There’s plenty to learn about food safety and 3D printing. Learn if PLA is food-safe and other essential facts about food-safe 3D printing.

3D printing offers unique customization possibilities that seemed impossible until recently. Both FDM and SLA printing technologies are proliferating with hobbyists and entrepreneurs opening 3D printing to many new industries.

3D printing is gaining adoption across industries as varied and essential as medicine, dentistry, aviation manufacturing, residential construction, prototyping, and jewelry. For hobbyists, this translates to enormous fun and exciting opportunities to print a variety of unique gadgets, including kitchen tools.

But are 3D printed products food safe? If you plan to print and sell anything that will come in direct or repeated contact with food, precautions against bacteria and toxic materials are necessary.

Food safe 3D printing is possible and becoming increasingly common, but your printer won’t be food-safe out of the box, regardless of brand or price point. You’ll want to be on the lookout for materials and printer upgrades that have already been certified food safe, and be cautious about all other options.

Always beware of what you’re putting in your mouth! Read on to inform yourself on the key facts about food-safe printing.

THE PROBLEM

Food-safe 3D printing encounters two major hazards: bacteria and toxic materials. Both of these problems need to be addressed before printing anything that will come in contact with food.

Along with addressing them, you’ll need to understand the different terms used by the industry and government regulators. We’ve prepared a short guide for you to reference below.

Not All Terms Are Equal

Before we go too deep, it’s important to understand the different terms that can be thrown around when it comes to printing anything you plan to use with food. You’ll see these terms in our article and anywhere else you research food-related 3D printing.

- Food grade means something is safe for human consumption or direct contact with food. Think of it as the gold standard where no harm will come from ingesting. While some labs are working on 3D printing food, it’s not what most aim for today and isn’t the focus of this article.

- Food contact surface refers to a surface that will come in contact with food. To earn this label, something must be made from food-safe materials and designed to maintain integrity in the environment of their intended use – that includes whatever you plan to clean the print with. An example of this is cutting boards needing to maintain integrity against the knives slicing against them repeatedly, not just the food they’re touching.

- Food safe is the key term in this article and the industry in general. Your prints are food safe if they don’t create a safety hazard by being used with food. With 3D prints, you’ll need to be on the lookout for bacteria and toxins above all else to attain food-safe quality.

Food Safe Doesn’t Mean Certified

If you’re looking to sell your food-related prints online, they’ll need to be certified food safe to avoid opening you up to legal liability if someone gets sick. If no one else’s food will have contact and your own kitchen is as far as the prints will make it, you don’t need to worry about this distinction.

For those who want to sell prints that will come in contact with food, you’re probably 3D printing as a side hustle and acting as your own compliance department. A small business like yours won’t go through the EU’s or FDA’s rigorous testing process that large companies endure for certification – and you don’t need to!

But if someone gets sick from your print and the government comes calling, you’ll need to retroactively prove you could have passed the certification process. That means having a Food Safe Plan.

Among the key points you’ll need to include is a hazard analysis, meaning identifying how your print could be chemically, biologically, or physically hazardous. Once you identify these hazards, you’ll need to have written preventative controls to mitigate the risk. These can be flexible and must be tailored to your specific product and workspace. Examples include process controls, allergen controls, and sanitation controls.

Oversight

Your Food Safe Plan doesn’t end with having controls in place to address hazards. You’re also required to oversee and manage these controls by monitoring that your procedures are being followed, correcting any mistakes in a timely manner, and installing corrective processes so they don’t occur again, then verifying that your new controls are working in preventing hazards through continued monitoring.

Most importantly, don’t forget to document everything you’re doing in writing at the time when you’re doing it! Organizations like the FDA demand proof.

The last step you’ll need is a recall plan. The FDA is only knocking on your door if someone got sick. They – and your conscience – need to make sure no one else gets sick. That means recalling your already sold prints to ensure they can’t cause harm.

Keep in mind, even if you don’t view yourself as a small business, government regulators like the FDA will claim jurisdiction over anything you sell. To help you abide by their rules, the FDA offers a guide for “small entities.”

