As an alternative to wooden tooling, 3D-printed forms for precast concrete are proving to be more durable and better able to support a large-scale renovation project.

There are certain applications today where 3D printing makes sense. An injection molder might choose to print a small batch of plastic parts that would be cost-prohibitive to mold. A machine shop might invest in a 3D printer to make jigs to aid in inspecting short runs of parts. A service bureau might rely on 3D printing for product development work, as a way to make prototypes quickly and easily.

What these scenarios have in common is that 3D printing makes it easier to produce a small, custom quantity. A few dozen parts. A couple of temporary fixtures. One prototype. There are exceptions, but manufacturers today don’t necessarily see 3D printing as the solution for repeatable, high-volume jobs.

One of those exceptions is proving to be the precast concrete industry. Gate Precast, a supplier of precast structural and architectural concrete, is finding that 3D-printed tooling is exactly the right solution for a job requiring high repeatability over many concrete pours: manufacturing hundreds of punched windows for the façade of a 42-story building in New York City. For this large-scale project, 3D-printed forms have proved their worth in terms of faster lead times, increased durability and better quality in the end product.

Enter 3D Printing

Gate Precast manufactures precast concrete in nine locations nationwide. Some of these facilities focus on structural concrete—weight-bearing items like the beams and columns that make up parking garages—which is produced with metal forms, often in very large quantities. Others, like its Winchester, Kentucky, plant, specialize in architectural pieces which are typically made in smaller batches.

For most jobs, the Winchester plant builds its own concrete forms from plywood and fiberglass through an in-house carpentry department. These forms are not highly durable, but they don’t need to be. A wood form will start to break down, typically after 15 to 20 castings. But for a typical job where only 5 to 10 castings might be needed, this is no problem. It’s larger jobs that are the challenge, when multiple forms must be built to support many concrete pours—which is where 3D printing comes in.

Oak Ridge National Laboratory (ORNL) brought the idea to use 3D printing for concrete tooling to the Precast/Prestressed Concrete Institute (PCI), the industry’s technical institute and trade association, as the result of a collaborative research project. No printing was involved in that project, which focused on developing a lighter, thinner precast insulated panel. But ORNL is famously a co-developer and user of Big Area Additive Manufacturing (BAAM), the 3D printing system now sold commercially by Cincinnati Inc. that uses fiber-reinforced polymer to rapidly build large structures such as automotive parts and lay-up molds for composites.

ORNL hypothesized that 3D-printed molds might help precasters keep up with demand for concrete forms as master carpenters and form builders retreat from the labor force, while also shortening lead times, offering improved durability and potentially reducing costs. To test these ideas, the lab began 3D printing some test forms in a cornice shape which were then sent to Gate Precast’s Ashland City, Tennessee, plant, where between 30 and 40 cornice segments were successfully cast with no deterioration om the tooling.

The Right Job Comes Along

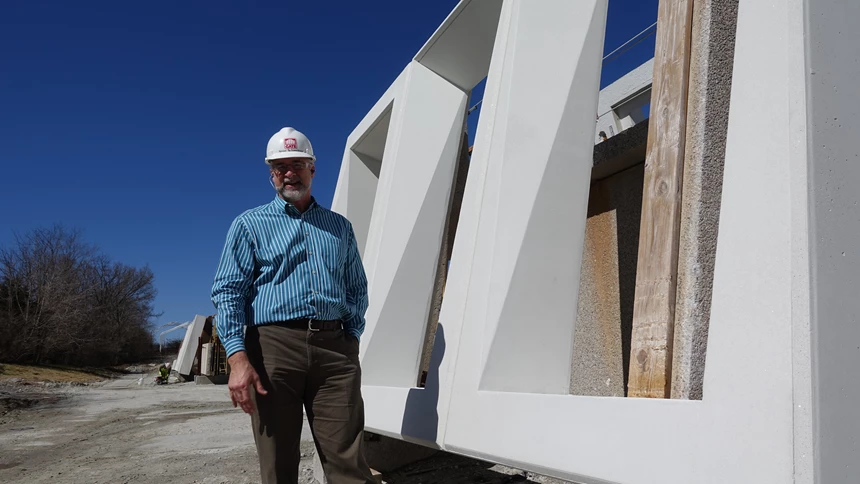

This testing was taking place around the same time that Gate Precast had won a major new job: the production of punched windows for the Domino Sugar Refinery development. This Brooklyn, New York, development will feature several new buildings and recreational space surrounding the historic Domino Sugar Refinery. One of these new constructions is a 42-story complex that includes office and retail space as well as apartments. Gate Precast is making 993 precast concrete panels for the residential portion at the facility in Winchester, Kentucky. (Its Oxford, North Carolina, plant is making an addition 612 panels for the commercial and retail parts of the building.)

