With breathtaking innovations arising in the world every day, the 3D printing field is no exception to profound development. One such fascinating component of the art is a 3D pen, and I’ve wondered long as well how it compares to a 3D printer.

Both have their own functions but essentially follow the same mechanism. This article draws a simple comparison between the two and answers the most commonly associated questions.

A 3D pen is a small-scale version of the 3D printer that’s useful in many scenarios and has become commonplace among enthusiasts and hobbyists. A 3D printer, on the other hand, comprises the larger part of 3D printing due to its immense popularity and exceptionally wide range of uses.

Continue reading for an in-depth analysis that picks up from basic components right down to more clarifying sections. By the end of this article hopefully, you won’t be left in the same situation as I, back when I started this article.

- A frame that makes up the build of the printer.

- An extruder nozzle from where the filament is extruded.

- Stepper motor(s) that facilitate the extrusion process

- A build platform where the printing takes place

In FDM, a thermoplastic material is deposited inside the 3D printer where it is melted at a specific temperature. The melted thermoplastic is then extruded out the 3D printer and onto a build platform where it cools down to gain strength, shape, and stiffness.

The process, in general, is repeated layer by layer until the desired result is achieved and you have a finely created 3D print at your disposal.

When you’re done printing, you may then go on to post-process your newly made model. This includes a series of steps where the main goal is to make your print as smooth, professional, and high-quality as possible.

What is an SLA 3D Printer?

Stereolithography Apparatus (SLA) uses an ultraviolet laser and a photosensitive liquid-based resin to make top quality prints.

An SLA 3D printer differs from an FDM 3D printer in many unique ways and is thereby deemed more appropriate for all those prioritizing smooth surface finishes and nonpareil precision.

Each SLA 3D printer comprises the following main sections:

- A tank that contains the liquid-based resin, which is actually clear plastic.

- A build platform that immersively moves up and down inside the tank according to the print procedure.

- A powerful laser beam that guides the print job layer by layer.

- A digital interface that provides total control over the SLA printer

Synonymous with SLA 3D printing is the Digital Light Processing (DLP) technique. In this technology, a projector screen is used to 3D print instead of a laser. Many consider it an upgrade over the regular SLA method.

SLA 3D printers are usually large and can host sizeable prints without sacrificing quality. The amount of detail and depth that these printers consistently provide makes them desirable over an FDM 3D printer.

Other less common forms of 3D printing include Selected Laser Sintering (SLS), Electron Beam Melting (EMB), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS).

What are 3D Printers Used For?

3D printers have several uses in so many different fields that it’s hard to describe the applications of 3D printing simply. Realistically speaking, 3D printing can complement almost any other hobby out there that uses physical objects.

You’ll hear mentions of 3D printing in the following fields:

- Medicine

- Art & Design

- Manufacturing

- Automotive

- Aerospace

- Gaming

- Food & Cuisine

- Remote Control Models

- Robotics

- Household DIY Projects

FDM works best for strength and durable 3D printed objects, while SLA can get more fine, high quality objects that looks great close-up. Although SLA provides the best quality, a well-tuned FDM 3D printer can really deliver amazing quality too.

3D printing is especially amazing for customization, namely in prosphetics where you can get exact dimensions of an individual and tailor a prosphetic leg or arm perfectly.

We hear 3D printing referred to as rapid prototyping because you can go from idea to design to object within hours, something you would find extremely hard with traditional manufacturing methods.

One user told a story of of part of a washing machine breaking, looking for that specific piece and having no luck due to non-production. He went out, designed and 3D printed the very part, and it worked perfectly.

Another example is a DSLR camera lens cover which can cost between $15-$20, but with 3D printing, the cost in plastic for each piece after fine-tuning the design was less than $0.50.

Costs are significantly lowered and customizations are significantly improved with 3D printing.

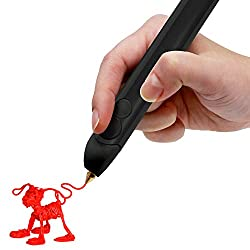

What is a 3D Pen?

A 3D pen, like a 3D printer, uses a thermoplastic filament as well that comes oozing out from the tip, rather than using ink like a normal pen. It uses filament like PLA or ABS and is designed to be safe for beginners and children.

Similar to how an FDM 3D printer has an extrusion system which pushes filament through, the 3D pen has a mechanical design that pushes melted filament through the tip of the pen, which cools and hardens quickly to create a 3D object.

The above is the description of a ‘hot’ 3D pen. We also have a ‘cold’ 3D pen which I’ll describe below.

This technology is more like an SLA 3D printer which uses a resin-based liquid instead of filament.

The cold 3D pen has a strong UV light which hardens the photosensitive resin and produces the plastic layers that are extruded to make a 3D object. You don’t require any software or extra gadgets to get a 3D pen going.

Both types of 3D pens are powered either by batteries or a cable connected to a standard wall socket or USB.

Take a brief look at a 3D pen’s functioning here in this well-made YouTube video below.

What are 3D Pens Used For?