There’s Official Criteria

So what actually makes a product food safe? The FDA‘s criteria includes:

- No migration of deleterious substances

- Does not impart colors, odors, or tastes

- Safe under normal use conditions

- Durable, corrosion-resistant, and nonabsorbent

- Sufficient in weight to withstand repeated washing

- Finished to have a smooth, easily cleanable surface without breaks and sharp internal angles

- Resistant to pitting, chipping, crazing, scratching, scoring, distortion, and decomposition

- Accessible to inspection

You’ll need a plan to address these bullets to achieve food-safe 3D prints, the biggest concerns being: durable against repeated washing, a smooth finished surface that’s resistant to scratching or chipping, and no leaking from the filament, whether taste, color, or unnoticeable toxins. The FDA offers a downloadable plan builder to help.

These are the FDA’s guidelines for all products coming in contact with food. Specifically for 3D printed products, the EU and FDA each have similar regulations and offer certification for larger companies. Smaller start-ups can refer to the “small entities” rules linked above and use their best judgment in adhering to these guidelines. Nothing in these 3D printing regulations differs from the general criteria, but the regulations in your area are worth double-checking before selling prints to customers.

The food-safe criteria is particularly important for any products you’re buying specifically for food-safe printing, like your filament or printer upgrades. Look for products with official government-certified labels shown below.

Claims & Compliance Deserve Consideration

When you’re buying anything for food-safe printing, it’s important to check for the labels shown above. Companies are able to add these to their product packaging and advertising once they pass the corresponding regulatory agency’s certification process.

If you’re thinking about buying an upgrade or material for a food-related 3D print and don’t see the above labels, be careful and use your judgment. I’m sure you’ve heard this before, but don’t believe everything you read on the internet. Companies aren’t always honest and can use vague, unregulated terms like “compliant” without having done anything to ensure that what you’re buying is legitimately food safe.

On the other hand, “compliant” companies may have adhered to every rule and recommendation we listed and linked to above, but haven’t undergone the official certification process to earn one of these labels.

A good way to double-check: Food-safe materials tend to be more expensive due to the necessary extra steps in manufacturing them. Your and your potential customers’ health is worth the added cost. If you’re finding food-safe compliant products like filaments for the same price as their regular version, it’s time to be suspicious and look for a regulatory label.

For example, you’ll notice the product images on Filaments.ca often include the above symbol. This is proof that their products have earned the higher price.

Bacteria, uh, Finds a Way

We mentioned that bacteria and toxic materials are the biggest threats to being food safe.

A print from your out-of-the-box printer will never be food safe because germs can get lodged in even the smallest cracks or spaces – spaces that are abundant between layers in FDM printing. This creates a home for bacteria to flourish.

Any print you plan to use more than once with food will collect bacteria – it’s a matter of when not if – regardless of how well you clean it (which we’ll get to later). To avoid bacteria, you need to do more than thoroughly clean; you need to be addressing bacteria concerns while planning, preparing your printer, and in post-processing. Read our best tips in the sections below.

Guidelines Change Based on the Food

One of the final questions you need to consider before preparing to print, is what are you printing? More specifically, which food will the print come in contact with and for how long?

Think about it, the odds of the print imparting taste or color are higher when it’s storing raw meat for a long time and smaller when you print a bowl for cookie cutters or shelled nuts. The prints with limited food contact require fewer precautions.

Are you printing a mug? That requires filament that can withstand hot coffee or tea and that won’t migrate any substances to the beverage or the drinker’s lips from repeated sips. Probably not PLA, which some makers report warping on a warm summer’s day. We’ll go deeper into filament choices next.

You also need to review what you’ll be using to clean the print. The raw meat container needs to be cleaned thoroughly while your personal nut bowl can get away with a warm water rinse. There’s no fooling around when salmonella’s a risk.

Filament May Contain Toxic Materials

We addressed bacteria being one of the two major health risks with 3D printing. The other is toxins and toxic materials. These risks are most likely to enter the print from the filament being used.

Toxins are a serious health risk and the reason many in the 3D printing community have insisted prints are never fully food safe in the past. Looking at you, r/3Dprinting.

