3D printing resins are tricky to handle, so how do you dispose of resin? Learn what (and what not) to do with this important material.

Liquid resin is the main material used in stereolithography (SLA) 3D printing. SLA uses a UV laser that traces the shape of an object onto the surface of a photopolymer vat. The resin then cures to form layers of the print, and the entire process is repeated until it’s a complete 3D print.

Using a resin 3D printer is very different from using an FDM printer for many reasons, including the unique properties of resin itself. Resins used in 3D printing have toxins and need to be safely handled, stored, and disposed of. Not surprisingly, resins’ toxicity makes the whole process of disposal more complex than with FDM and plastic filaments.

We’ll guide you through the safety precautions that you should take when handling resin, how best to store it, and finally, how best to dispose of it. Safety considerations also have a role in what resin you choose to print with, so we’ll kick things off with a discussion of safer resin options.

Be a good citizen and read on!

Environmentally Friendly Resin

There are a lot of resin options available, but if you’re concerned about resin’s toxicity, you might want to consider using an environmentally friendly resin. These resins are typically bio-based and (theoretically) biodegradable. Noteworthy examples include Anycubic’s line of plant-based resin, Elegoo’s range, as well as 3Dresyns’ offerings.

While all of the safety precautions we describe below should still be followed, eco-friendly resins are far less harmful to you and the environment than regular resin. For usage and disposal guidance, always follow the manufacturers’ instructions.

Safety

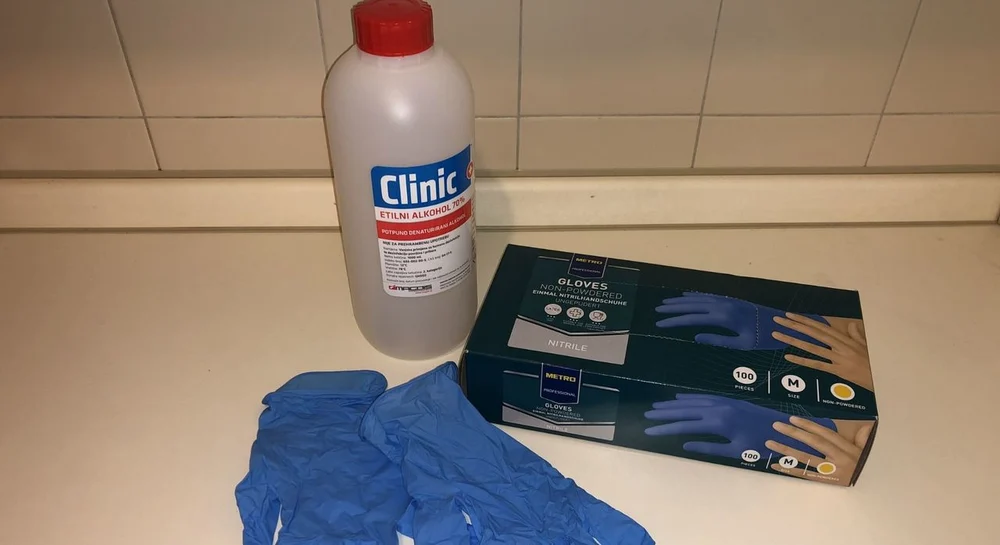

When dealing with resin, you should always wear protective gear. Resins can harm your skin, so whenever you use resin, always wear gloves.

In most places, you’ll be able to choose from latex and nitrile gloves. The latter are better for handling resin because they’re chemical resistant and, of course, will prevent any resin from getting on your bare hands.

Apart from the gloves, you may also want to wear protective glasses, which keep you safe from splashes. It won’t cost you much to pick up a pair, so from our perspective, it’s a no-brainer. You can also use a mask to prevent breathing in any fumes from resin.