3D pens admittedly are less common, but they definitely have their applications in many fields.

3D pens are used:

- In classrooms to showcase geometrical shapes in Mathematics, or even physical structures in biology or chemistry

- To create arts, crafts & sculptures

- In fashion & design to even create 3D printed clothing

- To complement a 3D printed design by filling in gaps or joining together broken pieces of a print

- To prototype and draw architectural models

- For keeping your kids busy and entertained at home safely!

They are really great for educational purposes as you can see in some of the bullet points above. 3D pens also have their place in the life of a hobbyist and even professionalys alike, so I wouldn’t downplay a 3D pen when compared to a 3D printer.

3D Printer vs 3D Pen

Let us now take a good look at how 3D printers and 3D pens face off against each other. The following important aspects break down things in a descriptive manner.

Quality – How Do They Look?

The simple answer here is a 3D printer is going to give quality magnitudes above a 3D pen. Even a badly-tuned FDM 3D printer is going to deliver much better quality than a 3D pen because of the levels of precision within the printing process.

The quality of a 3D pen really depends on firstly the quality of the pen, and even more so the expertise of the artist behind the 3D pen.

There are some really good 3D pens that are described as professional-grade which hold the potential to create amazing quality prints with admirable quality. If you are a beginner though, you shouldn’t expect the greatest quality objects.

But, given the size and the physical capacities of a 3D pen, the quality of a 3D printer is much superior and that’s that.

3D pens may come close to give you a significant part of the whole experience but then again, a 3D printer is a truly proficient machine that’s dedicated to excel in its functioning.

All things considered, a 3D pen can still satisfy you if your demands aren’t so high, especially in an educational or entertainment setting for kids. If you’re looking to have dimensional accuracy, functional or high quality prints, 3D printers are the way to go.

The quality they produce is still a cut above-average and can even turn out to extremely well if the appropriate amount of effort and time has been spent.

But then again, 3D printers have a range of diverse technologies they function on, such as FDM & SLA as mentioned earlier. This basically increases the dynamism of 3D printers and allows for manifold potentiality.

This means that there’s a ton that you could achieve with a 3D printer, and your end product’s quality will be miles ahead of anything that a 3D pen could produce.

Printers have basically an abundance of flexibility to their name. Is FDM not hitting quite home for you? No problem, switch up your gameplan with an SLA printer that uses a resin-based filament for the utmost supreme quality of prints.

As you can see, a 3D pen in this matchup doesn’t really stand a fighting chance.

Strength – Am I Getting Strong Parts?

On top of the quality aspect of this comparison, 3D printers also take the win in the aspect of strength.

When you factor in the precision of 3D printers along with level of infill, shells, and compatibility of materials you can use with a 3D printer, they easily overpower the strength of an object made with a 3D pen.

Parts that are 3D printed with a pen might not be very strong, but they can hold up fairly well in your average environment. What you can do is try printing thicker by going over the same area again and again and form a better, stronger layer.

This makes your part able enough to withstand active play and slightly capable enough to withstand some weight. Other than that, don’t expect much from a 3D pen, especially not when compared against a 3D printer.

You see, a 3D printer makes use of all its powerful components, such as the nozzle and the extruder motor to co-create a strong, durable print. The machinery allows it all the enhancements, so the 3D printer itself could produce a better output.

Moreover, decent quality 3D printers have the capability to work with very demanding thermoplastic filaments. This category includes Nylon- a filament powerhouse that packs the best available durability and strength you can ever get in your 3D parts.

Check out my article on What is the Strongest 3D Printing Filament That You Can Buy? It goes on to list some of the strongest filament which can really stand up to mechanical forces.

A notion like this is out of the question with 3D pens, with most of them being able to support ABS and PLA at best. As you can see, there isn’t a great extent of alternatives available for you in this regard so you’ll have to settle for the basic filaments.

On the contrary, you can up your game even more with 3D printers and use exotic filaments like wood-fill, and even the glow in the dark thermoplastic material.

There is a Carbon-fibre filament available as well which has its own touch of awesomeness.

To conclude it in simpler terms, 3D pens can’t offer you much in terms of durable and strong parts. If you’re looking for something like that, 3D printers are undoubtedly your go-to choice in this factor.

Ease of Use – Beginner Friendly

The simple answer here is, once you get the hang of both a 3D printer and a 3D pen, 3D printers are a lot easier to operate because it really just takes a few options selected to get it going.

A 3D pen looks simple, but if you are looking to do some kind of complex object, it can be very tough to learn first off, then the actual extrusion process and making it connect properly can be fairly tough.

3D printers back in the day were quite hard to get working perfectly, but in modern times, you can get some really amazing prints right out of the box. Yes, you may have to do some troubleshooting from time to time, but there are so many tutorials to guide you through.

If a beginner asked me which one to go for, I’d have to advise them to go with a 3D printer. If they just want a quick, cool activity to pass some time, then you should go with the 3D pens.

With a 3D printer, you do have to know some of the basic things such as downloading 3D printer files, also known as .STL files, and you should know the process of ‘slicing’ which is preparing your file in a way that your printer can understand.