In addition to toxins from the materials filaments are constructed out of, you need to be careful with color choices. It’s easy to forget about safety when viewing colors as a fun or stylistic choice, but filaments aren’t naturally available in a rainbow variety. Filament producers use dyes to add those colors and each dye brings its own set of safety concerns.

For example, Prusament is proud to offer a variety of non-toxic inorganic filaments but they’re unable to craft a green PLA or PETG without dyes that potentially include toxins. Filaments.ca avoids this by only offering PETG in natural colors, limiting variety in the name of safety. This can be an adjustment for some makers, but limiting the use of colors is safest.

With any filament you end up picking, it’s best to check the material safety data sheet (MSDS) to determine the chemical properties before printing. The MSDS will include hazards from every material the filament’s manufactured out of, including coloring dyes. The manufacturer should always include the MSDS within the product’s packaging so give it a read before cutting into your filament to ensure it’s what you’re looking for.

THE FILAMENT

We’ve covered the hazards above, now it’s time to pick the filament that poses the fewest risks to your food-related print. Along with toxic materials and bacteria, this is when to consider things like durability and heat resistance.

There Are Various Filament Options

This section might be the most important when it comes to food-safe 3D printing. Which filament will you be using?

We already covered the risk of toxic materials in filaments, which should immediately rule ABS out of food-safe printing. ABS is one of the most toxic filaments on the market and you’ll be hard-pressed to find any company even pretending to offer food-safe ABS.

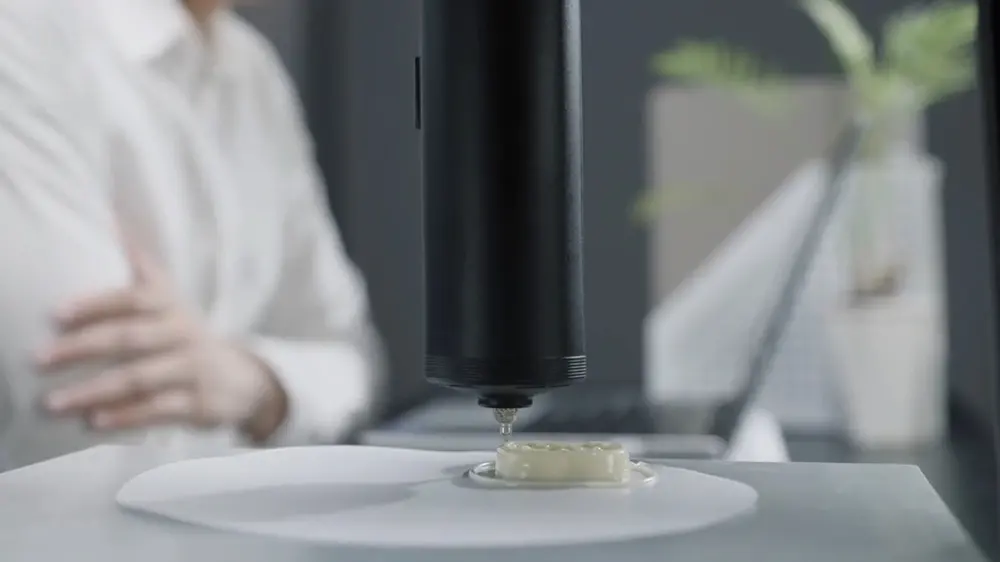

Similarly, liquid resins are extremely toxic. 3D printing resins may come out of the printing process with smooth surfaces that are great to reduce bacteria risks, but the filament itself poses too great a risk. You won’t find any food-safe resins, and resin printers shouldn’t be used for food contact 3D printing.

PLA

That brings us to the most commonly used filament, PLA. It’s a bioplastic and far less toxic than ABS or 3D printing resins, but it also brings its own questions surrounding its durability.

We already mentioned its struggles with heat, and properly cleaning PLA prints without warping or scratching them is sure to be a challenge. You’ll want to look elsewhere for anything harder than cookie cutters or forks.

If cookie cutters are all you’re looking to print, we’ve reviewed the best food-safe PLAs.