Storage

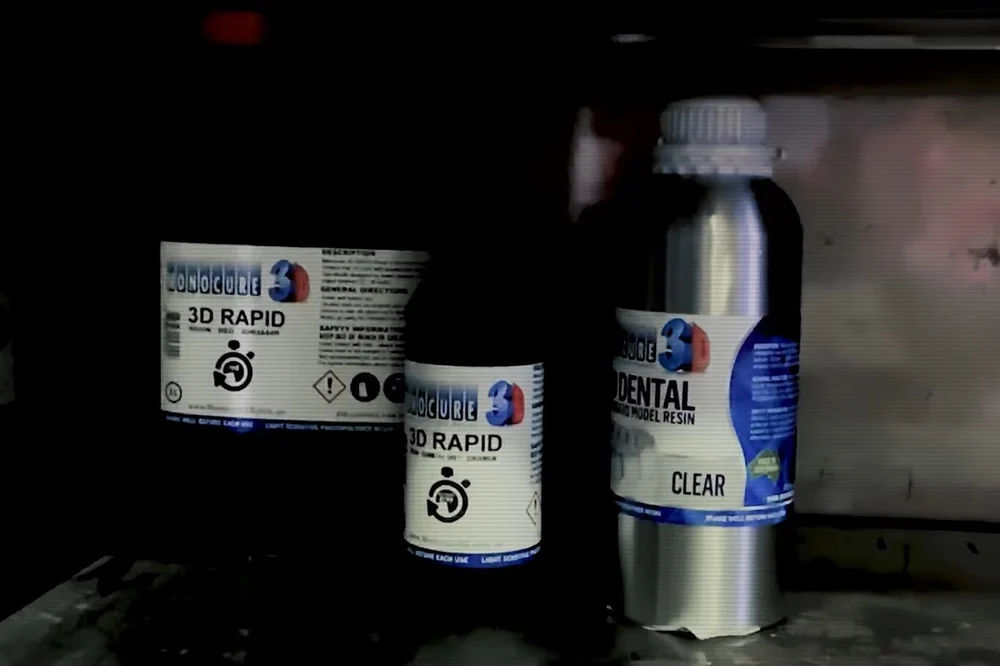

When you’re not using your resin, it’s important to store it correctly. As resins easily react with UV light, resin manufacturers always use black, light-proof containers.

However, it’s also recommended that the containers be kept out of the sun. Putting the container in a cabinet or in a dark place is best.

During Printing

Pre- and mid-printing phases are simple when it comes to handling your resin safely. The most important thing is to make sure you’ve got your gloves on when initially pouring resin into the vat or if you need to add more during the printing process.

Spills can happen when you’re pouring resin, so let’s discuss what to do if that happens. In the end, it isn’t that big of a deal if you have the proper gear to clean it up.

Before you start doing anything with resin, make sure you’ve got some isopropyl alcohol. Cleaning with alcohol ensures all your spilled resin will be removed properly. You’ll also need alcohol for cleaning the vat and the build platform, so make sure you’ve got at a big bottle nearby!

After Printing

The post-printing phase is a bit more involved. It includes removing your print from the build platform, cleaning the vat and the build platform, and also pouring the resin back into its container.

Once your print is done, we suggest you lay some paper towels down around the printer. This will prevent the resin from going directly onto the surface you’re working on. Of course, wear gloves when pulling the build platform out of the printer, as well as when you’re cleaning it with alcohol.

We won’t go through the process of post-processing here, as that’s beyond the scope of this article. If you’re interested, you can read more about post-processing resin parts in our dedicated article.

Water-Washable Resin

It is important, however, to briefly discuss water-washable resins. They simplify the cleaning of resin 3D printed parts but leave residual rinse water behind that contains substances that are very hazardous to you and the environment.

Leftover rinse water should not be poured down the drain. Any residual resin in the water has to be cured prior to disposal, which we’ll discuss in detail below.

Clean Up

After a print’s done, the vat typically contains some leftover resin. This resin can be reused, so definitely put it back into its container.

Open up the container, and put a funnel into the opening. It’s ideal if the funnel has a mesh filter.

Slowly pour the uncured resin from the vat back into the container until the vat is empty. Then use paper towels with alcohol to wipe out any remaining uncured resin. Be gentle when wiping the FEP film so that it doesn’t get scratched.

Curing

Curing is absolutely critical when it comes to resin disposal, so let’s get into what it is and how to do it. When you buy resin, it comes in an uncured (liquid) form, which is good for printing but also toxic!