Gate Precast won the Domino Sugar Refinery job with a quote based on the cost of making the forms in wood, but knew that this would be a major undertaking. Just to build the wooden forms would have taken 9 months, says Steve Schweitzer, vice president of operations. It wasn’t a given that Gate Precast would be able to build all these forms itself, and farming the work out to subcontractors would likely drive the price up. But with the success of the cornice forms in testing in Tennessee, 3D printing began to look like a viable option.

3D-printed forms may not be worthwhile for a lot of precast concrete jobs. Architectural precast work, like what the Winchester plant performs, can be small batches and one-offs for which a wooden form can be built quickly and cheaply. But the Domino Sugar Refinery project is a job on a completely different scale, illustrating the transformative possibilities of 3D printing for concrete applications. Casting the hundreds of punched windows needed would demand durability and repeatability from the tooling—two things difficult to achieve with forms made of wood.

Gate Precast approached ORNL and Two Trees, the contractor and owner of the Domino Sugar development, to discuss using 3D-printed tooling for the precast windows. Doing so also meant proposing a design change: reducing the number of different window profiles used on the building to make it cost-effective and practical to 3D print the forms. Fortunately, the owner liked the idea of using an unusual technology in the project and approved the change.

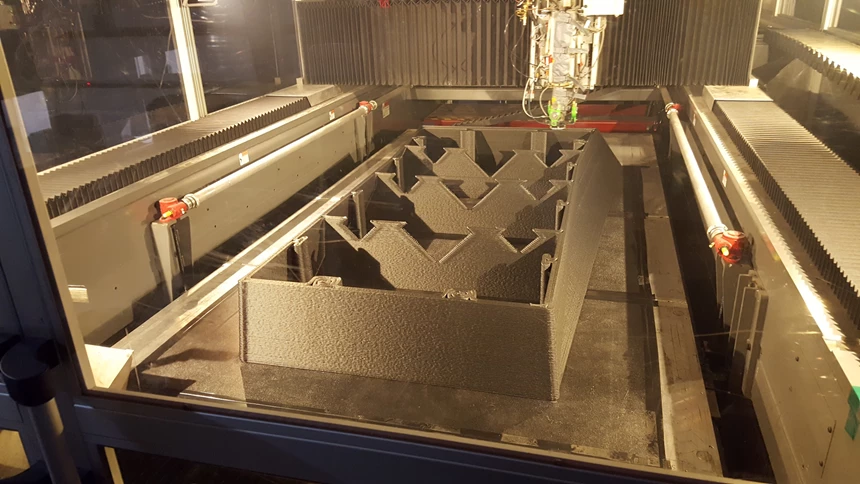

ORNL went to work manufacturing 40 3D-printed forms in five different window profiles at its facility in Knoxville, Tennessee, and eventually Additive Engineering Solutions (AES), a commercial BAAM user in Akron, Ohio, was brought on to help make the forms as well. About half of the forms are being manufactured in each location.

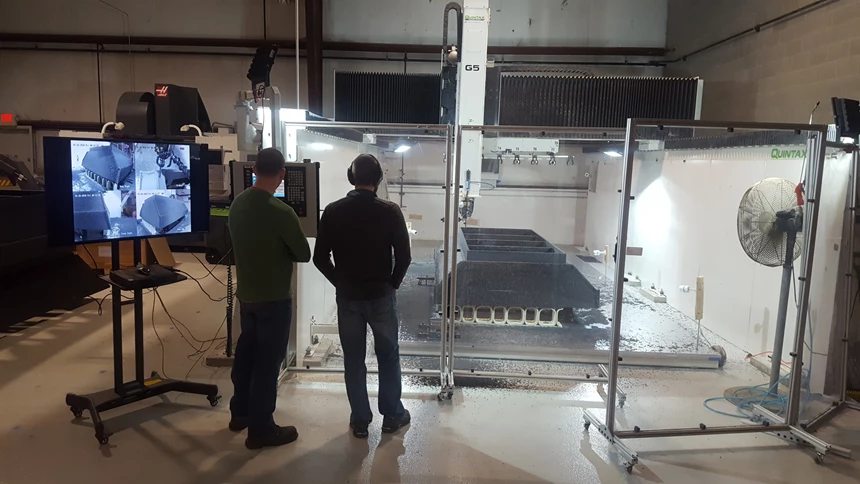

The process starts with developing two CAD models for each mold: an “as-printed” version and an “as-machined” version, says Austin Schmidt, AES president. The “as-printed” model incorporates sufficient stock for the machining process and is fed into the printer as an STL file. Each form weighs between 450 and 750 lbs and takes 8 to 11 hours to print, Schmidt says. Following printing, a large five-axis router machines each form to the “as-machined” model. Light sanding and inspection follows before the forms are shipped to Kentucky.