Once you get the process down, you can locate, download & slice a file, then get it printing on your machine within just 2 or 3 minutes. You also have many guides on how to do this from start to finish.

Some 3D printers do take a bit of assembly, though instructions are fairly basic to follow. You can definitely get fully-assembled systems that make operation a lot easier, as well as Wi-Fi controlled printing.

Price – Which is the Best Value for Money?

3D pens are going to be a lot cheaper than 3D printers of course, but when talking about the overall value for money, this gets a little more interesting.

First lets figure out a good price that you can expect to pay for some entry-level machine or 3D pen.

The Creality Ender 3 is a staple 3D printer that is well-known as an entry-level printer and it costs around $200. A decent 3D pen can set you back anywhere from $30 up to $180 for the upper range.

If you don’t want to spend a significant amount on 3D printing, then the 3D pen might be for you. People that really want to get involved in this rapidly-expanding field should definitely opt-in for a good quality 3D printer.

Considering the cost, if you’re trying to keep it simple with 3D printing, an $80 3D pen might just be enough for your needs. Consequently, you may not need a costly 3D printer at all.

But given your requirements, a 3D printer holds the potential to go above and beyond when it comes to its functionality. There’s a lot you can do it with it, and even if it’s an inexpensive 3D printer, it’s still going to be leaps and bounds ahead of a 3D pen.

Many people who have started out with a 3D printer can confirm that this was a worthy investment. However, a plethora of 3D printers are very costly too. The Ultimaker 3 is a fully assembled 3D printer and costs well above $3,000.

While a 3D pen isn’t even close to those figures, it does come off pretty cheap.

So, when it comes to the value that a 3D printer provides, it definitely ticks all boxes. Ultimately, however, it all boils down to the fact whether you really need a 3D printer or a 3D pen.

The essentials of both have been stated down so we hope that you’ve arrived at a solid conclusion by now.

Durability – How Long Does a 3D Printer Last vs a 3D Pen

A good quality 3D pen can last up to 15 years and more. This comes from 3Doodler- a pioneer in developing 3D pens and maintaining a quality standard for that matter.

If you’re not going to run over your 3D pen anytime soon, I guess it’s fair to say that your handheld gadget can stick around for a long while.

Contrastingly, 3D printers are known to run exceedingly well for 5 to 10 years. This is because they consist of many internal moving parts and other components that are known as consumables. These are the ones that need usual replacement over time.

In conclusion, a 3D pen will most probably last a lot longer than a 3D printer, but that’s really understandable given the intricacy and required maintenance of the latter. 3D printers are also more prone to damage in many cases, may it be an accident on your end or something breaking apart in the printer itself.

Nonetheless, if you trust that you can keep your machine in great condition with the passage of time, you can be carefree that its going to break down anytime soon.

Instead, all your hard-earned spent money is going to pay off really well, considering what you can do with a fully functional 3D printer.

3 Best 3D Pens You Can Buy

Here are the top 3D pens you can buy right now.

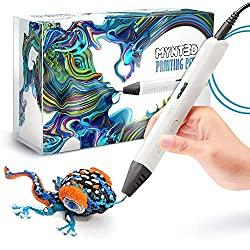

MYNT3D 3D Pen

The MYNYT3D is a 3D pen that’s undeniably a top pick for many tinkerers and enthusiasts. It’s feature-rich and a very solid option to consider when making such a purchase.

Temperature can be optimized according to the situation at hand, going up to 240°C effortlessly. Moreover, not only this 3D pen openly supports PLA and ABS, but get ready to experiment with some wood-fill elements with the MYNYT3D as well.

It has a graceful and discerning design that consists of a sizeable display screen. Besides, it’s not workable with a USB cable but instead, a power bank acts as the main energy source. In summary, around $60 for this pen is well worth the cost.

The large OLED display works great in letting you monitor the temperature of materials. It comes with a 1-year limited warranty and 3 colors of ABS filament.

Get yourself the MYNT3D Professional 3D Pen from Amazon for a great price.

3Doodler Create+

The 3Doodler Create+ is the way to go if you really want to spend a few extra on a 3D pen and truly get the best out of it.

The Create+ offers high-quality performance with consistent and precise extrusion. It features a two-speed system- slow for details and depth, while fast for speedy doodling.

Moreover, this 3D pen boasts a Dual Drive motor system, allowing you to print flexible filaments as well without any unnecessary trouble. It’s comfortable to hold and very easy to use which are quite possibly the hallmarks of 3Doodler.

Can You Use 3D Printer Filament in a 3D Pen?

Simply put, yes. Many 3D pens use the standard 1.75 mm filament diameter, which is what people are using with most 3D printers. The spool of ABS filament you’ve just bought for your printer will also work just fine if you’re thinking of getting a 3D pen as well.

However, there are a few 3D pens out there that use a filament that works at low temperatures. Similarly, the original 3Doodler Pen uses 3 mm filament diameter, meaning that the stock 1.75 mm diameter filament just won’t cut it in this case.