For centuries, traditional arts have thrived on the mastery of natural materials – bamboo, wool, wood, clay, textiles, and more. Each carries deep cultural significance and techniques refined across generations. In recent years, however, a fascinating dialogue has emerged: how can 3D printing support, revive, and expand the possibilities of these time-honored crafts?

Rather than replacing artisanship, additive manufacturing is increasingly seen as a complementary tool, offering precision, customization, and structural possibilities that blend beautifully with handmade processes. Let’s look at some inspiring examples across different materials and disciplines.

Bamboo & Wood

Custom Joints for Bamboo Structures

Bamboo has long been prized for its strength and beauty, but its natural irregularity makes joinery challenging. By scanning bamboo culms and 3D printing bespoke connectors, architects and designers have assembled modular pavilions and furniture without nails or rope – enabling flexible yet traditional designs.

Wood Waste into New Craft

Projects like the WoodenWood initiative transform sawdust into 3D-printable composites, closing the loop of woodworking waste and giving rise to zero-waste stools and chairs. This marries the values of carpentry with digital fabrication.

Wool, Textiles & Fashion

Printed Embellishments on Fabric

Collectives like threeASFOUR have explored printing directly onto fabrics, integrating nature-inspired structures with textiles.

Hybrid Garments

High fashion designers, such as Iris van Herpen and Noa Raviv, have combined hand-stitched textiles with 3D-printed ornaments. These couture garments maintain softness and wearability while introducing complex geometries impossible to craft by hand.

Wool & Felting Innovation

While traditional felting relies on slow, manual needlework or resist molds, designers have begun exploring new ways to accelerate and refine the process with digital tools. For example, Nadine Blencowe adapted a jigsaw by attaching a 3D-printed part that holds multiple felting needles, turning the power tool into a rapid-fire felting machine. This invention enables artisans to sculpt dense wool rugs and textiles with far greater speed and precision, while still preserving the organic tactility of the material. It represents how 3D printing can act not as the final object, but as a key enabler of new craft techniques.

Ceramics & Clay

Digital Pottery

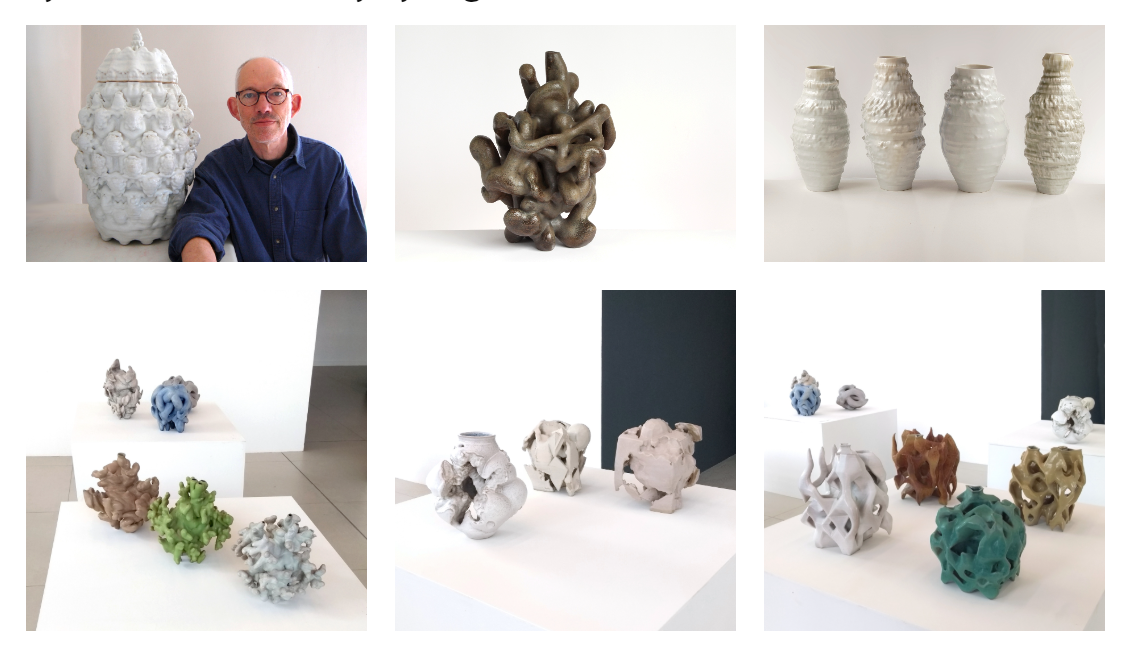

Artists like Jonathan Keep and Taekyeom Lee employ clay 3D printing to generate novel ceramic forms, which are then glazed and fired using traditional methods. This creates objects that feel both futuristic and rooted in heritage.

Cultural Heritage Restoration

Museums use photogrammetry and 3D-printed reconstructions to repair broken pottery. Instead of discarding damaged artifacts, digital fabrication discreetly restores them while honoring the craft.

Bio-Based & Nature-Inspired Design

Silk Pavilion by Neri Oxman

At MIT Media Lab, Oxman combined digital fabrication with silkworm weaving, creating an architectural installation that exemplifies harmony between technology and natural systems.

Bamboo & Biofiber Composites

Researchers are blending bamboo fibers with biopolymers for 3D printing, creating sustainable materials for furniture and even construction.

Empowering Traditional Craftspeople

Projects like CRAFT3D (EU-funded) and collaborations with rural artisans in New Mexico and California show how 3D printing is not limited to artists in high-tech studios. Through education and digital training, traditional craftspeople can adopt 3D tools to sustain and expand their practices, ensuring knowledge is passed on to new generations in relevant ways.

Why This Matters

The fusion of 3D printing with traditional crafts is more than novelty:

- Preservation: Safeguarding heritage techniques by making them adaptable.

- Sustainability: Transforming waste into new materials.

- Innovation: Unlocking forms and structures beyond hand techniques.

- Accessibility: Empowering artisans globally with digital tools.

In essence, 3D printing doesn’t compete with traditional arts – it collaborates with them, giving artisans and designers a new language to express timeless values.

✅ At FacFox, we specialize in turning these cross-disciplinary ideas into reality – from full-color prototypes to ceramic models and bio-composite structures. Whether you are an artist, designer, or craftsperson seeking to bridge tradition and technology, our team can help bring your vision to life.