On one of the largest forms, measuring 104 by 67 by 21 inches, AES enlisted help from Thermwood. The company’s Large Scale Additive Manufacturing (LSAM) system, which features both an extrusion head and five-axis router on independent gantries, made it possible to manufacture this form completely on one machine.

Pouring Concrete with a 3D-Printed Form

In practice, pouring concrete with a 3D-printed form is not much different from pouring with a wooden one. The windows are typically cast three together on top of a large platform in Gate Precast’s Winchester facility. The 3D-printed forms actually represent the front and inner sides of the window cavities, with the outer edges formed by removable plywood walls. Both the forms and sides are treated with a form release oil to help with the unmolding process.

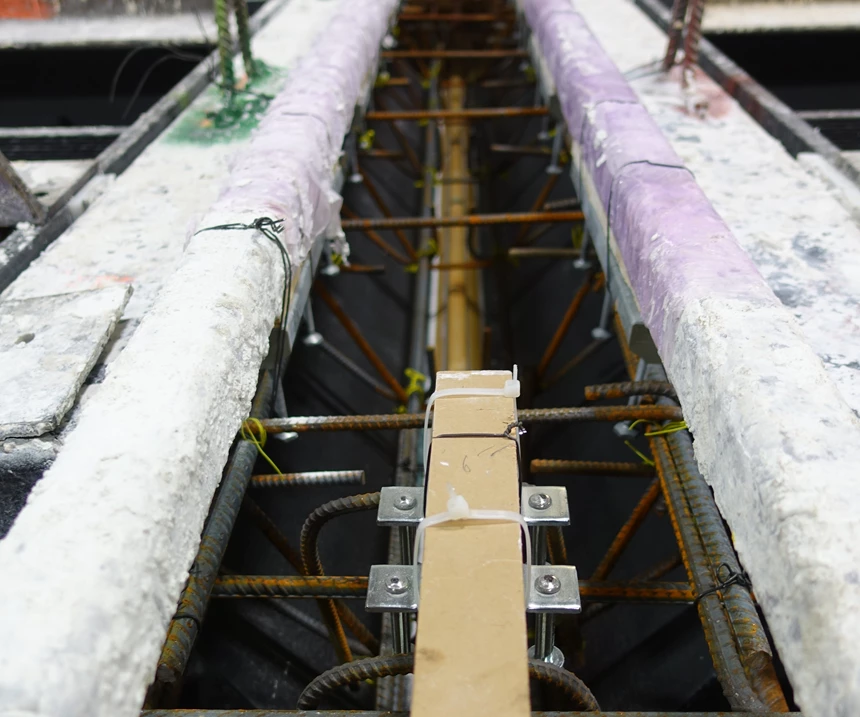

Although they are not structural features, the punched windows still require reinforcement in the form of rebar, which helps to support the windows during stripping and shipping. The rebar is set into the empty form before the pour, along with lifting inserts and tiebacks that will serve to enable shipping, lifting and eventually hold the windows onto the building.

An overhead crane carries buckets of concrete to the platform; it takes about three buckets of concrete to fill one of the three-window forms, Schweitzer says, with each concrete cast weighing 20,000 to 30,000 lbs depending on the profile. The pour stops periodically to allow the platform to vibrate and consolidate the concrete around the rebar, removing any air pockets from the face. Once the form is filled, workers manually smooth the top surface of the concrete (which will be the back of the windows) and clear the areas around the lifting and tieback inserts.

Concrete pours take place each day in the afternoon, and then cure for 12 to 14 hours. The plywood walls are stripped from the cast first, and then the concrete pieces are lifted from the forms around 3 a.m. each morning. Each window frame is manually cleaned with an acid wash spray that exposes the sand in the mix. Then, some of the front faces are polished to expose the sand and aggregate. The resulting finish sparkles—quite intentionally—like sugar cubes.

Finally, before shipping the panels off to Brooklyn, Gate Precast is also installing the glass for many of the windows. This is a new assembly step for the company, says Schweitzer, but a good example of how precast concrete can provide savings in cost and labor by shifting assembly tasks off-site.