PETG

And along with PLA, another food-safe option is PETG. It’s both stronger and more heat resistant than PLA, while maintaining the same ease of printing makers expect from PLA and avoiding the toxic risk of materials like ABS. That’s what’s led brands to move past food-safe PLA and extend their food-safe product lines to spools of PETG.

No filament is perfect though, and PETG is particularly vulnerable to outdoor use due to its sensitivity to UV rays and its tendency to absorb moisture.

Regardless of the type of filament you choose, it’s always wise to save yourself additional worry and choose a filament that’s been deemed food safe. (Remember the labels we introduced above?) Filaments.ca is a market leader in the food-safe filament category, with both PLA and PETG offerings, and is well-known for becoming the first FDA-approved filament.

Bioplastic Doesn’t Mean Safe

Polylactic acid, better known as PLA in 3D printing circles, is bioplastic produced from natural materials like corn. It’s long been used as biodegradable food packaging by companies as large as Wal-Mart. Due to this, some have been quick to adopt it for food-safe printing.

But there’s a major difference in how it’s being used here. Biodegradable packaging is single-use, not a kitchen item you’re 3D printing for repeated use and potential direct contact with people’s mouths.

We mentioned the questions about PLA’s durability above, but how does that specifically impact its safety? You can check out our deep dive into food-safe PLA printing for more info, but long story short: we don’t recommend printing anything that will come in contact with food for longer than it takes to cut a cookie.

Overall, we make this recommendation for several of the reasons we’ve mentioned above – like bacteria spreading between layers of a print, the dyes used in coloring which aren’t bioplastic chemicals, and PLA’s vulnerability to heat.

Just because it’s made out of food, it doesn’t mean that PLA comes out of the FDM printing process food-safe.

PLANNING & PREPARING

Now that the hazards have been determined and the filament is picked, it’s time to turn our attention to the 3D printer. Like we said in the introduction, no 3D printer is food safe right out of the box.

Ultra-fine particles (UFPs) are always going to be a risk with 3D printing plastic filaments, so you’ll want everything else to be as sanitary as possible to mitigate health risks.

Here’s what to consider when you sit down to start your print.

Printers Should Be Clean

Now that you have everything together for your print, you need to make sure the build plate and nozzles are as clean and sanitary as possible. It might seem obvious, but for food-safe 3D printing, you need to do more cleaning than just brushing off the build plate with the back of your hand.

Consider looking into cleaning filament to keep the areas you can’t reach sanitary. For the best tips, check out our articles on cleaning printer beds and nozzles. Whichever process you end up choosing, you’ll need to clean the printer that way between every print to avoid spreading bacteria before your print even reaches the kitchen.

Also be sure to include your cleaning methods in your Food Safe Plan, since it’s surely something the FDA will want to see if they ever come calling.

Nozzles Shouldn’t Be Brass

Before printing, you want to check and likely replace the nozzle on your 3D printer. That’s because the standard nozzles on most 3D printings are made out of brass, and brass contains an average of 3.5% lead.

That’s a major risk of food-safe printing: As the nozzle wears down and degrades, it’s possible for the lead to leak out of the brass and contaminate the print. There’s no such thing as safety when lead poisoning is a serious possibility.

Play it safe and upgrade to a new nozzle for your food-related prints. There aren’t currently any nozzles on the market that have received a food-safe label from government regulators, but switching from brass to a stainless steel nozzle at least eliminates the risk of lead contamination.

Extruder Tubing May Be Toxic

There are widespread concerns about PTFE tubing emitting high levels of toxicity at high temperatures. This is due to the Teflon used in the manufacturing of the material.

Overall, these concerns are likely overblown as the high temperatures would need to extend the length of the tube and temperature ranges for PLA or PETG are well below any risk zones.

If you’re worried, you can look into upgrading away from PTFE tubing, but like with the nozzles, there aren’t any on the market with a certified food-safe label. One uncommon solution some have switched to is using all-metal extruders crafted from stainless steel pipe. Another upgrade to consider is a new hot end, like the E3D V6, that keeps the PTFE far from the heat block.

POST-PROCESSING

Your work isn’t done when the 3D printer’s turned off, but congratulations on making it this far and adhering to food-safe standards!

