The California-based company 3D Hybrid Solutions is offering three metal 3D printing tools for CNC machines, including Wire-Arc Additive Manufacturing (WAAM), Laser Metal Deposition (LMD), and Cold Spray toolheads.

Ever since 3D printing emerged onto the manufacturing scene, many have debated whether or not the technology could eventually displace CNC milling as the king of the production floor. As time has transpired, it’s become clear that these dueling manufacturing methods are at their best when used together. In fact, there are a number of hybrid machines that utilize both subtractive and additive manufacturing technologies.

The Los Angeles-based manufacturing company 3D Hybrid Solutions has recently unveiled three new metal 3D printing tools for CNC machines.

After experimenting with polymetallic alloy additive manufacturing for aerospace and research applications, the company decided to develop 3D printing tools based on electrical, optical, and kinetic energy. The trio of toolheads, which includes Wire-Arc Additive Manufacturing, Laser Metal Deposition, and Cold Spray, are compatible with almost any CNC machine.

3D Hybrid Solutions has designed these complementary tools to lower the barrier of entry into metal additive manufacturing. The three different methods aim to optimize the functionality of current machines with increased speed and multi-material capabilities. The price of these metal 3D printing toolheads start at $50,000.

3D Hybrid Solutions Adds Three Toolheads for CNC Machines

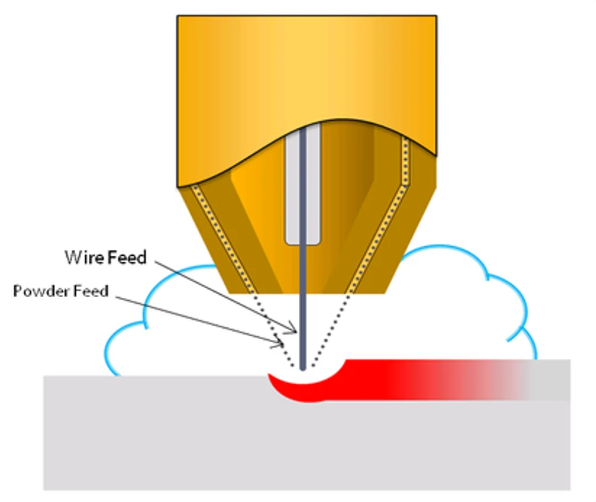

Each of these metal additive manufacturing tools offer a unique approach to hybrid manufacturing. Wire-Arc Additive Manufacturing uses a complex electrical discharge technology that is compatible with a wide variety of feed-stock alloys. This tool uses a patent pending co-deposition system that prints with both wire feed and metal powder.

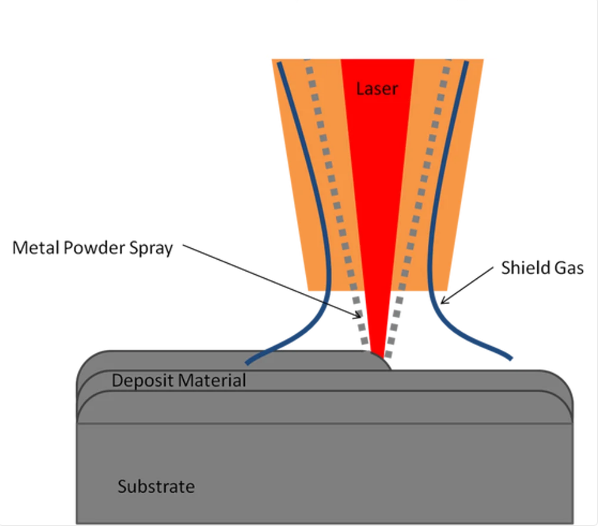

The Laser Metal Deposition tool is equipped with a laser beam energy source and a powder-gas spray nozzle. The laser is used to melt the substrate, while the powder converges into the beam and melt pool. The deposit material is then metallurgically bonded and layered to form metal 3D printed objects.

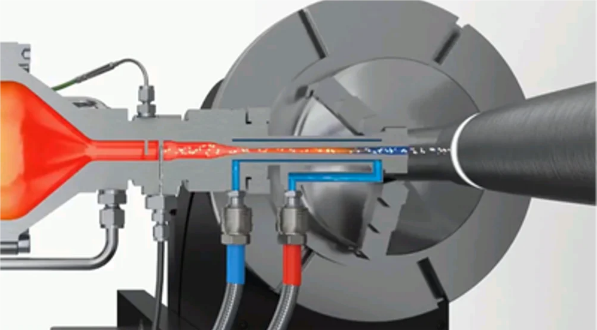

Lastly, the Cold Spray tool is fast-paced technique ideal for large scale metal 3D printing. As 3D Hybrid Solutions explains on its website, this technique “uses solid metal powders that are accelerated in a gas to supersonic speeds around 1600-3500 feet/second”. After incurring impact, these substrate particles deform and combine with the substrate as the toolhead moves above the surface.

3D Hybrid Solutions is aiming to amalgamate metal 3D printing into CNC machines. By doing so, the company is expanding manufacturing beyond a single technology. In a market where both versatility and affordability are major keys to success, 3D Hybrid Solutions is giving customers more opportunities to innovate with both additive and subtractive manufacturing at the same time.

Source: https://all3dp.com/3d-hybrid-solutions-adds-metal-3d-printing-capabilities-to-cnc-machines/