Lessons Learned

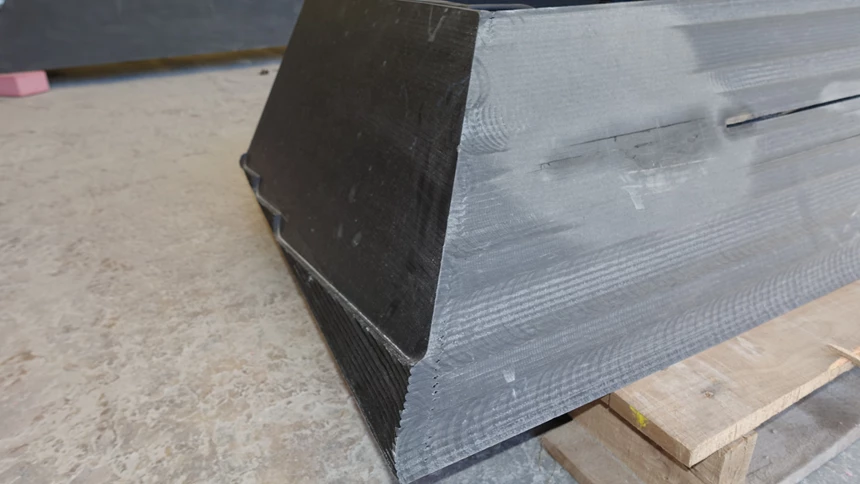

Getting to the point of producing windows with these forms took a bit of R&D. Pours on early 3D-printed forms resulted in what Schwietzer calls “the corduroy effect”—visible bead lines from the 3D print that transferred into the concrete. ORNL solved this problem by increasing the bead size in the BAAM and overprinting the forms so that the excess could be machined down to a smooth surface. Gate Precast also discovered that the bottom faces of the forms were not necessarily square as-printed, so the manufacturers have to flip each form after milling the walls to then CNC the bottom to a flat surface.

AES also cites thermal distortion as a challenge in working with parts of this size. “Even though we are using carbon fiber-filled ABS, the parts still have a tendency to warp slightly,” Schmidt says, “and that must be accounted for during the design process.” (Like Gate Precast, AES typically deals in small quantities but has benefited from the repetitive nature of this job. Manufacturing multiple pieces that are very similar “has given us the ability to really hone in our process,” Schmidt says. “This was a welcomed bonus as we are usually making one-off parts.”)

There were also challenges with some specific features. For instance, one of the window profiles has an indentation in the frame which must be supported by the 3D-printed form. Early forms lacked reinforcement under this feature, and the weight of the concrete caused sagging in the form and final product. It took about half a dozen design iterations to achieve a workable solution, Schweitzer says. The forms for this profile now include ribs under the indentation to support the concrete during the pour and curing process.

Maintenance has also been an ongoing process of discovery. While the 3D-printed molds are far more durable than their wooden counterparts, they still require regular maintenance as they age. “We know we’re going to ding it up,” Schwietzer says, so “How do we repair it?” is a necessary question to answer. The most common maintenance issue is separation of the 3D-printed layers at the bead line, which Gate Precast mitigates with Bondo (commonly used on the wooden forms as well) and the use of a heat gun to deposit polymer pellets (which are then sanded down to a smooth finish).

A Piece of the Pie

Gate Precast estimated that each wood form necessary for the Domino Sugar building would cost between $1,500 and $1,800, and require substantial skill and labor to produce. With the sheer volume of forms needed, this approach would have been costly and time consuming. In addition, a wooden form would be good for about 15-20pours before requiring maintenance or scrapping.

Each 3D-printed concrete form, by contrast, costs about $9,000—by no means a small investment. However, this project should show that a printed form can support as many as 200 concrete pours in its lifetime. For the consistency and high volume required on the Domino Sugar project, the repeatability and durability of these forms makes sense. The 3D-printed forms also provide an aesthetic benefit: Compared side-by-side with concrete casts made on wood forms, the 3D-printed precast window frames can be smoother, with sharper corners.

The project has gone so well so far that PCI has been using Gate Precast as an example for its members. The Winchester plant has hosted several groups of precasters who are interested in seeing how 3D printing can support their work. These tours include representatives from companies that could be considered Gate Precast’s competitors—but that doesn’t worry them.

“Our competitors are not other precasters, but cast-in-place concrete and other materials,” Schweitzer explains. For Gate Precast, “It’s about getting a bigger piece of the building pie, not just the precast pie.” The 3D-printed forms for the Domino Sugar windows are providing proof of concept that could win more of that pie for precast concrete.