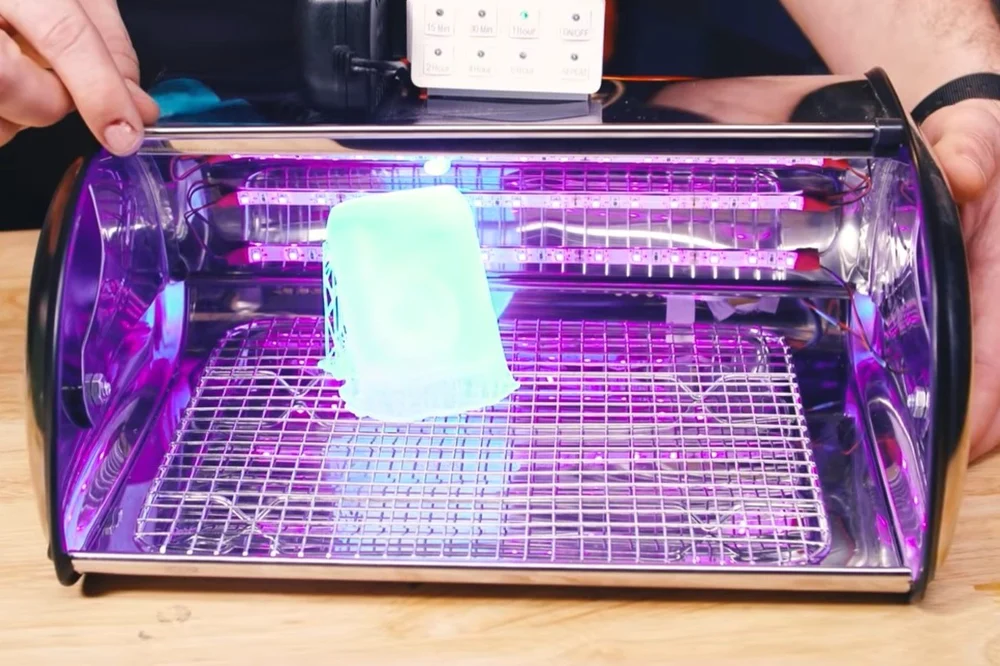

Thankfully, curing is pretty simple and involves heating the resin up or exposing it to sunlight (or another source of UV light) until it’s completely hardened. Basically, cured resin is safe resin.

Once you’re done with printing, your gloves will have some resin on them, as well as the paper towels used. We suggest putting your gloves and paper towels into the sun, if possible, to cure the leftover resin so that you can dispose of that waste with the regular trash.

If you aren’t in a sunny place, there are a number of other ways to cure the resin from your gloves, paper towels, bottles, and prints. All involve turning up the heat, literally, with heat or UV lamps.

Curing simply takes time and depends on the type of resin you’re using. The manufacturer should have information printed on the bottle about recommendations, as well. The most important thing is that the resin dries completely from whatever surface it’s on.

Regarding water-washable resin, prior to disposing of the residual rinse water, it should also be exposed to either sunlight or UV light. Depending on the intensity of the sun, at least a half-hour should suffice. Any residual resin in the water will form as solid particles, which can be strained from the water and disposed of with regular trash. After that, the rinse water can be safely thrown out.

Disposal

In a case where you’d like to throw away a failed print (and the memory of it), be sure to cure it first. When cured, the resin isn’t dangerous anymore, hence why the parts can be touched without gloves and therefore disposed of with the regular trash.

The same goes for resin containers that are either emptied or contain some leftover resin. Always let the resin cure before disposing of it. Simply open up the containers and leave them in the sun or a warm place until they’re completely dry.

Never pour the resin into the drain as it can end up damaging your pipes and, even worse, the environment.

Another option for disposing of resin is to let the professionals do it. Contact your local waste or recycling center to see if they have the capacity to dispose of your waste safely.

Dos & Don’ts

Here’s a quick “Dos and Don’ts” list for you to make sure you’re handling your resin responsibly.

Do:

- Wear gloves and goggles when handling resin throughout your 3D printing process.

- Cure your failed prints, used gloves, used cleaning supplies, and resin containers before disposing of them with the regular trash.

- Contact your local waste or recycling center for help, if needed.

Don’t:

- Handle resin without gloves. (This is really important!)

- Pour uncured resin down the drain.

- Throw away uncured resin.