Clogging – the bane of all 3D printing enthusiasts. Oozing – a lesser known problem often mistaken for the first. So how do you tell them apart? That’s what we’re here for! Read on for tips and tricks that will help you discover whether your extrusion issue is a single jam or something else completely…

The Key Symptoms

Both oozing and clogging have a few key symptoms in common. For one, your printer will be consistently under-extruding — that is, not depositing enough plastic — and your prints will suffer for it.

Second, your extruder may or may not be skipping steps. This may be a result of you trying to compensate for the under-extrusion by increasing flow. If this is the case, back off the flow, and if you notice the other key symptoms listed here, cancel your print. It won’t turn out very well anyway.

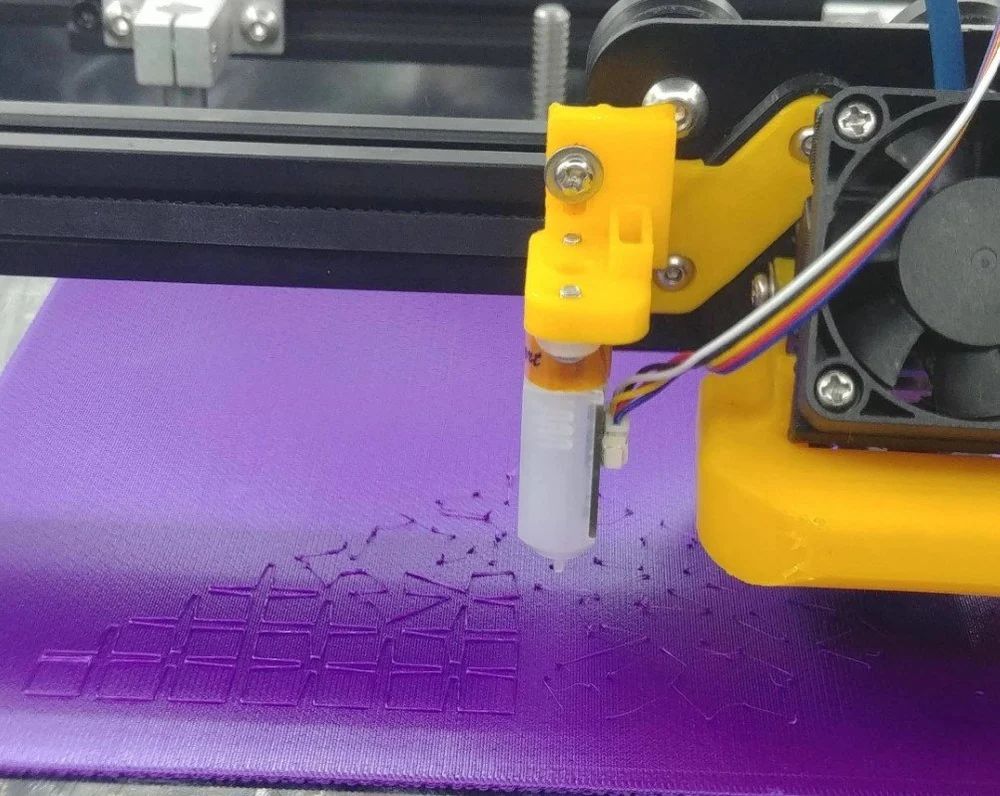

A third set of symptoms, associated more with oozing than clogging, is bad retraction and bridging. This generally manifests throughout a print as irregular blobs of plastic, poor overhangs, and droopy or failed bridges.

A combination of these three symptoms points to a problem within the hot end, especially if other attempted fixes aren’t working. In both cases, the solution will usually involve completely dismounting and cleaning the hot end.

Clogging

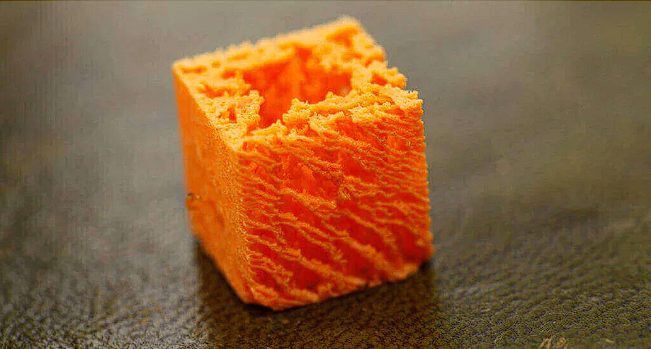

Clogging is caused by particulate blocking the small hole at the end of your nozzle, preventing the flow of plastic. This particulate will either block flow completely or just restrict it enough to cause problems.

