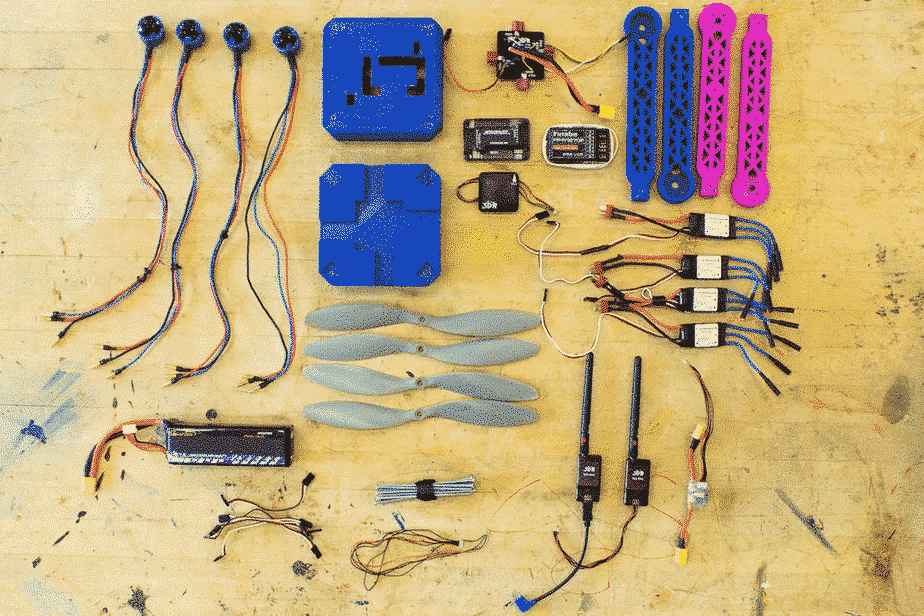

Knowing the benefits of 3D printing, you may desire to embark on printing your own drones. Except for the electrical components, all of the other parts of the drone can be 3D printed. We list them below. You can find out plenty of free STL files on Thingiverse for a whole kit or for every single part of the drone.

With proper materials and resources, you would spend even less than $100 or less to print most of the parts. We will tell you what are the best materials in drone printing in another article. It will take you approximately 12 hours to get the job done, maybe longer if you have never done it before.

Drone parts that can be 3D printed

- Camera mounts

- Landing gear

- Frame

- Antenna holder

- Propellers

- Propeller guards

- Battery and remote casing

Drone parts that cannot be 3D printed

- Brushless motor

- Battery

- Sensor