Now you need to keep those prints clean and free from bacteria.

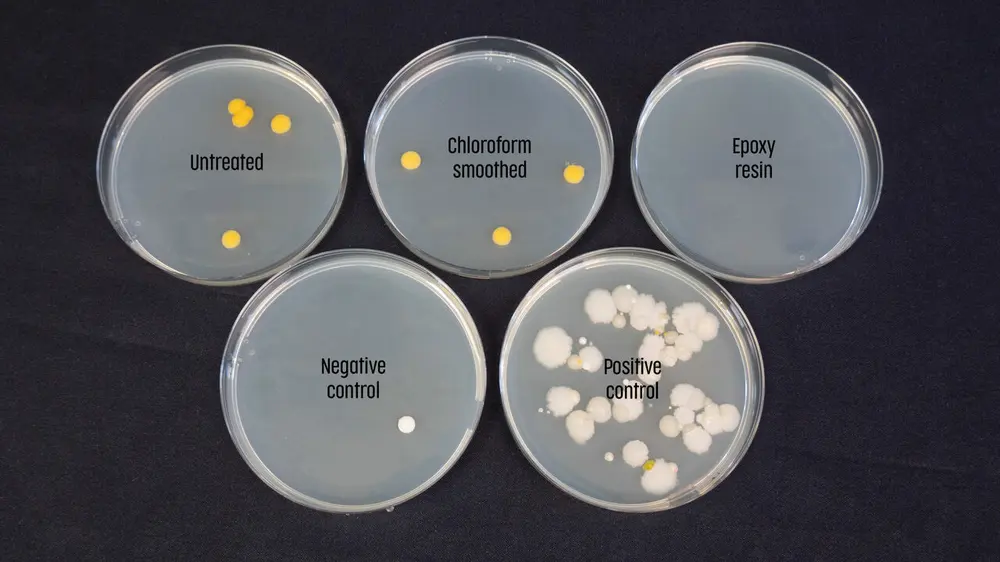

Print Surfaces Should Be Smoothed

This is the crucial step to preventing bacteria from growing between the layers: You need to smooth the surface to eliminate any cracks or spaces that could become home to germs. Smoothing surfaces is generally recommended with FDM printing for aesthetic purposes, but as we explained with the risk of bacteria, it’s essential for food-safe printing.

There are several options to tackle this task, the most common being sanding the print down or chemically smoothing the surface. Check out some of our other articles for the best options with PLA or PETG smoothing, such as polishing or heat treatment.

Sealants Ensure Closed Surfaces

Once your print’s smoothed down, sealing the top layers of your print is essential for keeping bacteria out (and keeping any potential toxins in).

Epoxy resin is the most common recommendation, with many brands and products available for the art market. Since artists have been using epoxy resins for years, there are multiple FDA-approved products and brands available that are durable and cleanable.

It’s important to remember though, just like with 3D printing resins, epoxy resin is toxic in liquid form. We recommend using gloves and a mask while using any finishing resins and following the manufacturer’s instructions to make sure it cures and hardens fully. An incorrect ratio of liquid resin or hardener can undo the hard work you’ve done to be food safe. Partially cured resin can also remain toxic, once again proving “close only counts in horseshoes”. Once it’s cured, review the manufacturer’s instructions for cleaning.

Like we’ve said, check for government certification on any food-safe claims, especially for the sealant that will cover the top layer of your filament and that will be in direct repeated contact with food. This is another time when checking the MSDS will be helpful.

Hot Water Washing Can Reduce Safety

Will your 3D print hold up to the heat and water pressure of dishwashers? Probably not, and the cracks created could multiply the risk of bacteria and add the possibility of choking hazards breaking off, not to mention toxins leaking out.

But as we covered earlier in this article, the FDA says 3D prints must “withstand repeated washing”. So what’s the best strategy for you and potential customers to keep 3D prints food safe?

Your best bet is using lukewarm – not hot! – water with non-abrasive anti-bacterial soap to scrub your prints. This should kill any bacteria while keeping the food coming in contact with the surface safe from any toxins.