Such problems usually occur when using exotic filaments, such as carbon fiber, metal, or wood-infused plastics. However, “normal” filaments, such as PLA or ABS, can also cause nozzle clogging. There are various reasons, including but not limited to filament impurities, dust, and “heat creep”. The solution usually involves a “cold pull” or using a needle to clear the filament path.

You can find full details on unclogging procedures in our article on common printing problems. We also have a guide on how to clean a nozzle.

Oozing

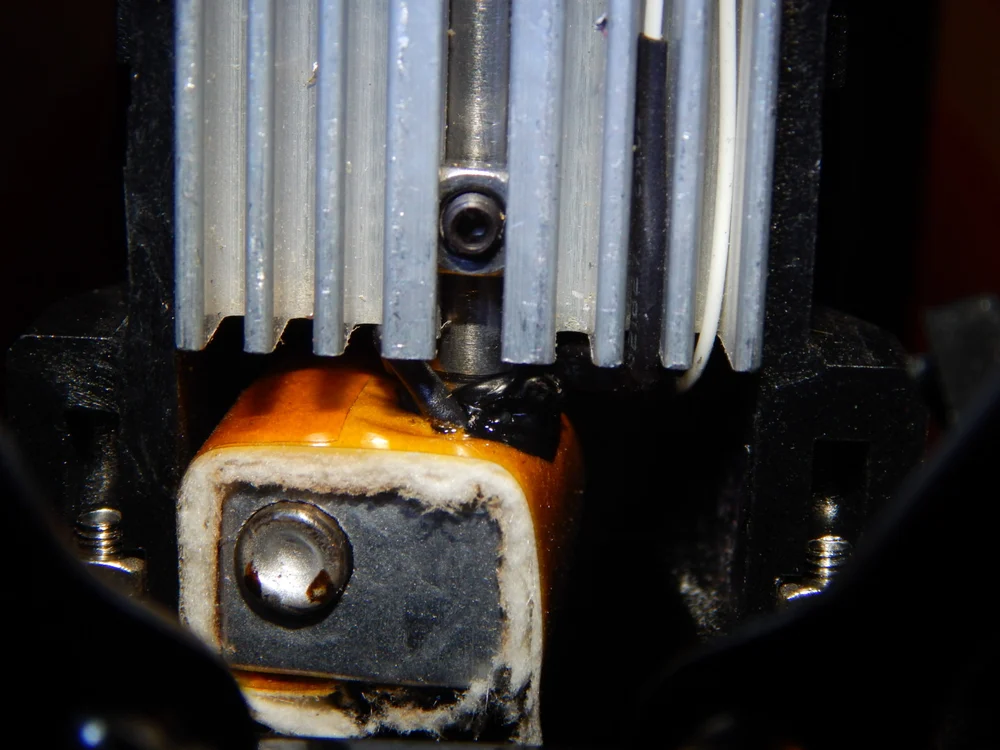

Oozing is generally caused by a badly-assembled hot end. This could mean that the nozzle is too loose or that the heat break consistently in.

Characterized by blobs of plastic forming from the threads of the heat block, oozing can be hard to recognize without disassembling the cooling shroud and insulation around the hot end. Oozing is most common with factory-assembled hot ends, due to poor quality checks.

Unlike a nozzle clog, you can still print with a “leaky hot end”, assuming enough material is being extruded. However, oozing will tend to leave blobs around the print, and under-extrusion often becomes an issue. Undiagnosed, an oozing problem will build up over time and will become a fire hazard if left unchecked.

The solution to oozing is to disassemble the entire hot end, clean it, and then reassemble it. Another option is to replace the hot end with one of a higher quality.

Source: https://all3dp.com/2/nozzle-clogging-vs-hot-end-oozing-what-s-the-difference/